When an International Corporate, who could invest their money anywhere – any country, any industry – chooses macs, in South Africa, it gives the rest of us comfort that we are on the right path. Not that we had any doubt, but it’s nice to know!

Investigating this organisation was interesting – it’s a substantial business, with a team of specialists. As we all sat around the large boardroom table, I was nervous about how I was going to translate what they were doing into something meaningful for our more average size operation. It soon became apparent that, although this enterprise was on an unrelatable scale, the farming operations were totally relevant. The main farmer is a wonderful, warm and very local man who brings with him years of experience and expertise that he is applying in this unique environment as though it was his own farm. He is strongly supported by an expert team so buckle up for a story that features FOUR great JAFFs in one edition!!

I’ve just told you that this is an International Corporate and now I’m going to tell you that this is a family business. Same same but different. 😊 Interest rates in the Netherlands are low. If you want your money to work for you, it needs to go offshore. So, this Dutch family seeks out investment opportunities across the globe. Much of their portfolio is agriculturally-based.

About 40% of the nuts traded internationally go through the Netherlands. The macadamias that find their way into European markets do so through Dutch ports and so this entrepreneurial family identified the growing market with interest. They visited South Africa, as the major supplier into Europe, and decided to invest. Sourcing a suitably sized farm was challenging but eventually they found an 850-hectare property about 20kms east of Louis Trichardt. There were 60 hectares of established macs but plenty of space for the expansive operation they had in mind.

The local team describe the owners as ‘investigators’, saying that they don’t accept the status quo. There is constant encouragement to get outside the box. They also want to be involved in every step of the process, even beyond the scope of this operation – there are no boundaries. This brief insight helped me contextualise the remarkable reach planned for this enterprise.

I was interested (and excited) to know that we are still managing to attract investors on this scale and (nervously) asked about the land claim situation. This farm did have a claim but due diligence was done; the previous owner took it through court and the claim was dismissed. When expropriation of farmland became a topic, the owners had a few concerns but they also explained that our political “challenges” are not unique. They also have agricultural investments in South America that bring similar anxieties.

The transfer on this property went through in September 2016 and they had already assembled the team who would make their investment profitable. As this is South Africa, and full of quality people, it wasn’t difficult to find who they were looking for. The agricultural investment expert who handled the local financing of the farm purchase was brought on-board to continue his bean-counting for the venture.

To head up the agricultural side, they have employed a highly experienced and professional man, local to the area. Rounding off the team is a Computer Scientist-come-Nurseryman (I know, it’s an odd combination but this youthful gentleman is a green-fingered, digital-savvy whizzkid – every farm should have one!) Finally, there is a JAFF who will be rolling the operation into Africa as the business expands. I wish I could share video because this man looks and sounds like he stepped out of a storybook on farming the Wilds of Africa. He’s perfect for the job!

So, this close-knit team work together to deliver on the expectations of the Dutch investors. In the interests of delivering relevance to smaller operations, I focused on the JAFF who was heading up the local operation …

And so Jaff found himself in a most envious role; a blank canvas with limitless potential. Even the mac operation that was already in production had room to improve. I struggled to fully grasp the scale of what is planned but Jaff is unflustered by the magnitude. He comes with a farming heritage, a mechanical background and 9 years of local avo, mac and guava farming experience.

There are 60 hectares of established orchards and approvals for another 400 hectares, although Jaff says it will be closer to 600 hectares because the low-flow drip irrigation they are installing across the board will use far less water than the micro-irrigation system the approvals were based on.

Besides the farming, they have already vertically integrated backwards into a full nursery operation that is feeding their own needs as well as supplying quality trees to outside customers. They will also integrate downstream into processing facilities that will enable them to take full advantage of the lucrative demand for all mac-related processed products. Exciting stuff!!

After so much strategy and business talk, it was a pleasure to come back down to earth – literally – and discuss the practical farming practices that are making this farm so successful. First off, here is a summary of their climatic conditions:

| Altitude | Average of 700m |

| Temperatures | Range from 12 to 43°C. Average – 28 to 32°C |

| Humidity | Average of 60% and below |

| Rainfall | Less than 500mm per year for the last 4 years |

| Soils | All types |

CULTIVARS

The existing 60 hectares range from 12 to 21 years in age and are Beaumonts, Daddow, 788, 814, and 842. The Beaumonts do particularly well and are proving to be a preferred variety because:

- their harvest can be controlled with the use of ethapon. This helps with:

- theft control

- pest management.

- they are producing uncharacteristically large nuts (often over 23mm) for this environment.

- Another perk, especially in a new operation like this one, is the fact that they come in to production early, helping cashflow enormously.

788 are not doing as well as they tend to be alternate bearing and nut size is a problem. As we have heard from other farmers in this area, the hotter, drier conditions are not suitable for 788.

Going forward, Jaff is also going to assess A4 and A16 although they have not been proven on this farm.

I asked about 863 and the superior taste that it is reputed to have. He explains that this “taste” vs “style/visual appearance” is an interesting factor. He prefers the taste of darker ‘discoloured’ nuts to the whiter ‘higher styled’ nuts and believes the market will come to favour these as well. He has a few foliar sprays that he is using to minimise the discolouration and will continue to favour sweeter nuts, even if they are slightly darker. He also spends effort formulating his own foliar feed mixes that will minimise discolouration without compromising taste.

Daddow is a new cultivar for me although it is old for the industry – Jaff explains that it is similar to the 814; a steady bearer with big nuts (20 to 23mm). On this farm, they were farmed dryland but he put irrigation into that block this year and is interested to see how they react. He’s hoping to see their characteristically thick shells thin down.

When considering what else to plant, Jaff will focus on extending the harvest season so late bearing options will be favoured.

Daddow

Daddow

IRRIGATION

I have a fairly unusual view of struggle; to me, it often turns out to be an immense privilege. Our most valuable lessons are learnt through challenging experiences. Struggles build us up so that when opportunities present themselves we have “houding” which enables us to leap, fearless, into the moment and succeed where others wilt.

*for our international readers: houding means character, style or attitude in South African slang.

For local farmers, the 2014/5 drought provided the chance to develop more ‘houding’ than they thought they needed. For Jaff it left him with priceless insight into water management. He saw a disconnect between traditional irrigation and what nature was showing him. Through this devastating drought he was forced to shorten irrigation cycles and wet only the top 10 to 20cm of soil. The fact that the subsequent macadamia harvests were remarkably high, considering the extreme drop in water supply, forced him to reassess irrigation protocols. This was substantiated when there was also a 50% increase in banana yields despite a 50% cut in water supplied.

