From the very beginning this Jaff down-played himself, to the point where I started scrambling to recall who had claimed he was a top farmer; did I have the wrong guy? Even when I arrived at his farm, he still seemed confused by why I’d want to interview him. My low-key panic that I was about to waste a lot of time turned out to be unfounded and, by the time I left, I think even Jaff could see how much value he had to share.

Without planting a single mac tree Jaff has quintupled the returns on this mac farm since taking it over in 2017. He’s REplanted many of the existing trees and continues to improve on the current resources. His fundamental strategy is to focus on the 20% that will make 80% difference. Get comfy for a farmer with a different approach …

Farmer Context – business consultant turned farmer

Jaff was a Leadership and Performance consultant for 20 years and has been far more challenged since becoming a farmer than he ever has been before. “It can easily be overwhelming,” sighs Jaff, “If it wasn’t for the outdoors and the seasons that force cycles and focus on certain tasks at certain times, I’m not sure I’d manage.”

He goes on to explain that corporate consulting is stressful in that you don’t earn unless you’re actively consulting. i.e.: you don’t earn while you’re asleep. But, in farming, you’re managing a self-generating system that is earning while you sleep. As long as you do the right things at the right time, work WITH the system and SUPPORT it, it will do all the work. But, there are stresses unique to farming like weather and other environmental susceptibilities.

Jaff is Zambian-born but attended boarding school in South Africa. His engineering father dabbled in farming and by the time Jaff finished school, Dad had a small dairy and beef operation on the Kafue River. Jaff completed a Dairy Diploma at an agricultural college in the U.K. and then went back to the farm in Zambia. It wasn’t long before he decided to return south and began work on a sugar farm in Wartburg. An unsettled Jaff tried his hand at many jobs over the next few years while getting his SA citizenship and, as soon as that came though, was rewarded with an army call-up.

In the years that followed, Jaff supported his family through everything from ministry to building contracting but eventually settled in Leadership Consulting until his wife’s family called on them to join the family farming operation in Gingindhlovu, on the North Coast of KZN in 2017.

Jaff farms on the North Coast of KZN, near Gingingdlovu

Until then, there had been Mrs Jaff’s Dad, her two brothers and brother-in-law running the farm which had 200 hectares of sugar cane and a fledgling mac operation including orchards and a nursery. Both her brothers were emigrating and her Dad was eager to retire so Jaff and his brother-in-law needed to pick up the reigns. They did this by dividing to conquer. As no one, besides the predecessors, had any mac knowledge, Jaff took this on and left the sugar side up to the competent and established brother-in-law.

With no hand-over to speak of, apart from a few farm records and a wave goodbye, Jaff jumped in. He drew extensively on his corporate training and problem-solving skills to compensate for what he lacked in current farming knowledge. He is eternally grateful for the support from fellow farmers and the staff who taught him what they could.

Farm Context – the struggle is real

Mrs Jaff’s grandfather bought the farm across the road and, later, the farm we are on now. When it was time for the next generation to take over, the larger farm had to be sold to pay out the son who chose not to farm. Mrs Jaff’s Dad was left with this farm; just 270 hectares. He farmed sugar successfully but, as his four children grew up, the scales of decreasing sugar prices and increasing family members began to tip. One son, who had always been drawn to tree crops, decided to give macs a go after a visit to Australia about 25 years ago. And that’s where the mac journey began …

| FARM CONTEXT | |

| Date of visit | 23 March 2022 |

| Area | Gingingdlovu, KZN North Coast |

| Soils | Clay sand, TMS, Heavy clay compost |

| Rainfall | 800ml – 1000 ml annually |

| Altitude | 500m above sea level |

| Distance from the coast | 10kms |

| Temperature range | 35°C – 16°C (max and min) |

| Humidity | Summer – about 90%, Spring & Autumn – about 70 – 80% |

| Varieties | ND, N2, 816, 814, A4, A16, N26, 344, 788 and a few Beaumonts |

| Hectares under mac | 25 hectares |

| Other crops | Sugar (under different management)

Plans for Stevia |

The oldest trees are now 23 years old; 57 trees (a mix of 741, 294, 788) were planted in November 1998. This was followed by 258 more in 2000 (344 & 800 – yes, I also have never heard of cultivar 800 but have some images below …)

Cultivar 800 – first time I’d seen it but it is remarkably similar to its close cousins 816 and 814.

In 2003, 400 Nelmak Ds were planted to create root stock for the nursery that Mrs Jaff’s brother was starting. This orchard still stands today and is a real disappointment – prolific flowers, zero nuts. Jaff is considering top-working.

2005, 2009, 2010 & 2013 saw more plantings; each time in a different spacing and configuration and with different cultivars.

There are many unusual planting configurations throughout the farm

344 orchards planted at 5m x 2m spacing

Right now, Jaff is working with 25 hectares in total, all at different ages, spacings and conditions.

As if this mish-mash of plantings, cultivars and ages were not enough, Jaff also took over when the macs were being farmed under an “Organic” licence. He did his best to keep this going but, after 2 years, an unsound kernel rate of 40% and phosphorous levels through the roof, he threw the towel in.

