This is the final Levubu interview of this trip but the first lady-farmer interview EVER!! Although I, myself, would LOVE to be a farmer, I’m really not sure I would cut it … the job can be physically demanding, from a muscle and sheer brute strength point of view. The cultural context of our country also means that women are not always given the stature required to lead a work-force. So, would I be able to meet the incredibly demanding job toe-to-toe? Meeting Jaffess gave me hope …

This was the shortest interview I’ve ever done. It was over in just a few hours. Those of you who have shared with TropicalBytes before know that it can be a l.o.n.g. visit sometimes. So, I wonder what that means for the theories about it being women who talk too much? Or perhaps I just have a very unique Jaffess here, who gets to the point and didn’t allow me to derail her with rabbit holes, the way I usually do! Whatever the reason – this is a nice quick read with a few valuable gems thrown in – enjoy!

| FARM CONTEXT | |

| Date of visit | 14 February 2020 |

| Area | Levubu |

| Soils | Rich reds with a clay content of about 60% |

| Rainfall | 800mm average |

| Altitude | 850 – 900m |

| Temperature range | Av 32°C (lowest 2°C, max 41°C)

Excessive heat damaged the crop this year |

| Varieties | 246, Nelmak 2, Nelmak 26, Beaumont, 788, 814, 842, 849 |

| Hectares under mac | 75

In production: 3ha Nelmak 26, 2ha Nelmak 2, 9ha 246, 30ha Beaumont, 13 ha 788 Pahalla |

| Other crops | Guavas |

Jaffess’ Dad bought this property forty years ago, in 1981. Vast stretches of the 300 hectares are inarable but there was a small, 10-hectare block of macadamias planted. They had not been cared for and he invested a lot of work into opening up the orchard to see what could be made of it. He wanted to plant avocados as well but a soil analyst advised against it, suggesting guavas instead. Besides those, he also planted mielies and sweetpotatoes.

The 50-year-old Nelmak 26s today – they still produce well.

After 14 years of gainful farming, Dad became concerned about his lack of effective diversification should something go wrong in the guava game plan. So, in 1995, he decided to expand the macadamia operation. Although it was not a particularly profitable crop at that time, he knew they grew well on this farm and he was familiar with them.

Jaffess laughs when she discloses that her Dad is a very cautious man, careful with his pennies, and that those 1995 plantings were some of the smallest seedlings ever – they looked like tomato plants in a very open field. She also remembers the weather being incredibly hot and her Dad making shade for the small Beaumonts with remodelled tomato boxes. The local baboons further conspired against this new investment by pulling up the tiny trees whenever they could.

Despite all the odds, and with much time and care, the new mac orchards grew into production. Thank goodness he had made the move when he did because, in the floods of 2000 all the avo trees perished (he had planted some despite the recommendation) and, by 2015, every single one of the guavas fell to guava wilt disease. The macs suddenly went from ‘side act’ to ‘centre stage’.

2011 saw a buoyancy in the mac price and dad was able to extend the orchards, planting Beaumonts on any vacant and arable land the farm offered. Jaffess has since asked her Dad about his preference for Beaumonts and he explains simply; “Beaumonts are like men. All the other ones are like women.” 🤣

Somewhere along the line, 788s were planted. Although they do better than the average 788 in Levubu (because this farm is, on average, slightly cooler than Levubu) they do not do as well as the Beaumonts. Jaffess’ neighbours, who farm in an even cooler climate, further up the mountain, fare better with the 788 cultivar.

Jaffess has added more “women” to the stable in the past three years, including 814, 842 and 849.

Two-year-old orchards – 814, 842 & 849

Jaffess considers this farm to be pretty much “at capacity” with 75 hectares of macadamias and just 2 hectares of white guavas. Guava is now considered a short-term crop because, by 5 years old, they have contracted the wilt and die. Only white guavas seem to be resistant.

Much of the farm is on inarable slopes – this beautiful mountain is part of the farm. In the foreground are 3-year-old Beaumonts with A4 pollinators interspersed.

Dad and daughter have farmed beside each other for 13 years now. Both appear to be very laid-back people who rely on their good soils and natural instinct to improve yield and quality. Right now, they’re happy with production, getting an average of 2,8 to 3 tonnes per hectare (DNIS at processing) from the Integs. The crack out is around 28%. The Beaumonts are proving their position as the favourite child by out-performing the Integs with a 3,5 to 3,8 tonnes per hectare (DNIS at processing) and a 30 to 32% crack out. Jaffess is looking forward to her “girls” improving the game when the ‘eights’ (814, 842, 849) all come in to production.

