| FARM CONTEXT | |

| Date of visit | 21 June 2022 |

| Area | Tala Valley, near Camperdown in the KZN Midlands |

| Soils | Sandy loam, Huttons (40%+ clay), complete mixture. Jaff chose the best soils for macs, avoiding the sandy soils. Since he saw them growing well in sandy soils in Nelspruit, he has planted in these poorer soils and learnt that the macs probably prefer sandier soils. |

| Rainfall | 550 – 600mm annually |

| Altitude | 650m above sea level |

| Distance from the coast | 50kms |

| Temperature range | Average 6°C – 30°C but can go to -6°C and up into the 40s |

| Varieties | Beaumont, A4, A268, 863, 788, 816, 814, 842, 849, Nelmak 2 |

| Hectares under mac | 230 hectares in KZN & 300 hectares in Mozambique |

| Diversification | Sugar cane, Kiwis, Cattle, Veg |

This Jaff visit was a huge achievement – for all of us … he’s a farmer in an area where I haven’t been able to see many farmers, he’s been in macs for a long time and has scaled his operation successfully – all round an EXCELLENT Jaff. Very grateful to be able to share his operation with our readers.

THE ROAD TO MACS

Jaff’s ‘tribe’ originate from the Harrismith area where both his father and grandfather farmed. From there they moved to Hoedspruit, farming potatoes, maize & wheat but the financial disaster (and subsequent exorbitantly high interest rates) in the early 80s saw them go out of business. Jaff was 15 at the time and had to reconsider his youthful dreams of continuing the family farming vocation. When he left school, he decided to do a BComm and then travelled the globe for the next 2 years. When he finally returned home, his uncle, who was leasing agricultural land in KZN, invited him to join forces. In 1994 they bought a veggie farm just down river from where we sit today; they got the farm at a great price and made a real success of the operation. A few years later Jaff bought this farm – it was an old dairy farm but Jaff had plans to grow sugar cane. When he couldn’t secure a quota from the local mill, he started looking around at what else would be viable. He has a friend, who was growing macs in White River, and he suggested Jaff try those. He then cautiously started planting 5 to 10 hectares every year. His knowledge of the crop was elementary and he had been told that you just plant and, a couple years later, start harvesting … sounded simple enough. The fact that macs were a high value, low volume commodity (as opposed to cane which had such high transport costs), was also exportable and non-perishable made them very attractive to Jaff who was looking to change lanes from veg and sugar. So Jaff kept himself busy with potatoes, cabbage, peppers, lettuce and tomatoes and, besides adding a couple additional hectares annually, he left the macs alone.

Jaff’s next big move came in 2002 when he and 5 other farmers leased land in Mozambique. The Zimbabwean situation forced many farmers to start formulating “plan B” and this was Jaff’s motivation for setting up in this neighbouring country. Their chosen crop was macs, the first of which were planted 18 years ago. They now have 300 hectares there. It’s been extremely hard work, in a very different climate but Jaff has enjoyed learning more about how this crop behaves in different circumstances.

Part of the Mozambique farm

While macs were becoming more and more intriguing, the veggies became more challenging … after 20 years of farming veg, Jaff called it and closed that side of the business. All the veg fields were planted to macs.

DIVERSIFICTION

Currently, on this KZN farm, Jaff has 65 hectares of very small trees plus another 230 hectares of which 130 are still pre-producing (less than 3 years old). In Mozambique there are 300 hectares.

He still has about 30 hectares of sugar cane purely because there are some parts of the farm that are out of reach to viable irrigation. As a result, there’s a line above which he just plants cane.

He also in a partnership in a farm, in Richmond … Again, showing his willingness to pioneer, 7 years ago Jaff was a guinea pig in the Golden kiwi market. They planted 20 hectares, hoping to make some easy money. I didn’t know that was possible in agriculture, and it seems it isn’t, at least, not this time. Challenge #1: Jaff was supplied untested varieties, on their own root stock which he then had to replace with properly cultivated plants. Challenge #2: the land had previously been used to grow veg and the soil was riddled with harmful nematodes. Jaff had to invest in replenishing the soil life and health to restore balance. Challenge #3: just as it looked like they were turning a (good) corner, a massive hail storm hit the farm and destroyed all the shade cloth then continued to hail, destroying all the plants. At this point most would have walked away but Jaff has been encouraged by the fruit size on what was left, protected in a few corners, and is looking forward to repairing and trying again. Determination like this should be, and hopefully will be, rewarded!

UNSUSTAINABLY POOR MAC YIELDS

In the 2020 and 2021 seasons Jaff’s macs delivered incredibly low yields. Jaff concedes that this was not unique to his farm and that yields across SA were down. While this might draw us to conclude the cause to be climatic (there were excessively hot spells during flowering in 2021, compounded by very high winds), Jaff is not ruling out management factors contributing to the issue, especially on this farm. In addressing the low productivity of his orchards, he is looking at a number of areas:

- Pruning. The trees that are in production on this farm are old and Jaff admits he hasn’t paid them the attention they required – purely because he didn’t understand the requirements! After engaging a specialist pruning consultant, Jaff has embarked on intensive pruning across the whole farm (see more below, under PRUNING).

- Increasing disease pressure. Jaff suspects that the increased level of various flower fungi may have been exacerbated by orchard density and therefore another consequence of poor/no pruning. But it is also possible that the growing number of macs in the valley will also attract specific pests and diseases.