Jaff is now a firm believer in meeting only the immediate moisture needs of the tree; a “just-in-time” supply.

20 of the existing 60 hectares were dryland when Jaff took over. The other 40 were under a primitive 2 litre per hour drip system. The plan is to convert the entire farm to low-flow drip (0,7 litres per hour) and this is already well underway. This is more complex than it sounds as this type of irrigation necessitates high precision and, with orchards ranging over such a wide scope of maturity, it takes a lot of planning. Additional pump houses are required but, the silver lining is that this method requires 40% less water which will permit expansion to at least 650 hectares. They plan to have all this in the ground by 2023.

There are two irrigation lines in each row, placed about 500mm from the trunk. Drippers are at 1m intervals along each pipe. The trees are planted 4m apart so each tree gets water from about 8 or 9 drippers. Each dripper flows at a rate of 0,7 litres per hour. Depending on precipitation, irrigation runs for 4 hours per day (2 hours in the morning and, if necessary, 2 hours in the afternoon. So each tree will get about 23 litres per day.

There are two irrigation lines in each row, placed about 500mm from the trunk. Drippers are at 1m intervals along each pipe. The trees are planted 4m apart so each tree gets water from about 8 or 9 drippers. Each dripper flows at a rate of 0,7 litres per hour. Depending on precipitation, irrigation runs for 4 hours per day (2 hours in the morning and, if necessary, 2 hours in the afternoon. So each tree will get about 23 litres per day.

There are no probes in any of the orchards at the moment. Instead, in the morning, they go into the orchards with a pole auger and dig 25cm down to check the moisture. As long as the soil is damp to that depth, they are happy that the tree has enough water.

I often hear that a disadvantage of drip irrigation is the pipe blockages but Jaff says these are easily detected and rectified, IF they even happen. There is a dedicated team of guys who check for blockages every day by checking the flow out the end of the pipe but the daily flushes with hydrogen peroxide mean there are very seldom any issues. I wince at the thought of H₂O₂ filtering around the trees’ roots but Jaff assures me that he has done the homework – properly, with a control block – and there is no damage IF you mulch well! He did this by using a special chemical (used to clean hydroponic systems) in one orchard and H₂O₂ in the WELL-MULCHED adjacent orchard, for a year. He then did micro-organism density tests on both fields and there was no difference. As the “micro-organism friendly” option costs 8 times what the H₂O₂ costs, he has decided it’s just not worth it. “The hydrogen peroxide also adds oxygen to the soil, so maybe that helps the micro-life as well,” adds Jaff, “but you HAVE to mulch well,” he reminds us again.

This 20 year old Daddow orchard is now being spoilt with fertigation.

This 20 year old Daddow orchard is now being spoilt with fertigation.

Low-flow drip is starting to make a lot of sense to me and Jaff seems to have learnt a lot in his journey so I dig for a few more pearls …

- Jaff recommends keeping block sizes below 2,2 to 2,5 hectares. Not only do larger blocks make precision management difficult, they also require larger pipes … and those are more expensive.

- Question probes. Although Jaff says that they will eventually install probes, he will be making sure that they report to HIS specifications. His concern is that farmers seldom question the recommendations pre-installed on the systems they buy. He will make sure that settings are based on what HE believes is a healthy moisture content. His advice is simple – make sure the probes are working IN CONJUNCTION with your strategy rather than derailing it with “standard” industry norms.

- Just as the afternoon irrigation is deferred if the ground is too wet, so it is if the environment is too hot. As we explained in the Moisture management article https://www.tropicalbytes.co.za/2020-4-water/ , macadamia trees suspend transpiration when humidity is too low so applying water on these days will not be in line with their strategy of supplying only what the tree needs in the moment. The only exception to this would be if the soil is dry to the point of threatening micro-organism health; in this case, they’ll moisten it for the sake of maintaining a healthy soil.

- Macadamia trees (and probably all plant life) don’t transpire at night – so they don’t recommend irrigating at night.

Since installing irrigation in the previously dryland orchards, the shells and husks have decreased in thickness – which is a relief, considering the expense of this investment!

This pump house, completed in 2018, will cater for 160 hectares. By the time all 600-odd hectares have been planted, there will be 3 like this.

This pump house, completed in 2018, will cater for 160 hectares. By the time all 600-odd hectares have been planted, there will be 3 like this.

GLOBAL GAP

The decision has been taken to go for Global Gap certification throughout the business – from the nursery to final packaging of any processed products, and this ‘pandoras box’ keeps everyone at the top of their game.

In line with Global Gap requirements, there are in-field toilets throughout the farm.

In line with Global Gap requirements, there are in-field toilets throughout the farm.

LAND PREP AND PLANTING

If they’re not specialists yet, by 2023 when all 650-odd hectares are planted up, they certainly will be! So what are Jaff’s insights in this vitally important practice?

- Jaff makes sure that all orchards are planted north-south to maximise sun exposure and penetration.

- As the majority of this farm is being taken from virgin bush to agricultural for the first time, he takes the opportunity to aerate and loosen the soil properly by ripping and cross-ripping to 400mm. This is done with a bulldozer.

- Jaff believes that ridges are unnecessary when farming macs (as opposed to a fussier crop, like avos) except where soil depth is inadequate or drainage is an issue.

- The use of hydrogel has become standard in the planting process, even if irrigation has already been installed. The 3-week grace period (if you can’t get back to the young tree with more water) that this product allows can be life-saving. They mix 1kg hydrogel powder into a 200-litre drum and apply 2 litres per tree when planting in-field.

- As the soil is already loosened, holes of 300mm x 300mm x 400mm deep are dug for the new trees. Half the jug of hydrogel is placed at the bottom of that hole. The tree is planted with a slow release fertiliser and compost and the rest of the hydrogel is placed half way up the hole as it is being filled.

- Spacing is kept to a standard 8m x 4m across all cultivars. Jaff doesn’t subscribe to high density farming as effective spray access is so important with this crop.

- Beaumont blocks are never interplanted with other cultivars because Jaff uses ethapon only on Beaumont. But, when it comes to integs, he is happy to interplant and maximise cross-pollenation benefits. On this scale, he doesn’t see an opportunity to refine management back to a “per cultivar” level.

- The trees are then staked and stem protectors wrapped around the stems. These protectors are cut from tetrapak material (like is used in long-life milk containers) placed with the shiny side facing outwards. This serves to combat sun-burn, cold and herbicide damage. It stays on for about a year and eventually degrades into the soil.

- A good blanket of cut grass is placed around the young tree’s base to mulch and suppress weeds.

- Screen-duo is sprayed to protect the leaves.