ORCHARD ESTABLISHMENT

As Jaffess has vast experience in establishing new orchards, we explored what she feels is the right process:

- Jaffess is not fussy about where she sources young tress, choosing to focus instead on whatever is available when she needs it.

- Given the excellent soils here, they just rip the rows (no cross-ripping) down to between 600 & 800mm.

- Add lime or gypsum to correct any unbalances as per soil analysis recommendations.

- Disc the additives in.

- Dig spade size holes that will accommodate the bag size.

- 400g of pelletised chicken litter is thrown in the hole and mixed with some of the soil in the base.

- Plant the tree (level with the ground) and cover up with soil.

- Add about 20 litres water per tree.

- Place a weed barrier cloth around the base.

- Wrap stem protectors around the base.

- Stake the trees for support.

- Leave for 3 months.

Weed stop barrier cloth is placed around the base of each tree – these help with weed control and moisture management.

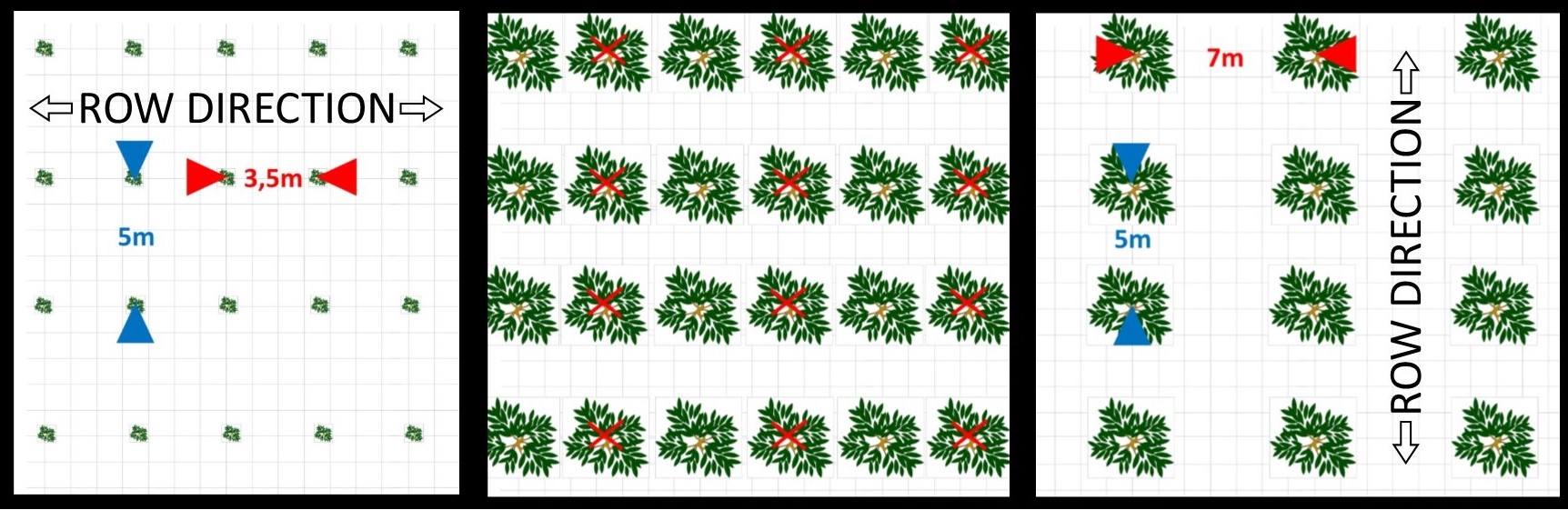

Spacing is managed in an interesting way on this farm; they plant at 5m x 3,5m. Only when crowding becomes an issue – around 10 years, they’ll remove every second tree and change the direction of the rows – explained graphically in the illustration below:

Left: Planting with a spacing of 5m x 3,5m. Centre: remove every alternate tree. Right: change row direction to end up with an orchard that is spaced 5m x 7m.

This methodology has proven to be immensely helpful with early cashflow.