In at the deep end

Not only was Jaff thrown into the deep end, he also didn’t know what he didn’t know so couldn’t even identify the issues that required attention. It’s been a sink or swim situation but, 5 years in, Jaff has a solid strategy: focus on the 20% that will make 80% difference. For Jaff, right now the 20% is Pruning and Soil Health, so, while we will still cover the myriad of elements that Jaff has built up valuable insight in, these are the key focus points for him.

Establishment … or, more accurately, REestablishment

Jaff never bought, and has no plans to buy, new trees although he will be expanding considerably. All the stock he needs is already in the ground and he will be continuing with the transplanting he began a couple years back. Some orchards here are planted at 5m x 2m spacing and some rows are actually 3 trees wide. While this might seem crazy to us now, remember that, 20 years ago, everyone was learning and there was lots of experimentation. Nevertheless, it has left Jaff with some interesting orchards that he is rehabilitating by thinning them out into new fields.

When Jaff first decided to transplant, he was blissfully ignorant of how fussy a mac tree can be, especially when you disturb its roots, so he went into the task with scant regard for the 816 trees he transplanted in December 2020. Despite this he had an 85% take with this orchard and has since added to his expertise. He’s investigated all the specialist tools on offer and has decided that, for him, the front-end loader on his tractor, together with 2 to 3 labourers, is still the best solution.

This is the team (John Deere plus front-end loader) that Jaff uses to transplant his mac trees

This is his transplant technique:

- Immediately after harvest, the trees ear-marked for replanting are cut right back to about 1,5m, depending on their age.

- The new fields are prepared by taking soil samples and correcting imbalances.

- Jaff has found that a spacing of 8m x 4m is probably best so he cuts small ridges to suit.

- The land then resettles during a fallow period.

- The day before transplanting, Jaff opens up the holes for the transplanted trees – he can do about 8 to 10 per day. These are filled with water and a gentle organic fertiliser mix.

- Also the day before, the front-end loader opens up around the tree to a depth of about 50cm, leaving about a cubic-metre bulb, depending on the size of the tree. This is filled with water to help soften the soil that the labour will have to move the next day.

- Then the time comes for uplifting the tree. The labour help to loosen the roots, using 3-pronged picks and spades, and the tree is scooped up by the loader with a concentrated effort on keeping as much soil around the roots as possible.

- The tree is moved to the new orchard and carefully placed in the open hole.

- Jaff does not worry about the tree facing the same way it was before he moved it but he has learnt that the tree must not be planted any deeper that it was before. If it is, it will almost certainly die.

- He also makes sure that the amount of leaves does not exceed the amount of roots and cuts the leaf growth back if necessary.

- The hole is then covered and the trees are watered every few days. (Jaff runs a DRY farm)

“I have learnt that mac trees are tough,” says Jaff gratefully, “but maybe December isn’t the best time to transplant.”

Visual illustration of the “transplantee” preparation

Water – or the lack thereof

Before you think we’ve covered all the obstacles to Jaff’s farming dreams, consider that this is a dryland farm! Yes, there are 6 hectares that had irrigation when he took over but it was non-functional. He spent much time and energy restoring this whole system and, in that time, realised that he didn’t really need it.

The rainfall here is predominantly summer-based but there is a fair amount in winter too. The only really dry months are late summer, shortly before harvest. So, while Jaff has his finger poised over the irrigation switch for 6 of his 25 hectares, he hasn’t yet flicked it on.