After 2 years of poor yields, Jaff is grateful that he can (and has) revert back to veg in order to alleviate financial pressure – he is currently doing summer crops of sweetcorn and cabbage, supplying Woolworths and Checkers directly. Just goes to show that, even when a crop looks like it will be enough, one should always consider diversifying, ‘just in case’.

PRUNING

Jaff didn’t do any pruning here in the beginning. He just planted trees and left them, in line with the advice he was given. “Expect a crop in a few years,” was all he was told. The result was a bit of a mess and it’s taken 3 years of intensive work to get closer to where they need to be. “There’s still a lot to do,” frowns Jaff.

Thanks to the South African macadamia industry pioneers we are all now well aware that, for multiple reasons including productivity, disease pressure & insect management, mac trees have to be pruned.

Exactly how to prune is still up for debate but Jaff believes that there is no single correct answer, “If you put 5 great mac farmers in front of a single tree, I bet they’d all chose a different way to prune it – none would be wrong and the outcome will always be better than no pruning at all.”

Jaff employs the services of Alwyn du Preez, whom TropicalBytes interviewed in early 2020 https://www.tropicalbytes.co.za/2020-5-pruning/ and has been following his advice. “The crop is definitely picking up this year,” smiles Jaff, “it was inevitable that the heavy pruning we’ve done would knock the trees back a bit but it looks like we’re certainly on the right track.”

“We needed to reduce the height of the trees without making a straight cut. The best way to do this is to remove the tallest central leader as low down as possible. We have also removed a shoulder at the same time, to allow more light into the tree and maximise spray penetration. The result has been encouraging, despite how difficult it has been to prune so heavily.”

Obviously, this has meant a lot of wood lands up on the floor. Jaff’s team removes the larger pieces, placing them under the trees. The smaller branches are windrowed and mulched. Jaff then moved all the larger logs to a central point, hired a heavy-duty chipper and went to work.

There’s still plenty of catch up to do in pruning, especially in Jaff’s densely planted orchards.

When I asked about skirting Jaff says it’s always his intention to do this better but somehow, they always seem to run out of time. Ideally, he’d lift the lower branches slightly to allow for easier harvesting access.

Jaff’s learnt, the hard way, that it’s best to prune from young and he’s doing that in the new orchards, opting for Alwyn’s traditional Christmas tree shape. Jaff has tried manipulation, using string and plastic forks to force vertical branches over the line to become more horizontal (and therefore bearing) but Alwyn is convincing him that the same thing can be achieved through correct pruning.

These pruners are cutting anything that would obscure the sprayer. These trees are just over 6m tall.

‘Cutting out the shoulders’ well-illustrated.

After the mulcher has been over the pruned branches.

Jaff points out how the lower branches in this overgrown orchard have died back

In this orchard, that was thoroughly pruned last year, there is clear evidence of bearing branches coming into the previously dead spaces that were in complete shadow

PESTS AND DISEASES

“Our unsound is around 1 to 1,5% and it’s made up of a couple sinkers, the odd mould (especially after the recent KZN floods) but the big problem here is MNB (Macadamia Nut Borer),” frowns Jaff, “way bigger than stink bug. I find a couple stink bugs around but nothing to react to.” Jaff’s been trying the least harmful route of control, without success, and after 4 years of increased losses, has had to resort to harsher solutions to deal with MNB. Compounding the problem are the ineffective scouting traps, leaving them blind to actual infestation levels. Jaff’s team has resorted to scouting for eggs to establish the extent of the problem. Not happy with continued use of environmentally harmful chemicals Jaff is employing two more biological approaches in the upcoming season; wasps and fungus. The wasps will deal with the moths in the egg phase of their life-cycle while the fungus is soil-based and will infect the nymphs before they mature into moths. More detail on life-cycles of various macadamia pests can be found here: https://www.tropicalbytes.co.za/2020-7-pest-management/

It didn’t take too long to find the kernel thief in an immature nut that had fallen to the floor with its unwelcome host. Macadamia Nut Borer – larva phase.

Although Jaff pruned heavily last year, there is still a bit of flower fungus, “There are a lot of new diseases coming through macs now. Things we’d never had problems with before that are now manifesting.” He wonders if it is a consequence of the increased density of macs in the area – he estimates that there are close to 1000 hectares in the area now.

Phytophthora is a problem and Jaff paints infected stems reactively. He’s also used to dophosphoric acid in spray programmes when required. Jaff believes it all comes down to soil prep, decent trees (nursery) and soil health – all areas he has, at one stage or another, not kept to the highest level. Jaff is perfectly honest, “Phytophthora is the price you pay for bad farming and I’ve done my fair share; especially neglect in the early years and then stress through over-watering. Also putting people into the orchards with hoes, which damages stems.” Showing what a GREAT farmer he is, Jaff is addressing all of these areas and strictly supervises his orchards’ journey back to good health. Hoes are used carefully, if at all, as Jaff keeps the grass around the trees down to a manageable height whilst still allowing an interrow panel of insect-friendly mayhem. Whilst the ‘mayhem’ is hard (for him) to look at he is hoping it will help address the thrips pressure on the flowers, by providing an alternate source of food for these miniscule pests. And, as a knock on, he’s hoping the decreased thrips damage will decrease the fungus which might be taking hold of the affected flowers.