IRRIGATION

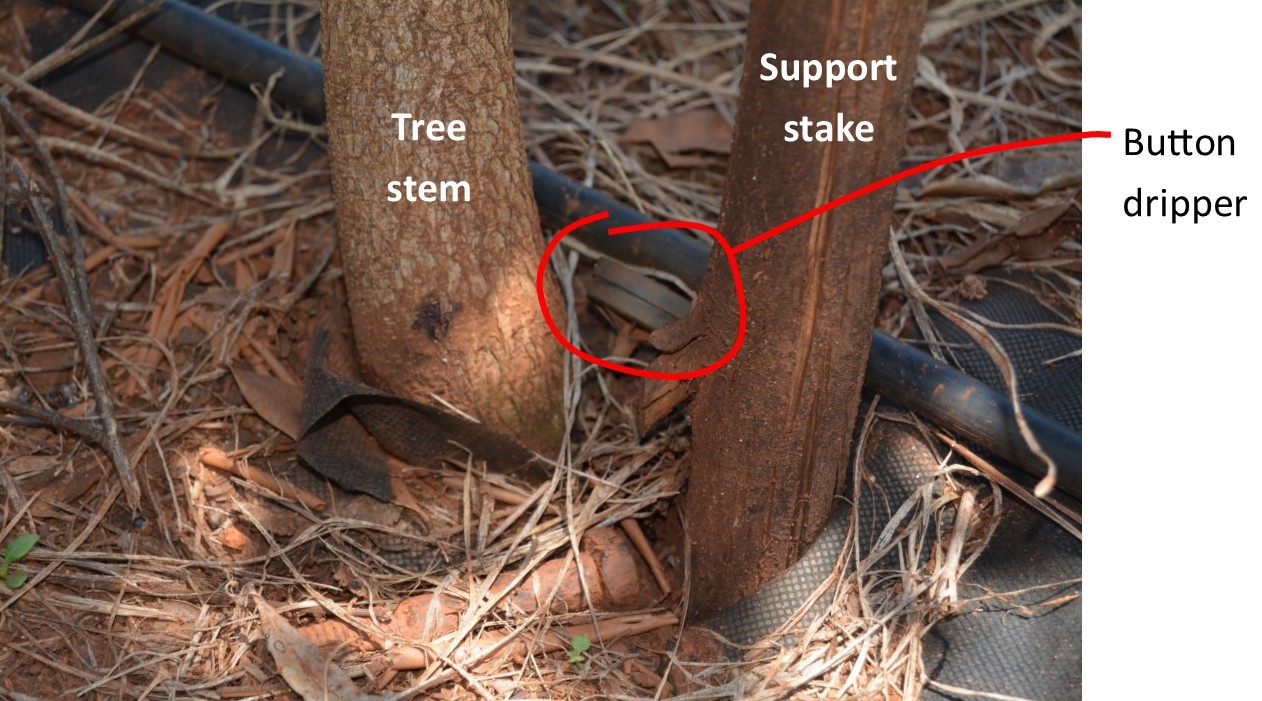

The original old trees have microjets keeping them moist but Jaffess prefers drip irrigation for the new orchards. When the trees are first planted, they have button drippers located at the base of each tree.

Each small tree gets a dripper which delivers about 2 litres per hour. The system in newly established orchards runs for about one hour per day. As the trees grow, the irrigation is run for longer each day.

When the orchard is thinned out and the row direction changed, drip lines are installed with one metre spacing between the one litre per hour drippers. These larger trees get between 2 and 3 hours (depending on the weather) irrigation daily.

Although Jaffess has not noticed any difference in yield or quality between orchards using micros and those using drippers, she values the water savings and the efficient use of water by the drip system.

Although the farm does have a few probes in the ground, they do not dictate the irrigation. Instead they are used to verify suspicions if there are any concerns. Especially in hot, dry conditions – before increasing irrigation, Jaffess will check whether it is as dry as she thinks before extending scheduled irrigation times.

NUTRITION

When the new trees have been in the ground for at least 3 months, Jaffess starts giving 20g of a 2:1:2 fertigation starter with multiple micro-nutrients. Once established, she follows the AgriWhizz programme from the Centre of Excellence. https://centreforexcellence.co.za/

All fertilisers are delivered through the irrigation system, once a week or once every two weeks depending on the programme.

About 60 litres of compost is placed around the base of each mature tree once a year. It is made up of kraal manure, mac husks, wood chips and sawdust from the local sawmill.

All prunings are mulched in the interows. A slasher, used to cut the grass, blows the cuttings and mulch underneath the trees’ canopies.

A nice thick blanket of organic matter preserves the microbial life and moisture around the roots.

Foliar sprays are very seldom used as Jaffess is wary of their expense and unsure of the benefits. She did however, try a calcium spray this year (for 2020 harvest season). Jaffess suspects that their soils tend to hold on to nutrients and believes that calcium is particularly important so she wanted to give the tree the best chance of absorbing this vital nutrient. I followed up with Jaffess, shortly before publishing this story, to see what the results were – she didn’t notice any marked difference and did not apply a calcium spray after the 2020 harvest.

PRUNING

As with all activities on this farm, there is no strict policy: pruning is done to maximise sunlight access and airflow to the inside of the tree. They control the height of the tree and lift skirts just enough to make harvesting a bit easier and minimise sunlight on the root area (about 800mm).