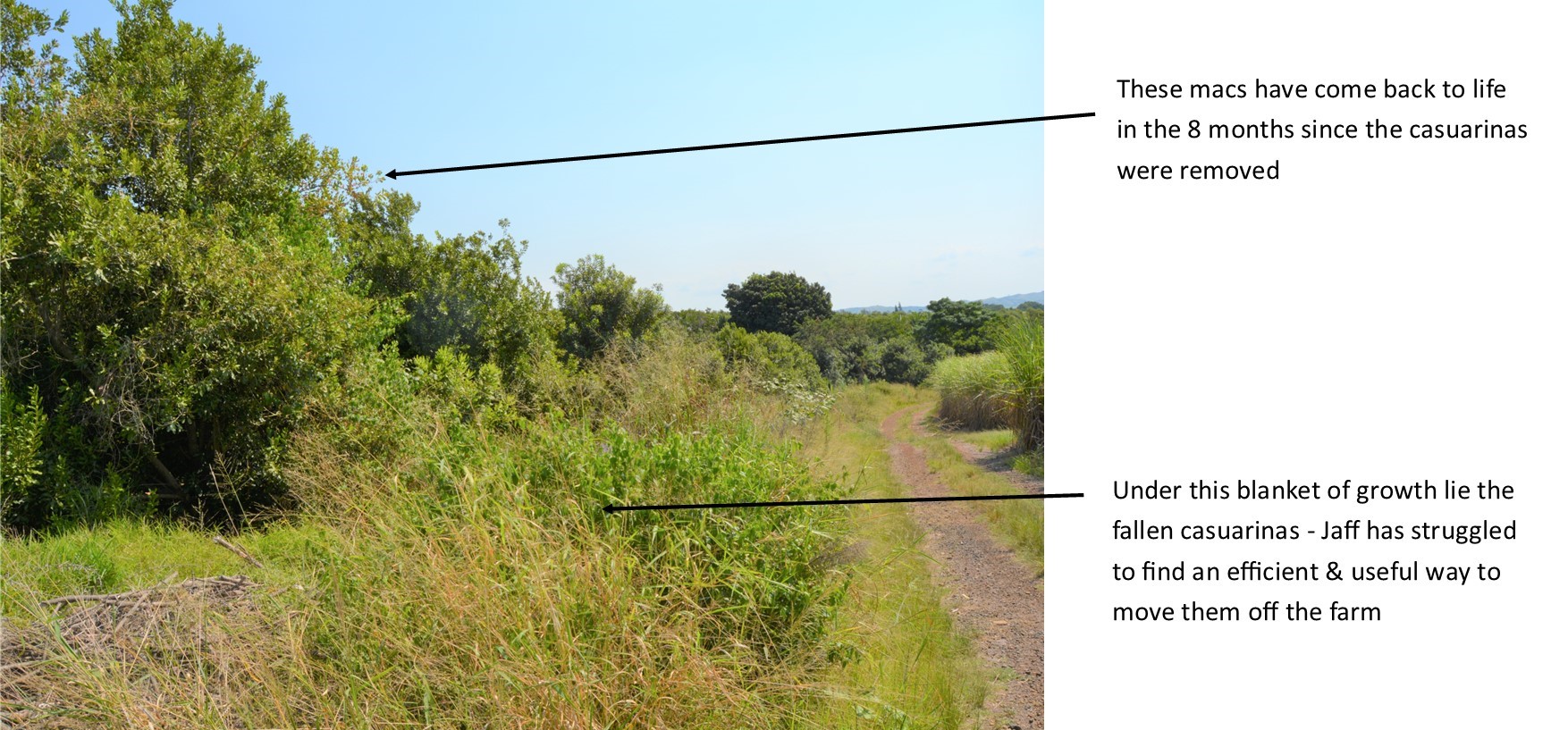

Whilst restoring the irrigation system he discovered how horribly destructive the numerous casuarina trees planted throughout the orchards had been. In some places, he found their roots through pipes that were 200 to 300m away from the closest tree. This issue, coupled with the fact that many of the mac trees bordering the casuarinas were no more than bare branches, he embarked on a mission to rid the farm of all but the necessary casuarinas.

In some places there were 3 rows of casuarinas “protecting” the macadamias. Unfortunately, they were doing more harm than good and Jaff has removed 90% of them. The macs that were in their shadows have since recovered remarkably.

Having arrived on this farm shortly after the devastating drought that broke in 2016, Jaff has witnessed the resilience of the macadamia trees here, “The trees don’t die when it’s dry, they just slow down.” Although that might not be the case for trees used to constant irrigation …

Does Jaff plan to extend and make use of the irrigation? “I’ve decided to be a little more conservative in what I throw at the trees,” replies Jaff, “After much consultation of specialists, I’ve come to the conclusion that irrigated trees are not synced with nature and, if nature is what I am going to rely on for optimal soil health, I need to embrace the programme fully.”

“I understand that my yields will never compete with the industry’s best but I honestly feel that our impatience and ambition demands too much from the trees; what we get in increased yield, we lose in environmental sustainability. I just don’t know enough to walk that tight-rope and need to partner with nature if I am to shepherd this lot through the long-term.”

Despite this, Jaff does appreciate the value of having the 6-hectare irrigation system functional; just in case nature turns nasty …

These are the oldest trees on the farm, at 23 years and look incredibly healthy for completely drylanders

Feed the tree or create the environment for it to feed itself?

A natural follow on from the previous topic takes us into the first of Jaff’s 20% focus areas: Soil Health. There are 2 reasons why this makes complete sense to me: 1. Jaff’s son has just completed a degree in soil science, and is currently doing his Masters, 2. Farmers who have been at it for generations are still confounded by the overwhelming options and complexity of nutrition management (actually, most of us can’t even feed ourselves properly …) so how much more was this world of fertilising going to be too much for Jaff!

And yet I think he’s seen it more clearly than anyone I’ve ever interviewed before … and he summed it all up in this statement; “Putting fertiliser into unhealthy soil is like driving a car and having your feet on the brake and accelerator and the same time.” Don’t know about you but, for me, that hit home!

Jaff has some good soils but most tend towards the sandy aspect so he is focused on increasing the organic content

Jaff has a unique approach to feeding his trees:

- His focus is primarily on soil health – minimal disturbance and additional organic matter.

- Then he relies on leaf samples, rather than soil samples, to identify what to supplement and when.

- If shortages/toxicity persists he considers influencing/inhibiting factors in the soil.

Jaff has also decided to move away from granular fertilisers, based on 2 main reasons:

- Theft of the granular product was a concern.

- Effective application. When Jaff first arrived, the staff were filling tins and throwing the contents under the trees. While this works with the right technique, Jaff couldn’t seem to get his staff skilled and he was concerned about the inefficient use of such an expensive input.

Jaff currently orders liquid fertiliser and applies using a modification on the spray rig.

The adaptions on Jaff’s spray rig allow him to use lance sprayers, with calibrated nozzles, to apply liquid fertiliser on the root zone.