- Jaff does NOT trim the young trees at all as he wants the central leader to identify and establish itself. The first time these trees see secateurs is in year three.

These 2-year old trees were supplied by an outside nursery who trimmed the young trees early. You can see how there is now no clear central leader. In about a year Jaff will come through and identify which branch is the strongest and shorten the others so that the ideal upside-down cone shape starts to develop.

These 2-year old trees were supplied by an outside nursery who trimmed the young trees early. You can see how there is now no clear central leader. In about a year Jaff will come through and identify which branch is the strongest and shorten the others so that the ideal upside-down cone shape starts to develop.

The newly planted Beaumonts (from their own nursery), set up for success with their stakes, tetrapak jackets, sunscreen and grass blankets.

The newly planted Beaumonts (from their own nursery), set up for success with their stakes, tetrapak jackets, sunscreen and grass blankets.

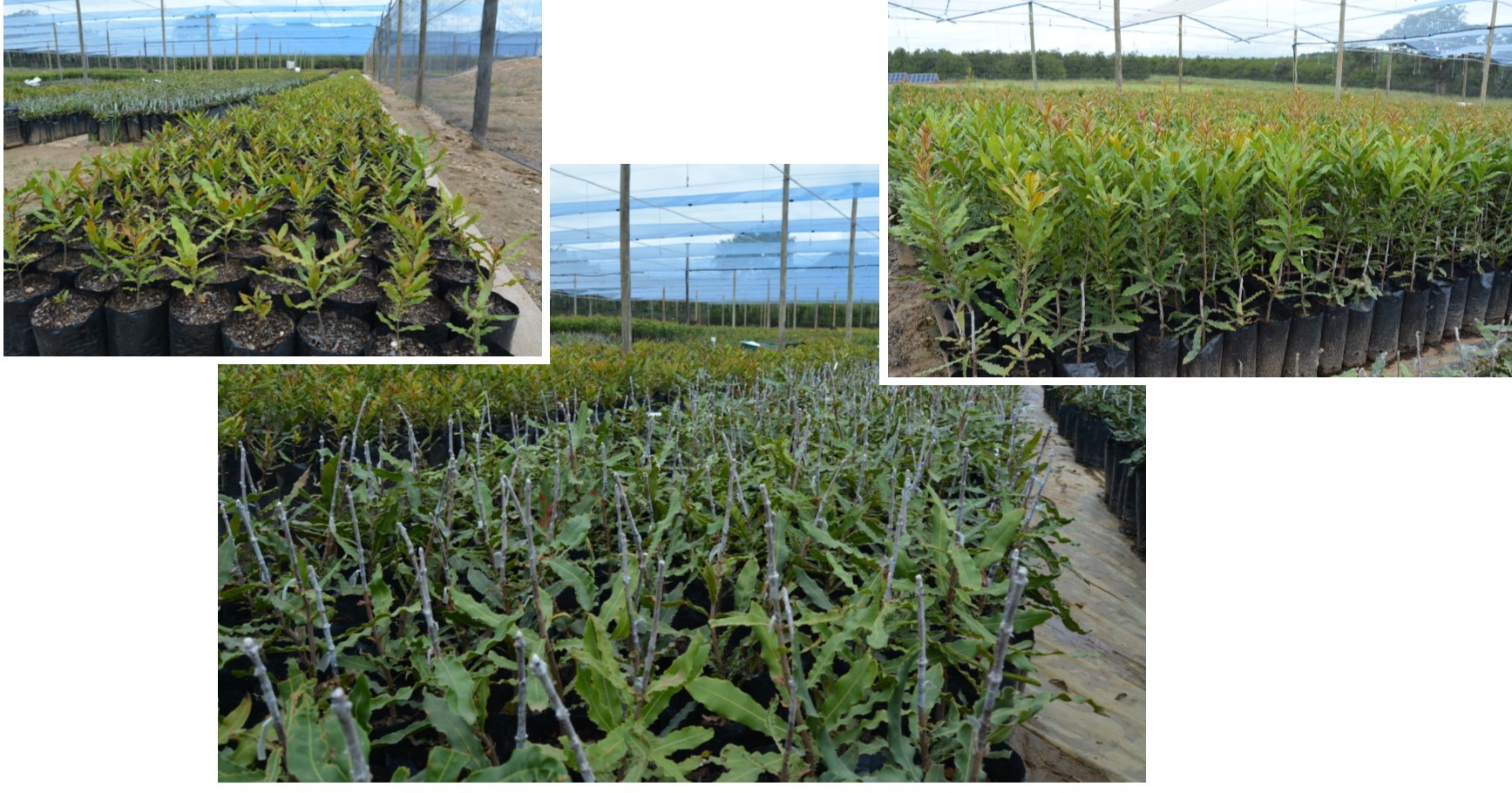

NURSERY

At first sight, it was easy to see the quality of this operation. The new infrastructure certainly helps but there is a solid strength in all the new plants as well.

Everything is grown from seed; there are no cuttings. Budwood is taken from their own orchards by a team that only selects from the highest producers.

Top left: seedlings, centre: newly grafted, right: almost ready to go into hardening off.

Top left: seedlings, centre: newly grafted, right: almost ready to go into hardening off.

There were 3 unique aspects to this nursery that I had not picked up in others:

- The tap roots are not cut. In most other nurseries cutting the main vertical root is standard practice to avoid a number of root issues caused by being in the restricted space of the bag. Here, the plants are ready to go at 14 months with strong tap roots that are not deformed or cut in any way. Jaff believes this gives his trees an advantage.

- Both pH and EC levels of the growing medium has to be right before it is even delivered to the farm. The base is pine bark. Jaff explains that if either alkalinity or electrical conductivity of the growing medium is unbalanced, the young roots can be burnt by the fertilisers. But, when at the correct levels, healthy absorption is facilitated.

- Grafters are incentivised. This is a simple yet highly effective way to hand over success rates to the staff. Each grafter will “own” a batch of plants throughout the 14 months the tree spends in the nursery and is rewarded on her results. She presents her ‘graduates’ with pride as they leave the nursery and receives her reward (usually something highly visible like a big bag of mielie meal) for all her peers to see.

These youngsters are looking remarkably good for only having been in the ground for 3 months (and were 14 months old when leaving the nursery).

FERTILISER

Jaff emphasises that fertiliser for the sake of fertiliser is not advisable – he suggests that you always set a goal and design your fertiliser programme around achieving that.

In this operation, the current goal is to reduce shell thickness and increase nut size in all producing orchards.

Fertigation has allowed Jaff to extend the “just-in-time” approach he uses in water management to feeding the trees as well.