Every second row in this very young orchard is cut back to provide access to the small trees. The other rows are left to grow taller and provide diversity that will sustain insect life and provide a wind break for the delicate trees.

Jaff points out that they do have husk rot but he doesn’t consider it a problem as it’s a secondary issue initiated by the nut borer damage.

Until he’s found a more sustainable solution, Jaff is spraying twice for thrips; once just before flowering and once again, just after flowering.

As far as theft goes, Jaff only has some subsistence losses (eating nuts in the orchards).

Duiker are a problem on the smaller trees when they rub their horns and debark, effectively killing the tree. Jaff now teepees all young trees to minimise losses.

Protecting the youngsters from duiker looking for horn-sharpening tools.

YIELD

As with the majority of SA mac farmers, a large part of the land is supporting young trees that are either pre-production or only starting to come in. This makes reporting overall tonnes per hectare and inaccurate affair. But Jaff graciously details the roller coaster his production graph resembles; in 2018 he delivered about 150 tonnes. In 2019 this doubled to 300 tonnes – he humbly interjects that this was a good year for everyone in macs – then, in 2020, his crop dropped to 180 tonnes and the red flag was raised. Jaff implemented interventions and 2021 saw a small improvement, up to 220 tonnes. This year, he’s expecting somewhere between 260 and 280 tonnes as more trees come into production. Ultimately, when all the tress are in production, Jaff would like to see this farm produce as much as 800 tonnes.

MISTAKES

Those of you who are TropicalBytes farmers (been interviewed) know that I am just as keen to know what you’ve learnt from your failures as your successes; Jaff doesn’t disappoint; “Ja,” he smirks, “we’ve made lots of mistakes.” The greatest of which he claims was to not do enough land prep before planting. “You only get one shot at this and any short cuts will undoubtedly be regretted,” he warns. In the first plantings, Jaff used a bull dozer but decided to only rip the rows rather than the whole block. He also didn’t ridge and planted using a spacing of 7m x 3m. Remember, this was 18 years ago and we didn’t know what we know now.

Jaff’s oldest trees – 18 year old Beaumonts.

So, let’s take this torrent of ‘mistakes’ and see what Jaff would do differently now:

- Rip and ridge all orchards. He’d loosen the entire orchard floor by ripping and cross-ripping down to 700mm and then create gentle, undulating ridges – like corrugated iron – in all orchards regardless of soil depth. In navigating the journey through mac university, Jaff has created tight, high ridges in some orchards but regrets these too as they make for difficult orchard management – mowing and mulching – and will also be challenging if he ever moves to mechanised harvesting.

This orchard has been struggling so, while Alwyn was there, they opened up around the roots of a particularly yellow looking fellow to see what’s happening below ground. The findings were that the roots are not penetrating the red layer of soil. Jaff says that, in hindsight, this orchard would have been a good one to have ridged so that it had a bit more soil depth. His solution now is to build up the organic matter on the surface so the roots can grow up into that.

You will notice, where the grass is slightly greener, that there is a ‘valley’ here. Jaff will reshape these interows so that the lowest point is midway between the two rows.

Jaff says these ridges are also wrong, they’re too steep on the edges.

This orchard, planted about 6 months ago, shows the shape ridges Jaff believes are best.

This orchard, planted about 6 months ago, shows the shape ridges Jaff believes are best.

Many top farmers say that ridging is unnecessary if there is sufficient soil depth so I pursued this topic with Jaff; he explains that his motivation is based on unpredictable weather patterns. The recent heavy rains in KZN justify his argument. “The land prep you do now is for the next 50+ years and none of us know what’s going to happen in that time. Rather than risk your roots drowning in undrained water, just build a manageable ridge which will allow them to escape at least some of the water.”

“We’ve proven this in a trial we did on the Mozam farm,” continues Jaff, “where we ripped and ridged all the rows in one orchard except for 1 line we didn’t ridge – we just dug holes and planted. The yield between the rows is incomparable and makes me regret that we didn’t ridge the entire farm. We looked carefully at the beautiful, virgin, deep, soils and saw no reason to ridge but the rain pattern has shown us the error in that decision. The land there is vast and flat. The annual rainfall, of 1500mm, is concentrated in just 4 months of the year. When that much water falls it doesn’t matter how deep the soils are, it will sit around the roots and cause trouble.”

- Spacing. Jaff has learnt that this is very farm- and cultivar-specific but has also learnt that, with current commercial cultivars, it should never be as dense as 7m x 3m. His personal default is now 9m x 3,5m. He has tried 8m x 4m but, for him, it’s still not ideal. In deciding what spacing to use, Jaff suggests you are lead by the amount of land you have available, what cultivars you are planting and your management capacity.

It is clear now that 7m x 3m is not ideal.

Because Jaff’s orchards are too dense, Alwyn has suggested he removes every second tree in every second row. So one row would remain untouched and the second row would have every second tree removed. Jaff did a trial in one orchard last year and the yields this year look like this might indeed be a good solution. There is the V2 of this strategy that would entail removing every second row entirely … but that could make a grown mac farmer cry.

This orchard was pruned heavily last year. Every second tree has also been removed from the row on the right. You can see how much lighter this orchard is now.

Jaff bought a tree spade with the intention of saving these 14 yr old trees but the ground was too rocky and the trees too big. He has had better success with this implement, on very young orchards but still doubts the value of the investment.