Moving to liquid solved these concerns but has put excess pressure on the spray rig so Jaff says he will probably have to manage with a combination of granular and liquid fert until he can invest in another spray rig and additional operators.

I was intrigued to know how Jaff will decide what to use where in this “hybrid” plan … “I use granular in orchards where there is a full canopy, and broadcast it with the lime spreader I bought last year. The younger orchards get the liquid because their root system is much smaller and the liquid can be applied in a targeted way.”

Jaff invests in one new piece of equipment each year. This was last year’s purchase and has been useful in lime, gypsum and fertiliser applications.

Jaff invests in one new piece of equipment each year. This was last year’s purchase and has been useful in lime, gypsum and fertiliser applications.

Being old canelands and then organic orchards, Jaff has inherited soils plagued by high levels of phosphorous which, as we know, is quickly toxic when it comes to macadamias. The consequence is that his use of organic fertilisers is now limited as these almost always have inherently high p-levels.

Almost all macadamia farmers face a common challenge right now; finding the sweet spot between what the fertiliser consultants recommend, what the resources will allow and what makes the most sense for the long term … perhaps there is one big question to ask:

Will the R1 I am spending on this product* bring a return greater than R1?

If not, there’s no point. (*include ALL the costs eg: remember labour, fuel and equipment required to apply the product as well as any hidden costs that will rear up later eg: pest issues, chemical imbalances, sustainability limitations.)

Jaff is navigating this tight rope brilliantly; he listens carefully to the consultants, as the experts, but he also consults the trees, by way of leaf samples. If these show that the trees are lacking anything, he allows the consultants to advise on the best way to supplement.

The incredibly large leaves of the Nelmak D can be seen in this growth from the root stock

The incredibly large leaves of the Nelmak D can be seen in this growth from the root stock

Leaf samples measure a range of elements and give benchmarks of what the levels should be so Jaff can see where the shortages are. Last season, the leaf samples indicated that all the trees were well-fed. Despite this he still gave a full application of nitrogen, potassium and micronutrients in Nov / Dec just to make sure they remained happy through the harvest. As he gets more familiar with the trees he will rely more and more on the natural bank he believes the enriched soil is building up as he continues to add mulch.

Jaff is using a chipper to convert pruning into mulch. He also composts the mac husks together with the sugar loading zone scrapings. Excessively long grass in the orchards is cut down and will be spread under the canopy now that he has his latest piece of equipment that was delivered yesterday.

This brand-new mower/mulcher with a hydraulically adjustable arm will increase farm efficiency as it replaces the brush cutters

This brand-new mower/mulcher with a hydraulically adjustable arm will increase farm efficiency as it replaces the brush cutters

This very impressive chipper’s contribution to soil health is already clearly evident in the increased organic content of the (mostly) sandy soils

This very impressive chipper’s contribution to soil health is already clearly evident in the increased organic content of the (mostly) sandy soils

No macadamia story would be complete without a mention of phytophthora … and yes, Jaff does have clear indications that this bacteria is present. But, in line with his 20/80 principle, he has chosen to address it through the focus on soil health.

Rethinking Unsound Rates

The discussion around pests was another profound insight for me; Jaff’s simplification of a complex issue was refreshing. “Be careful not to be caught up in someone else’s unsound targets,” cautions Jaff, “focus on your targets, driven by your goals.” If getting the factory prize for ‘least unsound’ is important enough for you to nuke your orchards, go ahead. For me, I aim only to avoid factory penalties (the factory penalises you if you deliver anything over 3% unsound) whilst still maintaining a self-sustaining, ecological balance in the orchards.”

Jaff adds that the ‘least unsound’ is not the only prize he won’t be winning … he also fails to qualify for the most manicured farm award, for the same reasons. Having married into a German farming family, you can appreciate the involuntary twitches this strategy has induced back at the homestead …

But Jaff is steadfast in aligning with nature to minimise pest damage and was incredibly proud of his “messy” orchards and all the lacewings, wasps and spiders he nurtures therein. Of course, I am an ally in this regard!

Jaff admits that he has lots to learn when it comes to beneficial insects but he knows that spiders, wasps and lacewings are good and proudly shows me evidence

Jaff admits that he has lots to learn when it comes to beneficial insects but he knows that spiders, wasps and lacewings are good and proudly shows me evidence

So how does Jaff keep pest damage down? There are 3 key pillars to his strategy:

- A systemic drench at the start of the season

After flowering Jaff applies a systemic drench to all the orchards. This deals with all saprophytes (insects with a probiscis) for about the next 5 months. It is a nicotinoid and therefore far from ideal but I suppose nothing is … Jaff has heard it will possibly become banned shortly and he’ll need to adapt.

- “Messy” orchards

As mentioned, Jaff leaves the orchard vegetation to grow and create an environment in which to host insect life. He mows just before applying fertilisers so that the application of these supplements is not hindered by the growth.

Jaff’s “messy orchards” really weren’t all that messy but you can see how nicely the new mower will work as it angles up the ridge and fits neatly under the mac skirts. He only mows the centre piece in November.

- Scouting

It is clear how passionate Jaff is about scouting and explains his approach clearly:

- Stink bugs: Knock-down is applied to 2 – 3 trees, usually in the densest parts of the orchard. If he were to find more than 4 bugs per hectare, he would spray the whole orchard but this hasn’t been necessary in the last 2 seasons – Jaff puts that down to the pre-season drench.