Starting with the new trees, organic slow-release fertiliser is used in the bags. More of the same is given during planting. Six months later, another 200g is applied. When the trees are one year old, the fertigation programme begins.

The annual fertigation programme is tailored to sync with the phenological requirements of the trees. As such, there is a different recipe every month. Precision: 2,2 ha blocks – fertigation specific to each block. Periods overlap so the supplementation will overlap.

Advice:

- Remember that you are farming nuts not leaves. His theory is that, at certain times of the year, when a tree shows a leaf discolouration, farmers will tend to spray magnesium or iron to rectify that. But, then the iron affects the nut colour. So, this year, Jaff resisted the temptation to spray and rode it out. After some rains, the trees became green again. He’s interested to see whether his discolouration comes down. He warns to be careful of agents advising you to treat leaf colour without considering the impact on the nuts. Macs are sensitive to nitrogen at a certain stages in their phenology – too much, poorly timed can cause nut drop. In line with this, Jaff is cutting back on conventional nitrogen applications.

- Treat the core issue rather than the symptoms. On one part of the farm there was a borehole. The previous owner made his kraal there so there are a lot of phosphates in the soil. The trees there now struggle but to continuously spray iron is not solving the problem. And, when you spray, you spray a whole block so even unaffected trees are given iron that they are not even showing symptoms of needing. You need to address the core problem rather than always rectifying what you see as the apparent imbalances.

- Make sure you know what the trees are able to absorb. Conventional soil analyses tell you what nutrients are in the soil but not what is available to the tree. By calling for a water-based analysis you will learn what is available to the tree and what you need to unlock the nutrients that are present but unavailable.

- Keep accurate records and learn from the past. Jaff recommends that you do soil and leaf analyses from the same spots every year so that you are able to see whether last year’s corrections worked. Learn from what you did. Keep accurate records of adjustments made and whether the nutrients were available the next year; in which case you’ll know that what you did worked. If it didn’t, try something else; don’t toxify the soil by continuously adding the shortage rather than unlocking what is already there.

- Test annually and plan two years in advance. Annual testing is better as the tree is on a 12-month cycle. To test every 6 months might skew results in what the tree needs across its full phenology. Jaff reminds us that a mac tree is actually on a 2 year cycle from when it generates the bearing wood to the complete nut. You can also work with this information and support the needs of the tree in this 2 year planning. Building up motherwood that will bear the next year. Support of the vegetative growth is to support the following year’s crop. Consider that the trees are checking their resources and planning for two years ahead. Don’t expect what you are doing to boost root and vegetative growth this year to show results in yield until 2 years down the line. Very important, when trialling different options, is that you don’t write it off too early. The tree is planning 2 years ahead (as it is growing bearing wood).

- Stay ahead of the tree’s needs – correct soils before the trees enter sensitive stages when they will be needing supplementation for specific activities (eg: flowering and nut set)

It’s been a while since I have spoken to anyone doing Brix tests … the sugar farmers do them to establish when the cane is at maximum quality (highest sucrose) so that they time their harvests perfectly. But, I haven’t come across them being done in macs … until now … Jaff does Brix tests on the leaves. If he picks up low sugar levels, he will apply supplementary feeding. These tests are done weekly. When he took over this farm, brix readings were at about 6 and below. Through tight management, they’re now up to 27. If you’re doubting this practice, you’re not alone – when the Dutch shareholders came out last year they struggled to believe in what he was doing. But, they did some sneaky testing on a local orchard that wasn’t producing well and the brix reading was 3! Sometimes, when we cannot SEE something, we doubt it, but all organisms, including us, have ‘sugar lows’ that will affect our overall health if not rectified through better nutrition. Makes sense when you look at it that way …

A brix test kit

A brix test kit

I pestered Jaff for more detail on exactly what he’s applying to adjust sugar levels, but he’s a bit like the family baker who holds the exact recipe close to their chest. I did manage to extract some interesting titbits though:

– In flowering, (July to October) the trees need zinc and boron in the soil and on the flowers. Jaff shared that the trees also need a micronutrient that I hadn’t heard about before – molybdenum. This helps with nut set. Apparently, this is commonly used on sunflowers; if it isn’t then the seeds end up being hollow. Jaff decided to try it on the macs … I did a bit of research: Molybdenum is an essential micronutrient required for nitrogen metabolism. The enzyme of root nodule bacteria as well as nitrogen assimilation plant enzymes require molybdenum. Jaff is happy that he’s on to something that is making a difference to the yields through increased nut size.

– In nut set (mid Sept to mid Nov) – nitrogen, calcium, magnesium, potassium and phosphates are important.

– Flower development and nut development – overlaps. Sometimes all three phases (inc nut set) are in one month.

– In April and May, fertiliser is cut right back as the trees immediate needs diminish.

Generally, Jaff only adjusts the fertigation recipe once a month but will make an exception for anomalies like heavier than expected flowering or unexpected weather patterns or low sugar levels!

The pump room (and fertigation control centre) has four tanks, each with its own recipe (NPK and some micro-elements like mag, sulphur, zinc etc) and they select what they need from each tank. Many of the micro-supplements are done through foliar sprays.

FOLIAR SPRAYS

On this farm foliar sprays are applied 4 times per year. Every spray has a clear goal:

- Fruit set

- Cell division (to support a bigger nut)

- Two sprays support oil accumulation

Jaff gives some basic but invaluable advice against what he has seen too many farmers do: buffering water incorrectly. “You have to be careful about when you buffer the water to get to the right ph. The label on the foliar feed will specify the ph of water to mix with the feed. You need to add the buffer to the plain water (thereby adjusting the ph first) before adding the foliar feed. Some farmers will add feed to the water and then try to adjust ph with a buffer. This will result in an ineffective (and possibly harmful) spray as the chemical formulation will be unbalanced. This logic applies to all sprays. Know what your guys are doing – check up, even if you think they’re doing it right.”

He had some priceless advice on a practice that I hear a lot of farmers doing, sometimes under guidance from their chemical reps: spraying chemicals (pesticides etc) and fertilisers together. As Jaff has just explained, every solution; chemical or fertiliser, needs to be applied at the correct pH to be fully effective (and not harmful). Mixing different chemicals into one application will most certainly alter pH levels. To illustrate this, Jaff reminds us of how, as humans, our health is affected by the pH of the water we drink and by the pH environment within our stomachs – and that it is exactly the same with plants.