An All-cut hedger used to be used to trim the trees but Jaffess no longer believes that is the best solution and now only uses pole shears and saws to attend to each tree’s individual needs. Every tree is assessed and shaped every year from immediately after harvest until all trees have been seen to, even if that means they go into the flowering season.

DISEASES

For some reason, this farm is fortunate not to struggle with diseases. They had a small amount of Blossom Blight this year but Jaffess holds back on spraying unless more than 20% of the tree is affected.

PESTS

STINK BUGS: Jaffess sheepishly admits that, although she knows it is not sustainable or beneficial to the environment, she does do calendar spraying for stink bugs. For many years she did the scouting herself, with a core team in support. It’s a lot of hard work that didn’t translate into any material benefits for the business. Every year, the processor awards for lowest unsound went to farmers who calendar sprayed. Then, when she fell pregnant and couldn’t scout anymore, she switched to calendar spraying and hasn’t looked back for more than a decade.

Spraying starts in September and continues, every four weeks until the bulk of nuts are out. Jaffess believes that any nuts damaged by insects before September will be dropped in the November dump and there was a lot of logic in her reasoning for this: if a tree is going to adjust its load in November then it will surely drop any damaged nuts before any healthy ones so, by not spraying, she not only saves sprays she also gives the tree an obvious load to dump – a damaged load rather than a healthy one.

The first spray, in September, is a clean up spray; a strong chemical with increased volume – 2500 litres per hectare. Three weeks later, they spray again with a different chemical at the standard volume of 2000 litres per hectare. From there, the 4-week cycle begins, with different chemicals to reduce resistance.

In April they slow down on spraying. The harvesters scout to check on the numbers while they are in the orchards and any spraying is in response to these counts. Once the orchards are free of their produce, scouting and spraying stops.

THRIPS: This is an insect that Jaffess is cautious about spraying, for a few reasons:

- She has done a few observation exercises where she’s infected small nuts with thrips and compared them to ‘clean’ nuts of the same size, at maturity. There was no difference between the mature nuts.

- The chemicals, effective on thrips, are often extremely harmful to bees.

- There are many beneficial thrips that are killed when trying to control the harmful ones.

- Two years ago Jaffess was regularly drenching for thrips but has stopped that and has not seen any impact on the yield or quality in the absence of the drenches in the two years since then.

She believes that thrips can only cause damage on unopened flowers or on the new flush of very young trees.

MOTHS: During November, December and January, Jaffess sprays for Macadamia Nut Borer. They have traps in the orchards so that populations can be monitored and sprays done accordingly. There are no False Coddling Moth issues.

I can tell that Jaffess is not comfortable with the impact their pest management programmes have on the environment – she validates this by explaining that she would opt for biological controls without hesitation, if they were effective but they just can’t risk the losses on this high-value crop otherwise.

HARVESTING

The grand old dames (50-year-old Nelmak 2 and Nelmak 26 orchards) are still producing well. Jaffess keeps accurate harvest records as she is concerned about their age and viability. But, so far, they are keeping up with their younger colleagues and, as long as that is the case, they will remain.