ORCHARD ESTABLISHMENT

Jaff has not rested any soil before planting macs, opting instead to go from one crop straight into the next. Not all crops are respectful of the new inhabitants though and despite Jaff burning, ripping, cross-ripping, ploughing – three times – and then discing up ridges, some sugar cane still grows through in the new orchards. See pic below. Jaff shakes his head and wonders out loud whether the cane would have grown as well if he had planted it purposely. 🤣 At least it helps as a wind break for the young macs.

If you look very carefully, you’ll see the young macs, well-camouflaged by the determined sugar cane.

The only thing that halts planting in this area is winter which is just too cold – the 2-year-old trees struggle, never mind brand-new ones.

After installing the irrigation, Jaff digs the holes in the ridges and irrigates. The following day 1 litre of organic carbon* is placed in each hole. The trees are placed out into the holes and two women do the planting. One cuts the bag and holds the tree in the hole while the other uses the planting plank to make sure the tree is at the right height. Together they then fill and compact the space around the trees and move the irrigation back in to place. These new orchards then get 6 hours of water. As soon as possible, the trees that need it will be staked. Jaff was advised that young trees should not be staked but he’s doubting this advice and is giving support to more trees.

*Jaff gets this from an old sawmill site that bags and sells the years of sawdust and burnt material on the property.

A planting plank makes sure that the trees are not planted too deep nor too shallow.

Shortly after planting Jaff comes back through the orchard and covers each tree base with a layer of mulch. This is made up of sweetcorn silage, old husks, cane tops – anything he can get his hands on.

For 3 months, there is no further supplementation, remembering that they do have the slow-release fertiliser from the nursery. Alwyn has recently suggested that Jaff cut this 3 month ‘fast’ down to 1 month and apply a special mix he’s formulated, every 4 weeks, from the 4th week.

Recently Jaff has been cutting new trees down to knee height. This is a part of his learnings on pruning. In 2021, when Alwyn visited Jaff, A4s had just been planted on an exposed slope. Alwyn advised that Jaff cut them down to knee height. Finding it too difficult to cut his brand-new orchard down, Jaff hoped for the best but has regretted it ever since as this block is hammered by the wind and Jaff thinks the early ‘manipulation’ would have resulted in trees with a structure far better able to withstand the pressure.

This is the field of wind-battered A4s Jaff feels would fare better had he trimmed them down soon after planting, to stimulate lower, more sturdy structures. This field was recently limed.

So now, he heeds the sage advice and snips lanky youngsters down to about 60cm. From the regrowth, he keeps the central leader and a maximum of 4 side shoots. As those branch out, he cuts anything that grows straight up.

Jaff continues to say that he doesn’t cut ALL the new trees down as some will produce side branches naturally, making no sense to cut these down.

After almost 20 years of buying new trees, Jaff has learnt a thing or two about nurseries; he’s found who not to buy from; anyone unregistered that you haven’t researched or had a recommendation on, and who he will only buy from; Jaff is committed to his current supplier whom he trusts and has a relationship with. Jaff advises that, just like land prep, you only get one crack at this so it is best that you invest time and effort making sure you’re getting the best trees available, even if they’re a little more expensive.

Jaff thinks he’s finished planting now, with his youngest field having gone in in Feb this year. He smiles when I work out that he only has 5 years to wait until they’re all out of ‘nappies’ and in full production.

The future is exciting!

CULTIVARS

The first orchards planted are made up of Beaumont, 816 and 788. Jaff’s not too disappointed with the choice – there are pros and cons to them all.

Beaumont – Jaff says little about this cultivar besides, “It’s great.” So we’ll conclude that this is the favourite child.

A4 – If there’s a rival, I’d say it’s A4 although the trees are not as mature as the Beaumonts so Jaff is not committing beyond saying, “they’re looking good.” Interestingly, Jaff says that Aussies he’s spoken to don’t like A4 even though it’s an Australian cultivar. The reasons they give is that it doesn’t produce well when older, especially if they’ve been hedge pruned – as is the norm in Australia.

788 – “This year these are disappointing, with thick husks and small nuts,” says Jaff. This is not only bad for yield but it is also difficult to dehusk. Jaff thinks that this cultivar might be better suited to the south coast although it does mature first (almost a month before the others) and gives his harvesters something to get going with. Another ‘pro’ is that it always delivers a decent volume, consistently, every year. Jaff is hoping that 842 & 849 will fill this early season slot and allow him to reduce his reliance on 788.

Thick-husked 788.

Jaff mentioned that there are apparently two kinds of 788 and that he has been told that he has both on this farm. I asked Andrew Sheard about them and this was his response; “We aren’t entirely sure about the 2nd 788. The one we grow in KZN is the true 788 which came from the original Hawaii HAES breeding program. The 2nd 788 which we call the ‘Nelspruit 788’ was imported into KZN from a nursery in Nelspruit. FABI will soon be able to conduct DNA ID testing of the cultivars so I’m very keen to have it tested and see if it’s not an existing cultivar which actually has a different cultivar number. The leaves of both look very similar in shape but the Nelspuit one is definitely darker green in colour while the true 788 has a yellow green colour. Yields have always looked better on the Nelspruit one but the few growers who I know have it have never kept it separate so we are unable to compare TKR (total kernel recovery) either. Nut shape is different but I can’t tell you any specific characteristics as I haven’t seen the nuts in over a year.” Mmmm – watch this space as I work on getting more info on the pseudo-788.