- Moths (both FCM & MNB): This is a bigger concern for Jaff currently and the scouting traps seem to have been ineffective this season (verified by the suppliers and other farmers) giving false indications of the actual presence of these pests. When he realised that the counts were actually too high he did a blanket spray of the whole farm in November and hopes that the damage to his crop was minimised through this intervention.

- Thrips: Jaff is certainly not alone in the dilemma of how to deal with this one … he once hosted an entomologist on the farm who advised that these insects do more pollenating than the “over-rated” bees. Yet, other specialists have told Jaff that the thrips are eating his flowers … He’s come to the conclusion that both are right as there are many types of thrips and, in his typically conservative style, has decided not to spray them, relying instead on the pre-season drench and pruning to minimise any damage. He says he finds most thrips in the dense orchards.

An older Nelmak 2 orchard in need of some pruning after the harvest ends

Pruning is biblical

I was surprised to learn that pruning is mentioned no less than 10 times in the bible. Rather difficult to ignore when it comes from such a rich resource with ancient roots!!

For Jaff, it is the second of his two big focus areas (the 20/80 principle).

He chose this because it:

- creates the necessary capacity for the trees to deliver optimal yields

- aids in the fight against pests

Jaff’s strategy is to bring the tree height down to 70% of the row width and to take out key branches that will open up windows and stimulate growth (bearing wood) within the tree. At first, he was only addressing tree height but quickly realised that the “witches’ brooms” that shot out from these top cuts closed off sunlight into the rest of the tree which impacted bearing negatively. To rectify this he had to go back and implement part 2 of the strategy; large limb removal.

Jaff has deep respect for the pain that comes with pruning and has had to deal with compromising his short-term yield in favour of long-term benefits. To put this in to numbers, his 2020 season was down by 2/3 because he pruned aggressively that year but is now seeing the benefits and will continue with the strategy.

I noticed that some of Jaff’s orchards had really low skirts and some were rather high; these are all a result of natural cultivar growth patterns and Jaff realises some need attention soon, “the A4s & A16s have very low branches which makes the harvest awkward for our people. It also restricts mower access so I’ll be adding skirting to my pruning strategy to address these issues,” says Jaff.

A mature A4 orchard showing its characteristically willowy branches and low skirts. You’ll also notice the multiple-tree-per-row planting pattern again

There were two small tips that I picked up from the detail of Jaff’s pruning that might be helpful to some:

- Jaff built a small platform that attaches to the front-end loader bucket that we saw earlier – the one he uses to transplant trees – the pruner will stand on this while the tractor operator raises the platform up into the tree tops thereby giving the pruner clear access.

- To avoid mistakes, Jaff went through 3000 trees last season, marking, with paint, which branches should be removed by the pruning team. Whilst he found this method effective, he did develop tennis elbow and will be using a brush extension this year.

Cultivars that work

With such an array of cultivars on the farm, I looked forward to some valuable insight on what is working well and what isn’t but Jaff confessed that he is not ready to fully endorse nor discount any of the cultivars because there are just too many factors at play while he straightens the farm out and learns his way … except maybe Nelmak D … Jaff really doesn’t like them … “They give such a gorgeous show of flowers but too few nuts!” laments Jaff, “but I do understand that they were planted, by my brother-in-law, for root stock seed, not kernel.” Nevertheless, Jaff is seriously considering top-working this orchard soon.

All- talk-no-walk Nelmak Ds

When pressed, Jaff admitted that 816, 344, 788 looked like the best achievers on this farm, along with Nelmak 2. Even A4 & A16 produce well but Jaff is a little put off by their very strange growth pattern – which is understandable given his current focus on pruning ….

Besides Nelmak D, Jaff is also not very impressed by Beaumont. Although he doesn’t have very many of them and admits that the ones he does have are in the very worst soils; he suspects that Beaumonts are best suited to nut-in-shell consumers. With China being the largest nut-in-shell consumer, and a shrinking one for SA growers, he is glad that there are not too many of them on his farm. Jaff also has concerns that the factory has to process these nuts separately, even from other hybrids, because of their unique profile – for him, this is a red flag.

Harvesting and processing

Jaff comments that, for some unknown reason, his harvest has moved earlier each year. This year he started picking on 20 Feb and expects to be done by the end of May.

Having so few Beaumonts, he has never used ethapon. He knows the 788s will be ready first and, when the husks turn brown inside, he starts the harvest.

Jaff was initially advised to cut the grass and sweep the area under the trees clear so that the harvesters would be able to see the nuts clearly. Although he followed this advice at first, he soon developed his own technique which he feels is far better for 1. His wage bill and 2. the fine feeder roots in the soil surface that would die within hours of exposure. Now he doesn’t even mow under the trees before harvest. Instead a team will clear the orchard floor of all fallen nuts. Then long lengths of shade cloth, up to 6m wide, are lain on either side of the row, as shown below.

Shade cloth sheets laid out under the trees before harvest

Once the sheets are down, the men come in with bamboo poles and knock the nuts down. Jaff explains that he tried many other tools for this job, like hooks and rakes, but found that these tend to tear and break branches, whereas the bamboo does the same job with less damage.