The mobility of nutrients is determined by substrate pH (water). Especially affected are those nutrients that plants require in small quantities, called micronutrients or trace elements. When the pH is too low, the micronutrients become more mobile and are absorbed in excess of what the plant needs, resulting in this potential for toxicities. When the pH is too high, the micronutrients are less mobile and the plant cannot absorb enough, which results in deficiencies.

COMPOST

Composting is part of the programme Jaff follows to farm WITH nature. The previous owner used glyphosates extensively with the result that all orchards were grassless so Jaff has been trying to recover a balance since he took over.

Compost piles are built from wood chips, kraal manure and mac husks. They are left to decompose for about 2 years. Jaff then tests the carbon ratios and makes sure that the soil is healthy with the right bacteria and earthworms. Whenever compost is available it is placed around the base of the trees.

PRUNING

Jaff believes that excellent pruning is the crux of successful macadamia farming. So, what is ‘excellence’ when it comes to pruning?

Here are Jaff’s fundamentals:

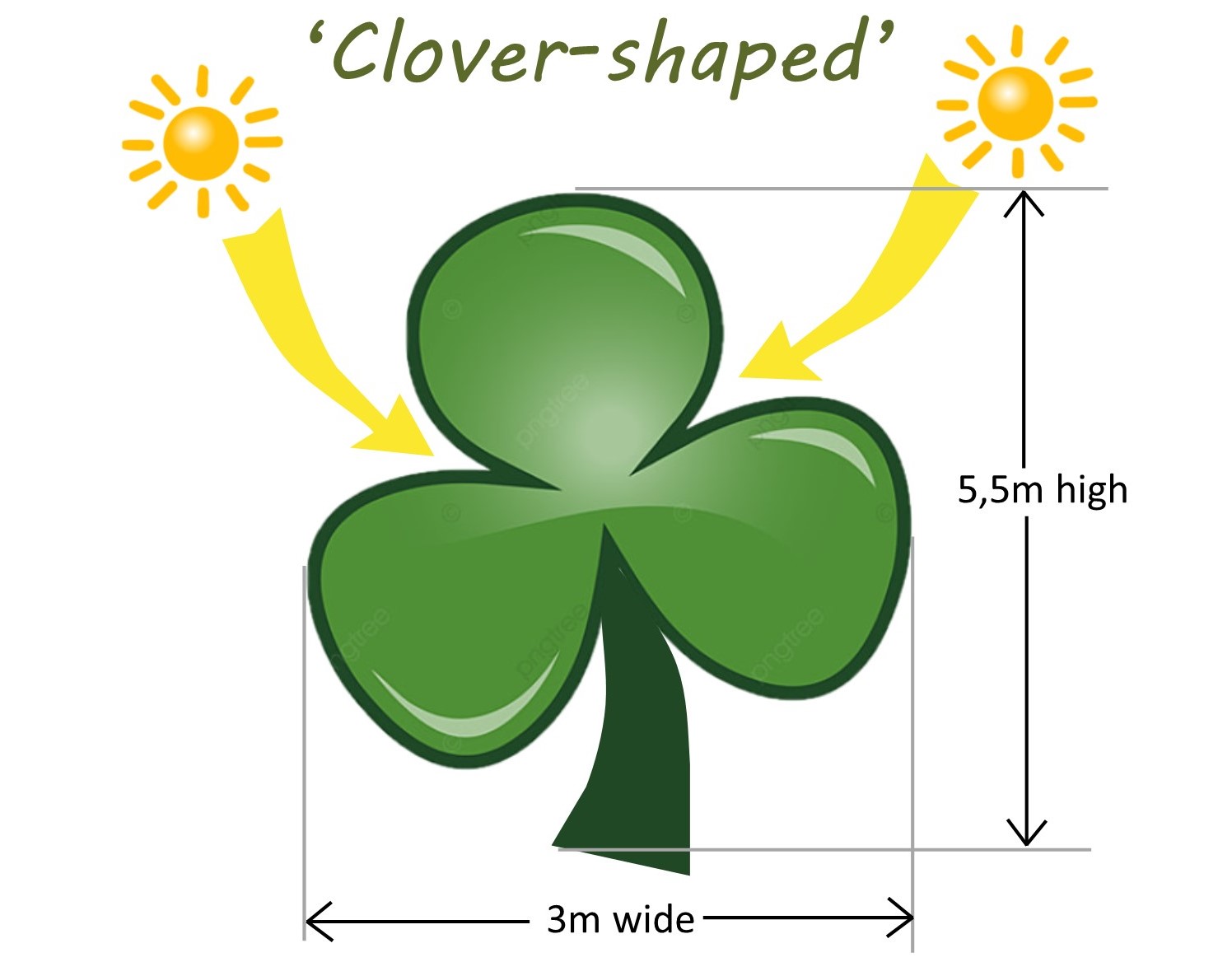

- Create a clover-shaped tree with large windows to let in plenty of sunlight. More on this below.

- Keep the trees short so that spray access is uncompromised.

- Immediately after harvest, prune and sanitise so that the flowers come in as soon as possible, with no damage.

- Take note of the information your trees are giving you during the harvest – if there are non-bearing branches, remove them to make way for new, bearing wood.

- Don’t stop pruning; make it a year-long activity. Good pruning is a constant exercise of removing non-bearing wood to make way for bearing wood. Jaff’s irrigation team has been trained to manage any water shoots they see while checking the irrigation systems.

- Avoid mechanical pruning. In Levubu, where mechanical pruning has been a popular option, Jaff was one of the first to practice hand-pruning.

- Unless you want regrowth in exactly the same place that you cut a branch out, cut right back to the trunk.

Jaff has built a fleet of specialised pruning trailers to help them achieve the clover shape he wants.

The trailer spans the width of the interrow so both sides are worked simultaneously. There are 5 labourers per trailer: two on the top level, trimming height to 5,5m, two on the lower level, making sure that there are adequate windows and one on the ground to manage the lower branches on both sides. Each person has a pole saw.

The trailer spans the width of the interrow so both sides are worked simultaneously. There are 5 labourers per trailer: two on the top level, trimming height to 5,5m, two on the lower level, making sure that there are adequate windows and one on the ground to manage the lower branches on both sides. Each person has a pole saw.

Pruning was a neglected task on this farm prior to Jaff’s arrival and it took him 2 years to get it back into shape. It also cost a third of the harvest this year but he believes that there was no option and that they will (literally) reap the rewards in years to come.

Another pruning practice that I hadn’t heard much about previously was the focus on opening between the trees in the rows. Traditionally, farmers who hand prune will look at a row and open windows in from the sides. Jaff first opens windows between the trees (so that they are not growing into each other) and, when that is done, he will open windows from the interrow side.