816 – Jaff says there’s nothing to touch the quality of this nut but they are particularly susceptible to insect damage. The growing habit also necessitates regular correction through pruning and these orchards tend to be alternate bearing. Of course, they also take a long time – at least 6 years, with very little in yr 6 – to come in to production. They also have a high percentage of stick-tights and, without being able to use ethapon on these trees (it causes extensive leaf drop), it requires additional labour to harvest.

Interestingly, Jaff has noticed how differently this cultivar behaves in Mozam where they flower profusely but don’t set well whereas, on this farm, the flowering is less but the harvest is greater.

Jaff reports that 816 produce a lot of twins.

The most recent plantings are Nelmak 2, A4, A16, 842 & 849 but there’s not a lot to say until they show their fruit. In Mozam the 842s are doing particularly well, as are the 772 (of which I’ve never heard before).

A268 – a relatively new cultivar – Jaff says it’s susceptible to wind damage and botrytis (stem die-back – different to phytophthora) which can be seen in the tree on the far left. He wouldn’t plant it again. You can also see the wider spacing of 9m x 3,5m in this terraced orchard.

When establishing the Mozam farm, they decided to plant every variety they could get their hands on. The result is that there are now a number of orchards that need to be replaced. Rather than top-working, Jaff is opting to remove these trees completely so that he can properly prepare the land before replanting. Daddow, 741 & 660 are cultivars that will be making way for more 842, 772, 816 and Beaumont when farm is fully planted.

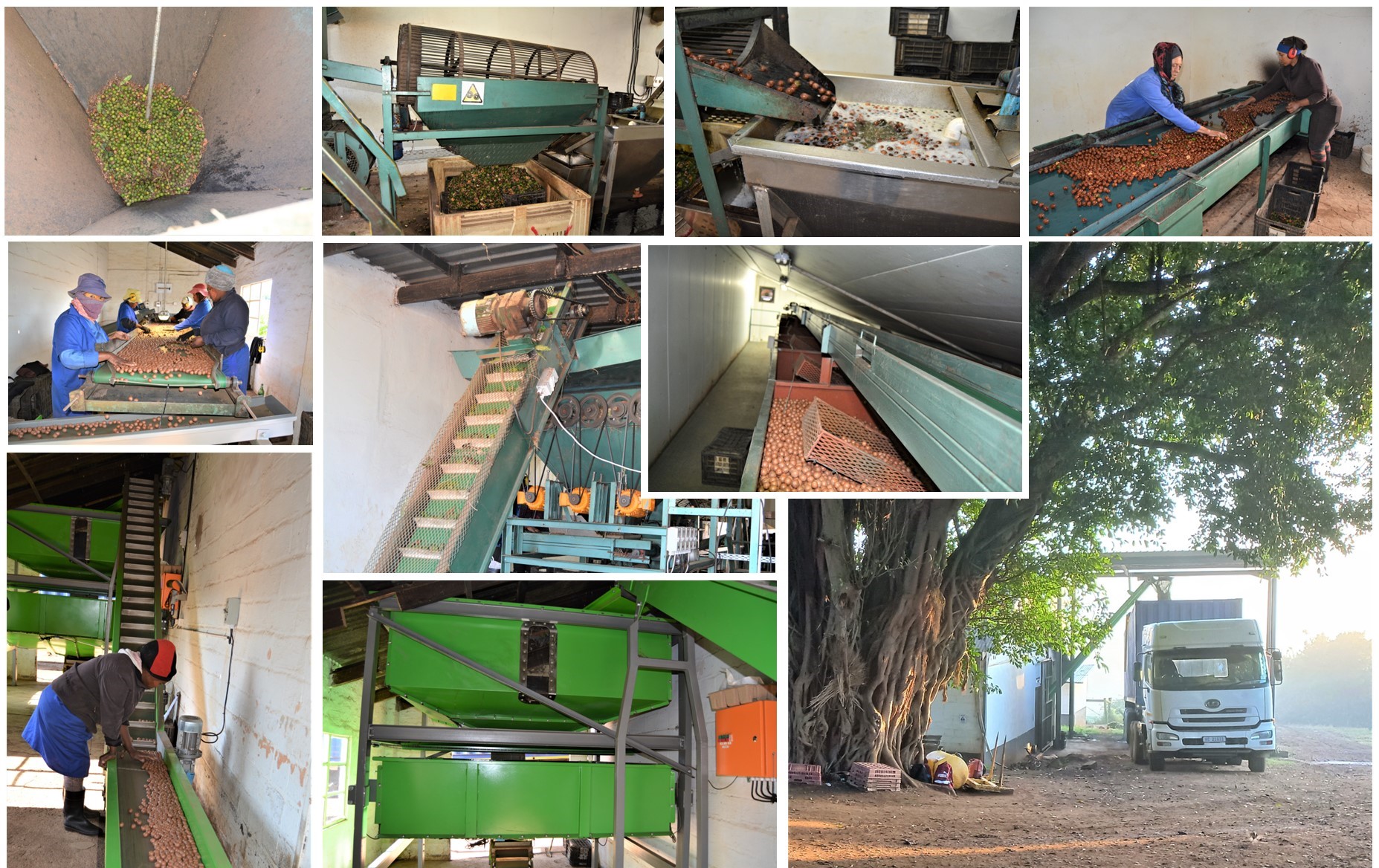

PROCESSING

As in all processing plants the nuts are dehusked and sized. Jaff sends all nuts under 18mm to Wedgewood. Straight after sizing, the nuts go through a bath of sanitiser water and then on to the sorting table and on into the drying bins. These have warmed air circulating through them. Outside air enters the bins after being warmed by a radiator. The water in this radiator has been heated by burning shells (from Jaff’s processor). The warm air is recirculated in the room – as soon as humidity gets too high, extractor fans open and release air to the outside and fresh air is sucked through the radiator.