As the men move through the orchard, the women follow and pick up the fallen nuts, putting them into crates.

Jaff’s preference would be to allow the nuts to fall naturally but theft has forced him to pick, stripping the nuts before the thieves do. Afterwards, he may send a team back to glean the floor once (the bushpigs usually get there first) but, apart from that, his harvest is a single pass through each orchard. Being a small operation, running a 10-member harvest gang is an expensive line item so he works hard to guide them to a balance between getting every last nut off and making efficient use of their time.

The afternoon I was there, the team was gleaning the 816 orchard floor

Soon after the 788, the 344 and 816s and other integ varieties start to ripen.

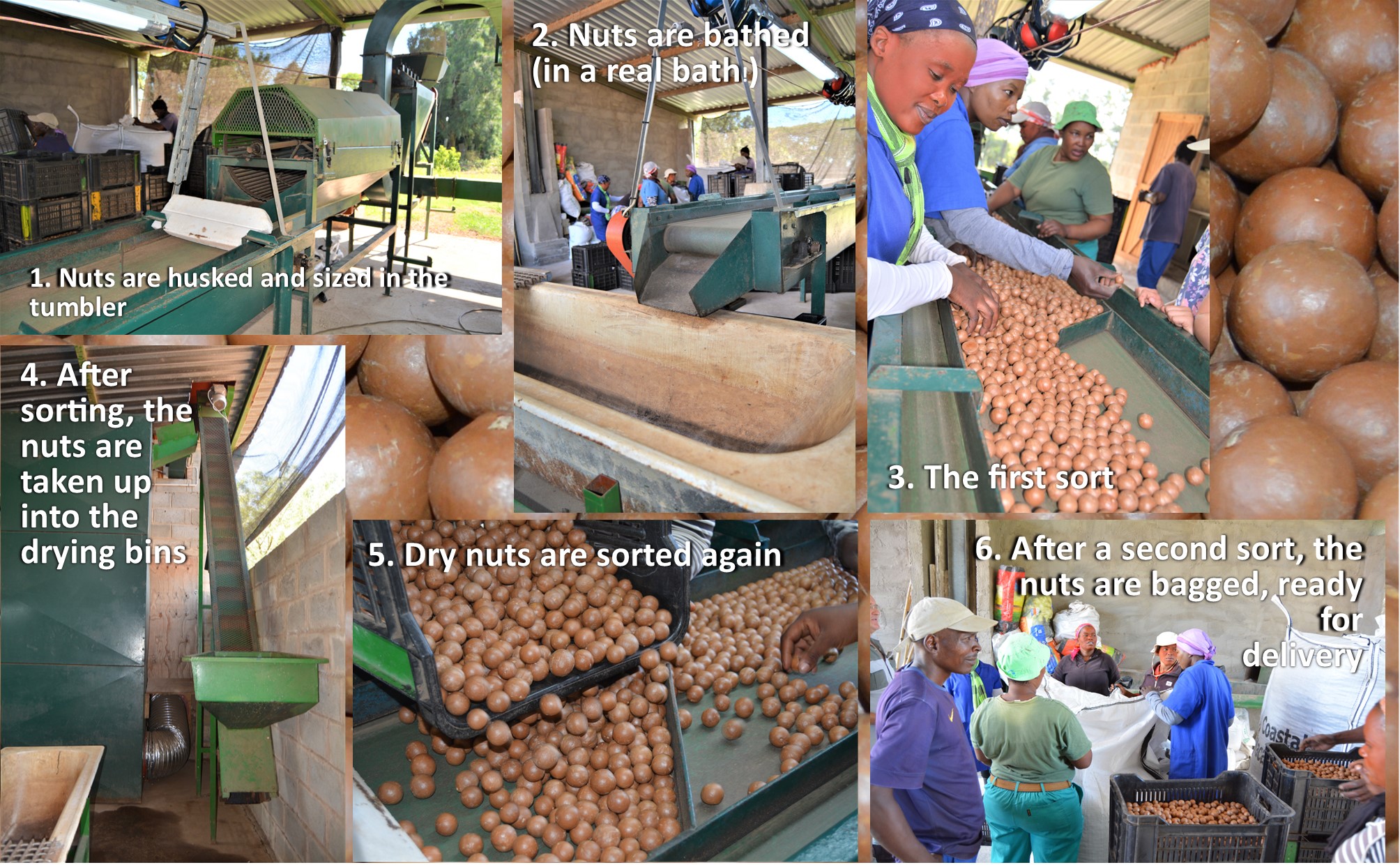

From the crates, the nuts are tipped into a trailer and taken to the dehusking and sorting plant. Once husked, they are tumbled to exclude the smalls and bathed in an anti-fungal and anti-bacterial wash to both treat, and float out, the immatures. From there they are sorted and placed in the drying bins.