Jaff reminds us that only horizontal branches bear fruit. Vertical branches won’t. If you can manipulate a vertical branch to a horizontal position it will become productive. This is feasible in smaller scale operations.

Although it might be obvious to consider the tree from above (where the sunlight comes from) it was something I have not done before (blush) so perhaps there are one or two others of you who may benefit from this somewhat remedial tip:

This is a mac tree, as seen from a bird’s eye-view. The red branches are the lower ones. The yellow ones are higher up. All good except where the blue arrow shows that the higher branch obscures the lower one. In this case, Jaff will assess which branch needs to be removed but both cannot stay.

This is a mac tree, as seen from a bird’s eye-view. The red branches are the lower ones. The yellow ones are higher up. All good except where the blue arrow shows that the higher branch obscures the lower one. In this case, Jaff will assess which branch needs to be removed but both cannot stay.

Jaff does not do any skirting except when the branches lie on the ground. I wondered how this would play out when mechanical harvesters are brought in. But Jaff explains that is why he keeps the tree width under 3m. The operator can easily push the equipment under the branches, from the interrow.

Lower skirts provide an ideal environment for healthy, moist mulch and vigorous feeder roots. Note the beneficial white fungus.

Lower skirts provide an ideal environment for healthy, moist mulch and vigorous feeder roots. Note the beneficial white fungus.

Although Beaumonts are known as the toughies of the macadamia squad, Jaff has learnt that they don’t appreciate a heavy pruning. When he was actively getting the orchards back into shape, the integs bounced back far quicker than the tough old Beaumonts.

This is a great picture showing both pruned (with mulched prunings) and unpruned rows, with the team, in action.

This is a great picture showing both pruned (with mulched prunings) and unpruned rows, with the team, in action.

HARVESTING

Jaff uses ethapon cautiously as he believes that there is a detrimental effect (nuts will gradually get smaller) to long term use. Only the Beaumonts are sprayed and Jaff over-dilutes the solution every second year. If the orchards are in good shape (for spray penetration) then the diluted spray and a little manual help gets the job done.

For the other cultivars, the fallen nuts are picked up every second day throughout the harvest season.

Jaff carefully moves the majority of the surface mulch by pushing it towards the tree trunks rather than away. He doesn’t believe he loses too many nuts in the mulch as the husks of recently fallen nuts are green and stand out against the dark brown mulch. He believes that the consequences of moving the protective mulch out into the interow, away from the root zone, will be far more damaging than the cost of a few lost nuts.

LABOUR

Most farmers pay per crate or a bonus for crates over a certain number. In 2017, Jaff decided to test his theory that this might not be the most productive method. He paid one team a “rate per crate” and the other; a set rate per day. As he suspected, the team working for a set number of hours per day rather then for a set number of crates, was the more cost-effective option. It is probably because they were focused on picking up nuts without the distraction of constantly tallying their remuneration. He still weighs each person’s harvest though, to make sure that no one is slacking. From these records, he also hands out weekly ‘prizes’ to the most prolific harvesters. “You’d be amazed at how hard they push to compete for this simple reward (bags of mielie meal) and how much healthy competition it generates,” laughs Jaff.

A similar incentive is offered in the nursery; grafters are rewarded for over 95% success rate, after 8 months. There are qualifying criteria in terms of quantity, averaging about 100 trees per day. Jaff knows this works as the staff will come to him and proudly present their work when they know they have qualified for the reward.

Owing to the success of this healthy reward system, Jaff has extended it to all divisions – the dehusking store for low unsound rates, spray teams – also for seasonal low unsound.

The 814 harvest is estimated at 3,5 to 3,8 t/ha DIS (4%).

The 814 harvest is estimated at 3,5 to 3,8 t/ha DIS (4%).

Beaumonts gave 6,3 t/ha DIS (4%) last year.

Beaumonts gave 6,3 t/ha DIS (4%) last year.

ADVICE ON AUTOMATION

Because of the scale this business is planning to get to, many of the operations will have to be mechanised but Jaff has some advice on automating: “Don’t jump into automation at the cost of losing touch with your trees. Software can be expensive and puts a ‘filter’ between you and the farm. Keep the human-tree interface, supported by technology. Precision is important and that can be compromised by too much equipment. Precision is not the same as technology/automation.”