This boiler system is about 2 years old. Previously, Jaff was using hot air from the ceiling and circulating it through electrical elements in the duct but the heat wasn’t enough to dry the harvest timeously. Eskom’s high rates and unreliable delivery sealed the move over to the radiator system. The heat is set between 30 & 35°C.

Jaff has 26 four-tonne bins. The nuts take between 10 & 12 days to get to below 10%, with the sweet-spot being 8%. In the Mozam plant they have 2 drying sessions because they have been exporting the nuts directly to international customers – for this the nuts have to be below 3%.

As Jaff supplies processor in Mpumalanga, his deliveries are slightly different to most mac farmers; after drying, the nuts are sorted again and then placed into another hopper which weighs them and then releases them into a large, 24-tonne container truck, which makes the trip to Mpumalanga. It takes 2 days to fill this container.

As more of Jaff’s farm comes into productivity, he will increase processing capacity by adding another 6-lane dehusker or two 4-lane units. Storage will also be extended to include an airconditioned shed where nuts can be kept without risk of moisture damage.

Jaff does his best to keep cultivars separate through to delivery, especially 816, as he gets a better price if it’s delivered alone – a full 24-tonne load of 816 is worth the trouble. Because Jaff’s 788 & 816 are side by side in the fields, it takes careful management. When he has enough nuts, Jaff will also deliver A4 separately, as this is another high-value cultivar in terms of quality. Currently the A4s are going with the Beaumonts because the orchards are interplanted.

GLOBAL GAP

Jaff’s main processor works exclusively on the Global Gap system so, as they have been Jaff’s partner since he started, he has come to accept this as standard. Although he’s used to it now, it doesn’t take away from the fact that it is incredibly expensive and a huge amount of work. Jaff’s veg farming is also run on Global Gap standards.

MARGINAL CLIMATE

The main factor that makes this area marginal in terms of macs is the temperatures, which slip outside of the ‘moderate’ zone where macs really thrive. Jaff likens this climate to the one experienced in Nelspruit. The evidence is seen in the thick husks of the 788. Jaff’s challenge is to find a viable solution despite the climatic factors and thereby keep his operation profitable.

Heat is a factor and can get up into the 40’s, usually in Feb, but frost is the main concern. Beaumonts, whom we consider hardy, don’t fare well in frost. Jaff recently lost 5 hectares on one farm when a -4°C cold spell hit. The trees were about 2 yrs old and ‘undressed’ i.e.: no blanket and no spray, as Jaff thought they were old enough to survive inclement weather but also didn’t expect a dip as low as -4°C. Other cultivars hit in the same frost were 816 and A4.

Jaff has since replanted in the same orchard (surrounded by a lazy ox-bow in the river where the air is very still and, clearly, deathly cold) but this time the orchards are better prepared; he’s wrapped the stems in ‘foam’ – the kind you find lining fruit boxes, sprayed the leaves with frost protector and wrapped the canopies in frost-protective blankets. He does this annually, and will carry on until at least year 3. The winter ‘dress up’ is left on for a month or two. The frost blankets can be reused in subsequent years.

These 816s replaced the trees that died after an excessively severe frost. The week prior to my visit saw another hard bout of frost and 15mm of rain yet all these trees, under the protection of both screen duo and frost blankets, have fared well.

Wind can also be a challenge during certain times of year and the A4s, in particular, struggle. Jaff planted casuarina wind breaks but is unsure how much they helped and he’s since removed them. Forage sorghum is what he’s using to screen the current babies but he doesn’t feel this is a viable solution either. “Possibly Napier fodder?” wonders Jaff. This is an area where Jaff feels he could improve.

CROSS POLLINATION

Jaff says he always remembers what an Australian mac farmer said about cross pollination; “Ask my harvesters!” What these mechanised harvester operators reported is that, the closer they got to a cross-pollinator row, the shorter the distance they’d be able to go down the row before they’d have to turn around to off load. In other words, yield increases, the closer the different cultivars are planted.

Jaff has seen that there’s definitely value in cross pollination but he’s unsure how close the cultivars need to be to realise the benefits, considering that mixed orchards are harder to manage. To bolster cross pollination, Jaff planted every 7th row in one Beaumont orchard with A4. The crack out on the Beaumonts in this orchard is 37% and Alwyn attributes this success to the cross cultivar. Although the flowering is well-timed, the A4s mature later so Jaff has to come back to harvest the A4s.

Jaff has also mixed 788 and 816 which he now knows is a pointless combination because their flowering doesn’t sync on this farm. All he’s achieved here is a management nightmare.