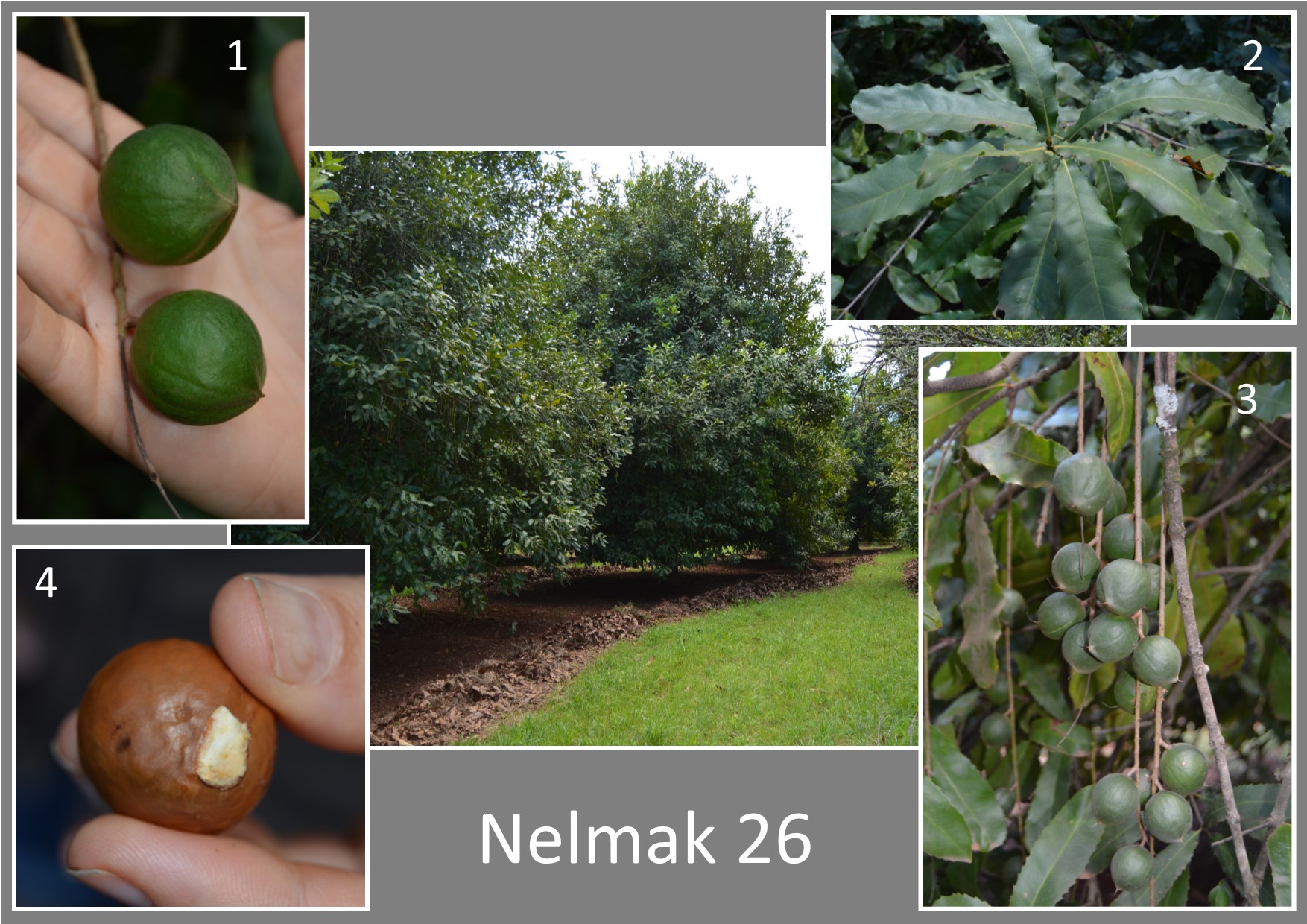

It’s not often we get to see Nelmak 26, especially in the new mac developments so here are some pics showing a few of the distinctive indicators: 1. Large nuts 2. Incredibly spikey leaves – worse than Beaumont) 3. Nuts tend to be one or two per raceme rather than big bunches 4. Shells have a uniquely characteristic divot.

Ethapon is used on the Beaumonts only.

I was surprised to learn that this very old mac operation does not have drying bins. Instead, they collect the nuts, in small crates, dehusk and do a basic sort. The crates are then repacked and left in a well-ventilated room (I suppose this is a drying-room of sorts?) until there is a 5 tonne load ready for delivery. They then transport the nuts, in these crates, to the processor where they are emptied into the receiving hoppers. At this point, the processors are happy to receive the nuts wet but Jaffess knows, as the market supply increases, she will have to invest in some front-line processing equipment for the farm. Despite the lack of extensive sorting and processing, the average unsound score is less than 2%.

Currently Jaffess is splitting her produce between a few processors. The history behind her aversion to allegiance goes back 10 years. The mac price was low, it was early season and Jaffess made a delivery to her regular processor. For this, she received an invoice! The processor had sent her nuts through the factory and the result was that she owed them money! She couldn’t understand why they hadn’t realised, from the sampling, that the load was worthless and thrown the nuts away rather than run them through the factory and invoice her. This experience, during a tough time for their farm, meant that she lost her loyalty and since then she has spread her produce.

I found this interesting as she now has insight into the different sampling and payment results between various processors … she says it’s all much of a muchness. Moisture readings seem to vary quite substantially but crack outs are more uniform. Even if, one year, it looks like one processor is definitely better than another, the next year, it’ll change. In her view, over time, it really doesn’t matter who you process with – every processor is doing what they feel is best for their farmers. Even so, she still prefers to hedge her bets and spread the load.

As I have just reread this story, I appreciate the “shortness” (not sure that’s a word) of it. I hope you do too. Thank you Jaffess, for being brave enough to allow me into your space. For being an inspiration to those of us who would love to farm but have allowed gender (and the lack of a farm 🤣) hold us back. For being real – your relaxed approach to farming is refreshing.

Until next month.