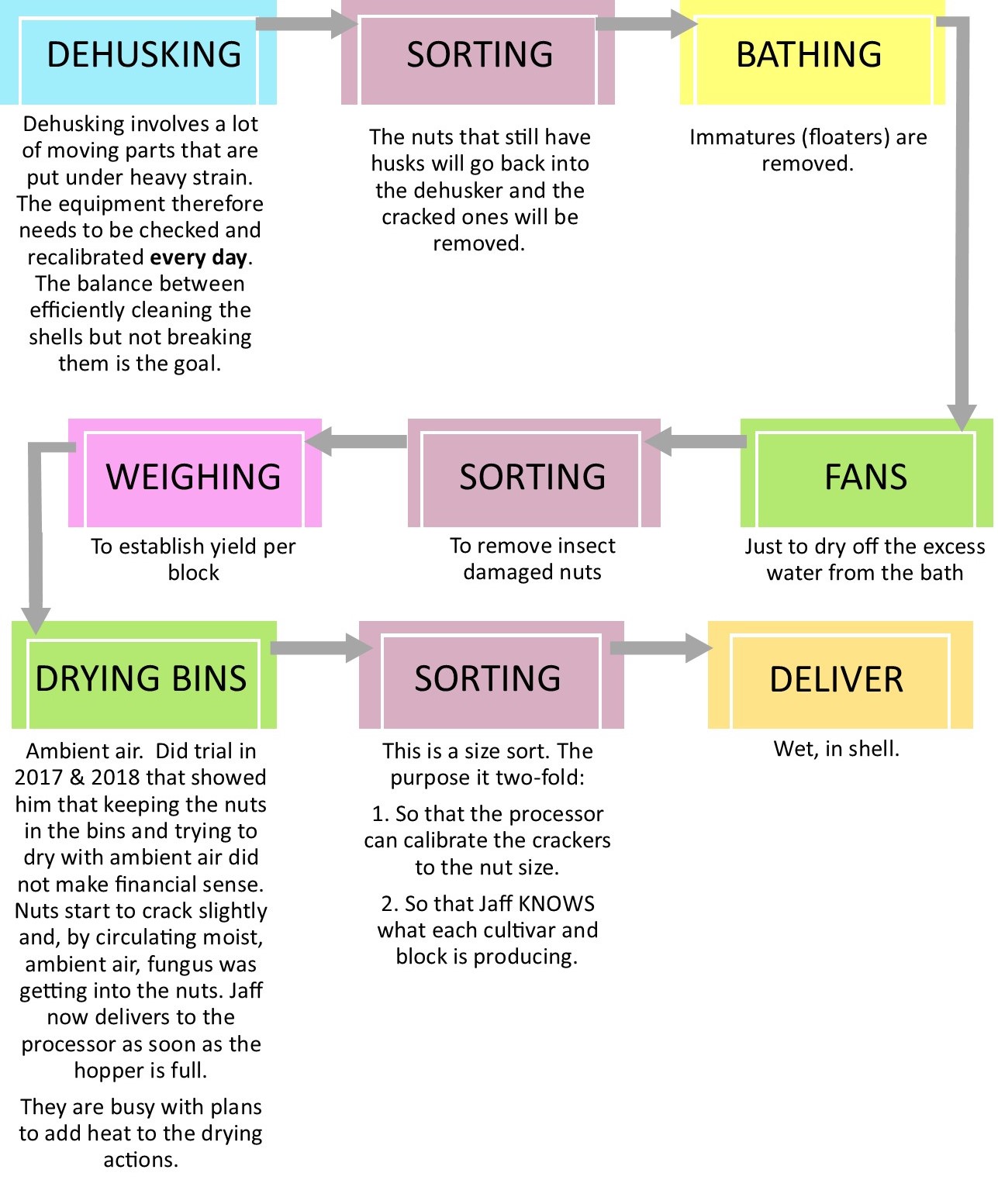

PROCESSING

The diagram details the process but I’d like to highlight the third sort, where the nuts are mechanically sized into 18mm and under, 18 to 20mm, 20 to 23mm and over 23mm. The results of this sort are invaluable. Right now, he is not only using it to assess nutrition programmes but also to advise cultivar choice for the planned plantings. Through this he was able to clarify that his Beaumonts are producing in the 20 to 23mm category. Industry norms are 18 to 20mm for this particular cultivar. By running the numbers (yield, style, prices) he saw that the Beaumont orchards were actually out-performing the traditionally “better” varieties.

I was equally impressed by the other reason Jaff invests effort into this sizing step which is to improve his style spread at the processor. As you can imagine, cracking machines need to be calibrated according to nut size but processors receive “mixed bags” from their suppliers and usually have to run a load regardless of the spread of nut sizes. The machines are set to an average nut size meaning that unnecessary damage may occur on nuts that fall outside of that ‘average’, thereby lowering the style of that nut from a whole to a halves or from a halves to brokens. Jaff has found that his style spread moved up when he started delivering ‘sized’ nuts.

INTEROW MANAGEMENT

Whilst Jaff is very cautious about what he does with the interows, he does believe in doing something. These are his suggestions:

- Whenever possible, try to plant indigenous flora so that local fauna and insect life is supported.

- Jaff has used a mix of sweet and sour grasses as well as clover and lucerne (to help supplement nitrogen) in the past.

- He is currently investigating mustard as he understands that it helps deal with eelworm and other harmful nematodes.

- Midmar grass grows fast, yields a lot of dry matter and is therefore good for mulching.

- Use the area to stimulate cashflow:

- Jaff has planted bananas when the macs are small

- He has also allowed the local communities to plant subsistence or small cash crops – this is on a trial basis, with select, small local farmers.

Jaff has managed to reintroduce indigenous grasses to the previously bare interows. Under the trees has been sprayed with paraquat ahead of the harvest.

Jaff has managed to reintroduce indigenous grasses to the previously bare interows. Under the trees has been sprayed with paraquat ahead of the harvest.

What ever you decide to do with the “interow opportunity”, make sure you fully understand the impact it has on the macs e.g.: maize will drain the phosphates from the soil, and anything you spray in the middle will affect the whole environment. On this point, Jaff mentions that he suspects that the current guava-wilting disease that is ravaging the crop in this area may actually be initiated by eelworm which weakens roots and increases susceptibility to the wilting disease. By interplanting guavas with macs, is there not a risk of exposing this valuable crop to the same pandemic? Jaff feels the risks is too high and would avoid that option completely.

There is no glyphosate used on this farm at all. Paraquat is used to remove the chlorophyll from the growth under the trees just prior to harvest so that the green nuts are more easily visible.

This may be useless information for most but I was enlightened: moss only grows on ‘dead’ soil crust (that’s why we always see it on paving) so, if you see moss in your orchards, it’s time to break up that soil so that air and nutrients can penetrate through the top layer.

This may be useless information for most but I was enlightened: moss only grows on ‘dead’ soil crust (that’s why we always see it on paving) so, if you see moss in your orchards, it’s time to break up that soil so that air and nutrients can penetrate through the top layer.

INSECT MANAGEMENT

This was a fairly short conversation as Jaff believes that correct pruning is the foundation of a good pest management programme. Beyond that, it comes down to dealing with what your specific issues are, in an environmentally sound way. Jaff is bordered by farms that do not spray for any insects – which he believes adds a complexity to his challenges. He has chosen an integrated approach to pest management which increases the costs dramatically; besides wages, chemicals are the next biggest cost. Right now, thrips and Macadamia Nut Borer (MNB) are the biggest challenges. Although Jaff does scout, he also follows a set spray programme with regard to the stink bugs. The scouting is just to check up on efficacy. He recommends that a different area be scouted every time – while this seemed obvious to me, Jaff explained that many farmers scout the same few trees every time.

There was a good array of butterflies in the orchards – to me that indicated a fairly healthy ecology.

There was a good array of butterflies in the orchards – to me that indicated a fairly healthy ecology.

- Stinkbugs – Initially Jaff was scouting to determine when to spray but ended up consistently spraying every 21 days so he now sprays according to that programme (from December to April, for late stink bug) and scouts just to stay informed about what is in the orchards and what the programme is affecting. He is happy to report an unsound kernel record of just 0,1%. He will always avoid spraying the same pesticide twice in a year and therefore employs a wide range of chemicals. When it comes to early stink bugs, he drenches with Kohinor in August and this effectively deals with the early stink bug.

- MNB – in 2017 Jaff tried to disrupt the mating patterns by placing a pheromone in the orchards but, when the packhouse showed no change in the damage compared to the previous year, he changed tack and tried the “attract and infect” method in 2018. Pheromones attract the moths into a trap where they move through a chamber loaded with a deadly fungus (metarhizium.) This time, the packhouse reported a substantial drop in damage and so Jaff continues with this way of dealing with MNB. It costs R47 000 per month (for 9 months) for 60 hectares and is biologically-friendly.