The orchard shown here has 5 lines 788 (shorter trees on the left) and 5 lines 816 (tall trees on the right)

Bottom line is that, despite the management challenges, Jaff recommends interplanting and possibly closer than every 7th row. “Just make sure they flower at the same time,” laughs Jaff.

Bees: Jaff appreciates the value bees play and hired in 250 hives last year. This year, he’ll hire 300 hives which is almost 3 per hectare. These will start coming in in August. “Because you need ‘fresh’ bees all the time, they are brought in in batches of 50 hives, over the duration of the flowering season,” explains Jaff, “and I’ve learnt to always make sure the hives are placed in the sun, it gets them up and at it earlier in the morning.” Apparently, just like us, they struggle to get going when it’s cold outside. 😊

I asked Jaff why he doesn’t keep his own bees, given the vast quantity he needs. He explained that there are a few reasons; it’s expensive – about R1000 per hive, vandalism and theft are serious problems. He’s also concerned about the impact spraying would have on this delicate army. “Bees require care and proper management,” says Jaff, “we are getting our environment better equipped to host a diverse range of beneficial insects by planting wild basil and other flowering flora but we won’t go into large-scale bee-keeping without being completely ready.” He is encouraged by the fact that the owner of the hives he has been hiring says that the bees leave Jaff’s orchards healthier than when he dropped them off.

In Jaff’s Kiwi orchards, the bees need to be fed whilst working there – the difference is that in macs the bees collect a lot of pollen whereas, in Kiwis, it’s mainly nectar. For more (fascinating) info on bees, pollen, nectar and honey, enjoy this article: https://www.tropicalbytes.co.za/2021-5-flowers-to-nuts/

HARVEST

Jaff uses ethapon on the 788 (3l per hectare), Beaumonts & A4s (5l per hectare). Even after this, a team of guys, some on an elevated trailer to remove the highest stick-tights, and some on the ground, will move through all the orchards to get the whole harvest onto the ground. Very interestingly, Jaff reports that ethapon doesn’t work well if you spray when it’s cold or just ahead of a cold front – something only a farmer in a marginal area like this would have been able to learn.

A4 (left hand side) has also been sprayed with ethapon. Jaff sprays and harvests the Beaumonts first (right hand row), then comes back to go through the A4s. He reaped about 3 tonnes per hectare off these 6 yr old Beaumonts this year.

Pickers are issued with between 10 and 40 ten-kg bags each, depending on how much harvest is on the ground, and are free to go home when their bags are full (usually around midday). A trailer, with a scale, moves through the orchards and the numbered bags (linked to each harvester) are weighed and the nuts tipped into the trailer. When full, the trailer tips the load into a hopper. The bags go back to shed and the numbers are recounted to double check accuracy on record-keeping.

The weighing system, numbered bags and simple trailer work perfectly.

Jaff knows that, since lowering the speed on the blower that clears the orchards pre-harvest (more info under SOIL HEALTH), he is losing some nuts in the leaves, but it’s in aid of improved root health. They always put a final team of ‘scratchers’ through, with 8 or 10 bags each, to try and minimise the number of germinating nuts through the process in the following season. Jaff is trying to use a side mulcher to chip up everything into smaller pieces so nuts can be seen better but there’s always a small strip left where the irrigation pipes go. Ethapon spray also causes a lot of green leaf drop, making it even more difficult to see the (green husked) nuts.

With all the green leaves, it can be challenging to clearly see all the nuts.

In this picture you can see how the mulched litter in the foreground makes it easier to see fallen nuts but that it remains challenging in the unchipped litter around the irrigation piping running in line with the stems.

Jaff thinks harvesting machines are the future especially early in the season when they are getting under 10 bags per day. The downside of this equipment is that it picks up everything, creating a sorting mission.

IRRIGATION

Most of the average annual rainfall of 550mm to 600mm falls in summer, leaving winter as very dry months (about 10 to 20mm from June to August). Two years ago, they only got 300mm for the whole year. “Without the Umlaas river, there would be no farming here,” says Jaff, “but the river is reliable and supports 1000s of hectares.”

About 5000 registered hectares are irrigated from this dam – Thornlea. There are 3 irrigation dams on the Umlaas River (Thornlea, Mapstone & Baynesfield) Flow meters have been put on all pumps so that extraction can be monitored per farmer. The validation & verification process with department of water affairs started in 2000 and is still ongoing.

All Jaff’s macs are under irrigation; he prefers micro-sprinklers because he can see them working and they’re easier to manage. He’s experienced drip irrigation in veg farming and struggled with the ‘invisible’ blockages, especially as the system ages. In drip’s favour is the fact that it’s easier to fertigate.

The tangible orchard humidity created by micros on a hot summer’s day, coupled with the fact that more of the orchard floor is moistened are factors that make Jaff favour micros. But he is open to experimenting with options and has put drip into a few of the new orchards. They are less than a year old so he can’t say yet whether he has any regrets. He does know that water-soluble fertiliser is more expensive than granular but you use less so it might average out at the end of the day.

In terms of learnings, Jaff highly recommends that you invest in a professional irrigation specialist to design the system; the efficiencies you realise will make up for the initial outlay.

Jaff has one probe per block (av 1,5-hectare blocks), in the orchard floor. A dedicated person takes readings which are then sent to a specialist advisory service every week (twice a week in hotter months). In addition to this, the guy checking the probes also has an auger that he uses to manually check soil moisture. This safety net has proven invaluable and Jaff suggests other farmers implement a similar system. Usually, the moisture reading from the probe and the human align but, every now ‘n again, there’s misalignment and Jaff will go out and double check. They’ve saved a few disasters through this way of doing things.