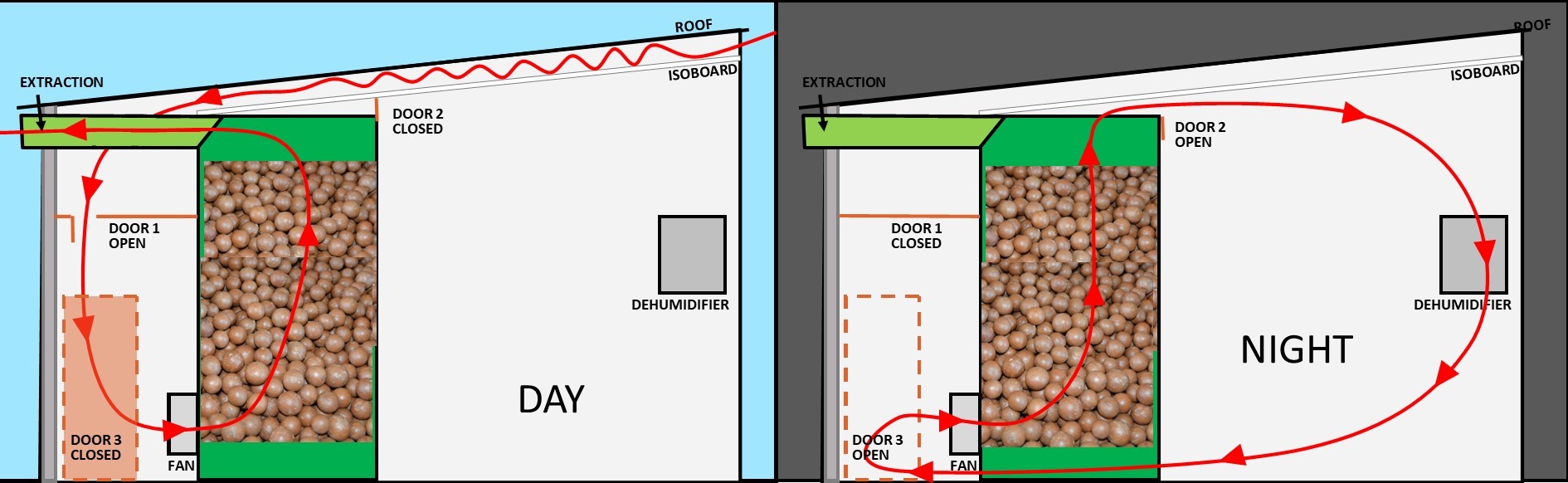

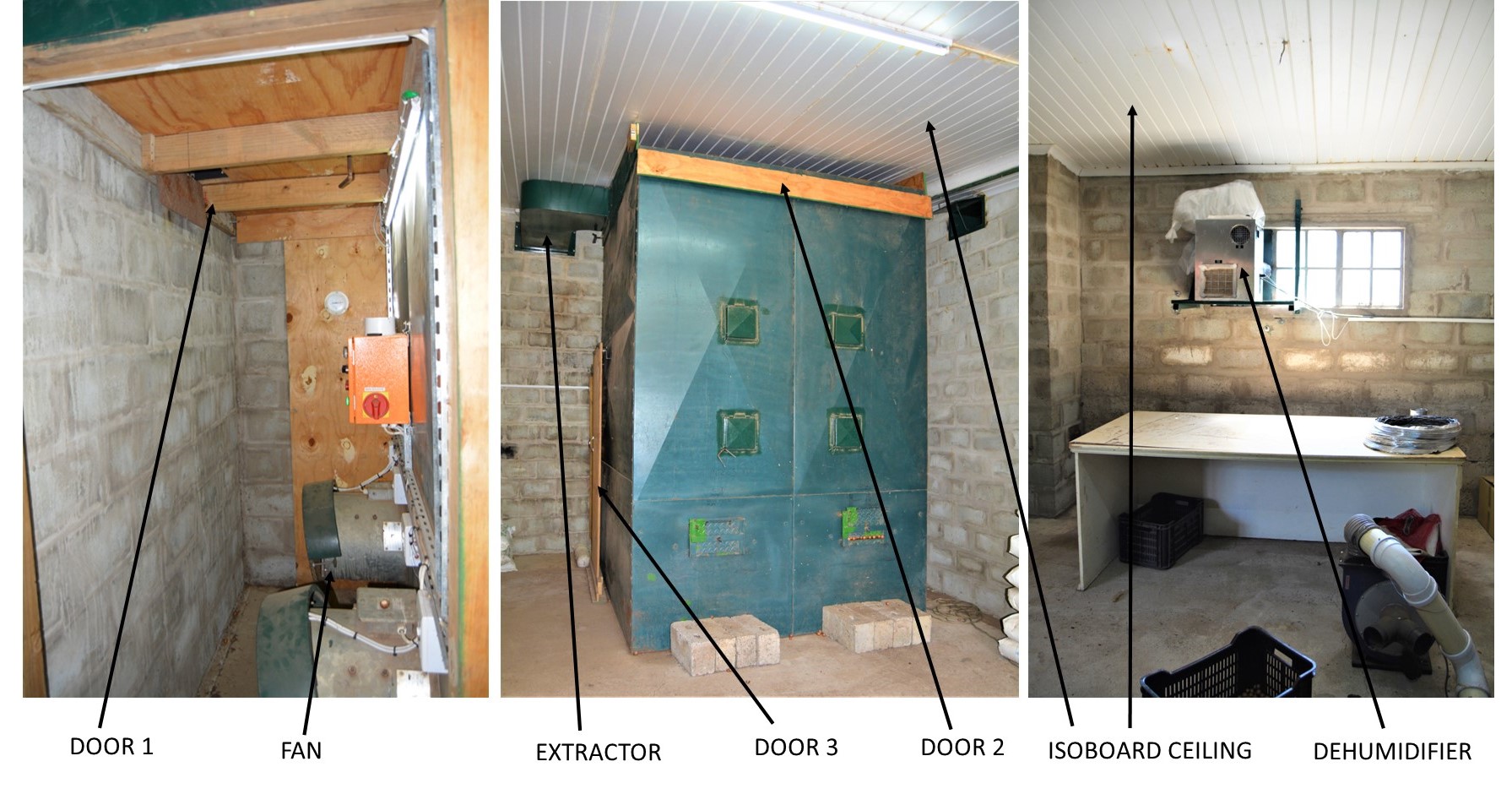

Jaff has 3 x 4 tonne bins fitted with fans. During the day he uses air, heated between the roof and an isoboard ceiling, to dry the nuts and, at night, by closing two doors, he diverts the airflow through a dehumidifier and uses only the air in the room.

Jaff makes brilliant use of naturally heated air to dry the nuts, keeping the process going through the night with dehumidified air

During the day, the temperature of the air going through the nuts can get up to 40°C. Within 5 to 7 days the nuts are down to 2% moisture which is what Jaff delivers to the factory at.

To accommodate growth, Jaff has set up another bin, just outside this shed that channels the same air through its system.

Once the nuts are dry, Jaff sorts again, explaining that the defects like moth damage are so much more visible on a dry nut.

One tip Jaff has learnt and is happy to share is that the hybrid nuts (Beaumont, Nelmak, A4, A16 etc) seem to crack when they are dried to this moisture level so, this year he will exclude the heat and dehumidification from their cycles as the factory does not accept cracked nuts, however benign they might be. Up until now Mrs Jaff has gratefully accepted all these “rejects” into her kitchen from where she shares and makes the most unbelievable bread (inc macadamia nuts) I have ever tasted!!! Recipe at the end …

People Management

Knowing that Jaff comes with decades of Leadership training, I was eager to hear his tips on people management … he explains that it all hinges on culture; “Strategy is worth very little if you don’t have a culture that can execute on that strategy.” When I looked a bit blank, he went on to explain how he’s gone about instilling a culture here;

- We have a board up, with all the disciplinary codes clearly detailed. Everyone understands that this is minimal acceptable behaviour (M.A.B.). But the focus is not on this.

- Every morning we meet to share a devotion, with a practical application of the lesson, and prayer – this sets the tone for our culture.

This has worked in two ways; 1. If anyone contravenes the M.A.B. then we simply go to the board (the whole team) and follow the rules. Not my rules; government rules. The consequences are followed to the T and we move on. 2. The culture developed through the morning devotions has naturally worked out anyone who isn’t aligned to it.