Jaff has used a tomato-tactic on the macs whereby the soil is purposely dried out a little in winter; this stressed the tomatoes and initiated more profuse flowering in spring. But Alwyn has advised Jaff against doing this with the macs saying it won’t achieve the same result. Jaff now irrigates just enough to keep the macs unstressed through winter.

With all the rain we’ve had in KZN this year, Jaff hasn’t used irrigation since November last year.

SOIL HEALTH & FERTILISING

Jaff advises that all farmers should invest in soil and leaf testing and fix what needs to be fixed. In Mozam, they’ve picked up a substantial shortage of phosphates in the trees, despite there being phosphate in the soil. They’ve added more and have been rewarded with big improvements in tree health. Jaff warns that you have to tread carefully when administering phosphates as phosphate-toxicity can quickly become a problem. This is an issue they wrestle with on the KZN farms that were either veg, cattle or chicken farms previously. It seems that there is no way to remove P from the soil but you can assist in two ways: 1. stop applying any additional P, in whatever form (lots of fertilisers add a bit in to their mix) and 2. help the trees get their roots out of the toxic soil by providing a top layer of nutrient and organic-rich mulch into which they can grow.

Jaff has also been applying an iron-zinc mix into the ‘yellow’ orchards but has been advised to turn his back on these trees as they are planted in what was previously the dairy kraal area and the intense manure has probably changed the soil profile irreversibly. Jaff has not given up yet but had to when it came to another field, alongside the chicken houses where the litter was dumped for years as it’s just become unusable.

Jaff uses granular fertilisers as well as lime and gypsum wherever needed. “The key to success in this area is to get the machines correctly calibrated,” says Jaff, “all fertilisers are different, every field has different requirements; it’s a lot of work. Perhaps that’s where drip is preferable,” he adds.

Jaff does soil tests every second year and leaf tests once or twice a year, in July and again in November. Alwyn looks at these results and gives his recommendations. Jaff values his independent advice saying that everyone should decide who you’re going to trust and go with them otherwise you’ll get overwhelmed and, possibly, misled. Once Jaff has Alwyn’s recommendations he shops around for the best price.

N, P & K are applied granularly and Jaff supplements with foliar sprays based mainly on leaf sample results.

He’s learnt that organic matter makes a big difference to soil health and is always looking around for suitable sources. The latest option is a waste product from the sugar mill; one not previously used on macs so he is currently having it analysed. It generates heat so he’s hopeful it will do the job.

Compost piles of husks and chicken manure

At this point I clarified that mulching is indeed quite different to composting. Mulching is fresh organic matter, used on the top layer of the soil to control weeds, retain moisture and regulate temperature. Compost is used to benefit the soil structure and content by providing essential nutrients. Over time mulch will decompose and become compost.

Jaff has access to a regular supply of chicken litter which he composts for 2 years with mac husks. This is used cautiously, on new trees only, because of the inherently high p levels in many of Jaff’s orchards.

Mulch and micros.

Jaff is investing a lot of effort into enhancing soil health throughout the farms. In addition to supplementing with live cultures, he has planted macadamia mix grasses to cover the interrow soils and add diversity through additional seeds and flowers. “There are now quite a few options when it comes to soil health products and I am doing a couple trials to see whether the higher-priced options are justified,” explains Jaff. He started last year and is judging visually as well as on yield. As these products generally take a little longer to manifest into outcomes, he’s hoping to see some results next year. Jaff’s specific goal is to verify whether using organic supplementation is enough or are the additional products necessary.

Jaff’s focus into soil health is relatively new for him; it’s only in the last 4 years that he’s been adding organic matter back into the soil. All prunings are mulched and put back under the trees.

Jaff is encouraged to see how the surface roots are already using the organic matter he only recently (3 to 4 years) began adding to the orchards.

Based on soil (and root) health, he’s also had to rethink some harvesting practices; they used to use a high-powered blower to blast everything away from under the trees prior to harvest. The taps were turned so high on this equipment that he lost a bit of top soil in the process, exposing some of the fine surface roots. The timing of when Jaff started doing this ‘blasting’ falls in with the decline in yield and, while Jaff knows it isn’t the only cause, he wonders how harmful it was. He has since dropped the revs on this blower considerably and now just aims to move most of the leaves into the interrow without disturbing any soil. At the end of the season when the mulchers come through the orchards, all this ‘litter’ is placed back under the trees with the side-discharge mulcher.

Jaff does use some drenches; mostly fertilisers, and only really on young trees in weak soils. This is something new for him and he’s only been doing it about a year. Other additives supplied in a ‘drench’ method are the natural soil health products.

CHERIO

As mentioned in the opening, Jaff was dreading this interview but I am certain I am not alone in gratitude that he tolerated it – his honesty about mistakes and learnings has made it even more valuable and authentic. As he goes on to build a study group for the area, I hope we all say a heartfelt thank you for how much he continues to selflessly invest in the industry as a whole.

Go well Jaff 24 – spending time in your orchards has been one of my goals for TropicalBytes for a long time – for our readers, it was everything I hoped for!

Thank you!!

Such a healthy happy place.