Beyond that, Jaff is furiously trying to improve his Zulu as he knows this will go a long way to improving his people management.

A happy and healthy farm; plants and people

Equipment

As mentioned, Jaff has invested in one piece of new equipment each season which gives him time to prioritise and research exactly what he needs. So far he’s bought the sprayer, chipper, spreader and mower/mulcher. Most of the tractors are John Deere but there is also this incredibly special old soul …

This retired 1950 Robuss is now used only to take Mrs Jaff’s 87-year-old father for drives down memory lane

And that brings us to the end of a really insightful and pleasurable day with the Jaff who thought he wasn’t a Jaff.

Macadamia bread recipe (verbatim, from Mrs Jaff)

So with regards my bread recipe…it may need to be tweaked as I made it out of my head.

Normally my ratio is 3c of flour to 1.5c warm water/milk.

In your bread (yes, I got a loaf all for myself – pictured above) I added a few extras like a handful of dates, a hand full of mixed seeds, a cup crushed dried macadamia nuts, and threw in some spelt.

A white flask mug is my measure and I use a Kenwood mixer.

I have a small Anvil thermofan oven, which for me works the best.

Ingredients:

2 cup Eureka Bread flour

1 cup Eureka Cake flour

1 cup organic spelt (optional*)

1/2 c wheatgerm

1/2 cup chopped dates

1/2 cup mixed seeds

1 cup crushed dried macadamia nuts

1 1/2 sachet yeast

1 tsp salt

1 Tbsp sugar

1 cup warm milk

1 cup warm water

*If you don’t have spelt just replace with cake flour.

Method:

1. Place water, sugar, spelt and yeast in a mixing bowl. Mix, seal with glad wrap. Store in fridge overnight.

2. Place all dry ingredients, including dates and crushed nuts in a larger bowl. Add spelt mixture and warm milk.

3. Mix well.

4. Allow to rise and beat back.

5. When dough becomes ‘elastic’, place in two separate medium baking tins, previously sprayed with non-stick spray.

6. Sprinkle dough with additional seeds.

7. Allow to rise to double.

8. Bake in an oven preheated to 180’c for 1 hour.

Then Mrs Jaff mentioned that, once the loaf is baked, she brushes the top with coconut oil to prevent fungal and bacterial infections.