- Thrips – now THIS is a challenge! If levels are high while the flowers are full, he sprays every 4 days in an effort to break the life-cycle but hot weather makes it very difficult. Jaff groans that this year was so bad, you could see the thrips-clouds in the air. As a result, all the nuts are brown and while some believe that this does not affect nut size, Jaff is concerned.

- Bees: On the flip-side, beneficial insects are nurtured. This operation actively encourages bee populations and will even turn it into a side-line business shortly. The plan is to have 4 beehives per hectare and they are busy with the construction of concrete hives. To support this, and other beneficials, there are no systemic chemicals used anywhere on the farm.

WILDLIFE MANAGEMENT

There is a healthy array of wildlife in the area that Jaff is encouraging. They have built a series of waterholes to support the populations which include red and grey duiker, waterbuck, bush buck, blesbok, porcupines, bush pigs, civet cats, owls, and an indigenous white-tailed rat that is on the endangered species list.

Waterholes and grazing areas interspersed throughout the orchards

Waterholes and grazing areas interspersed throughout the orchards

- Monkeys are the biggest concern when it comes to co-habitation with nature. There are four men whose sole job it is to chase monkeys – they do this with large whips that sound like gunfire when cracked!

That puff of white dust you see there was a hella-loud crack and a very efficient monkey deterrent.

That puff of white dust you see there was a hella-loud crack and a very efficient monkey deterrent.

- Bushbuck annihilated a number of young trees this year because of the drought. Jaff is avoiding fencing as it defeats his wildlife integration programme and opted to net the young trees instead. When there is enough grass, the buck damage is less of a concern.

- Porcupines can be a menace when they chew through the irrigation piping and so Jaff sets traps so that they can be caught and released on the other side of the farm.

DISEASES

Phytophtera damage

Most disease issues in the established orchards have been caused by previous poor management. Some orchards had 2 litre per hour drippers placed right up against the tree stems. The mechanical damage caused by the water flow as well as the excessive stagnant water and poor soils were the perfect recipe for phytophtera. Jaff explains that there are a few ways to deal with these issues and his plan is:

- Reconfiguring the irrigation – as mentioned, they now drip 0,7l per hour and the drippers are 500mm away from the tree trunks.

- Mulching – this will give the sensitive feeder roots somewhere to live, in well-aerated environment that nurtures healthy fungi.

Already, these two changes have helped tremendously with the eradication of this disease but,

- If pushed Jaff will cover all the stems with a concoction that he has previously used on avos; a mix of a fungicide, wood-glue and tree paint.

- There is also the option to drench with a fungicide through the drip irrigation system.

But Jaff explains that diseases can be managed fairly easily if basic principles are kept:

- prune well so that the orchards are well-aerated and any sprays are more effective because they penetrate to where they are needed.

- Mulch well to keep the roots up; out of potentially water-logged soils.

- Irrigate only what the tree needs, when it needs it.

INDUSTRY OUTLOOK

Farmers are, by nature, optimists. Even the cautious ones are buoyant, and bring solutions for any concerns. Such is this Jaff: although he feels that it is “easy money” right now, it won’t always be so. As supply is increasing, the consumer market is becoming more discerning. This is evident in more regularly specified colour preferences, for example. So, what can we do to heed Jaff’s warnings?

- Don’t wait until demand for your “any size, any colour, any style” produce starts to lose value – start laying the foundations to improve your product, now.

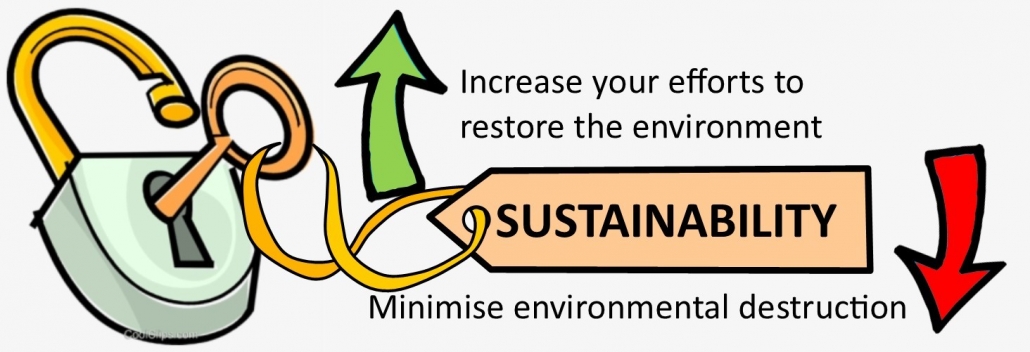

- Carefully consider the SUSTAINABILITY* of every operation on the farm. If you are employing short term solutions to long term problems, start thinking about how you can rectify that because when the going gets tough (supply starts catching up with demand and the inevitable price ceiling gets heavy) only forward-thinkers will survive.

*Sustainability is one of those over-used words that we may be becoming desensitised to. And yes, I am guilty of over-using it because I am so passionate about it. So, allow me to define what it is we are promoting:

Profit is the difference between what we put in and what we get out. To keep something sustainable, in a financial sense, we need to maximise income and minimise costs.

Income is determined by the market forces of supply and demand – we are less able to manipulate this than we are costs.

Controlling costs is key to sustainable profitability. In the farming world, the biggest costs are around human resources and environment control (weeds, pests, water, wind, temperature etc) Human resources may feel challenging but, when you compare it to trying to get it to rain or for the thrips to disappear, it’s a walk in the park! As farmers, everything we do is unbalancing nature so sustainable farming is a precarious balancing act of keeping our destruction minimised and restoration maximised. Jaff warns us to consider this key, in everything we do.

Therefore, environmental sustainability is the key to all sustainability. Farming against nature, with harsh chemicals and irresponsible applications, is a sure-fire way to unbalance the environment and set you on a short trip down a dead-end, one-way path.

The key to reaping the long-term rewards of investing in macadamias is SUSTAINABLE FARMING; minimise environmental destruction and maximise environmental restoration.

Jaff is optimistic about the consumer market potential though – especially because there are so many untapped avenues. This operation will be opening its own processing plant and developing suitable markets with down-stream product.

And that’s a wrap! What a day 🌟 I drove away with an immense sense of gratitude that these four men graciously shared their vast accumulated knowledge for nothing more than a thank you!

I had a letter from a reader today and here is an excerpt: “I am just glad that I can learn from farmers who have been farming Macs for years through your Jaff articles, thank you for the effort you are putting into the articles. I just want you to know how much I appreciate your content.” There would be no content if it wasn’t for selfless farmers and so I accept the thanks from this future farmer on behalf of all the selfless Jaffs.

Let’s keep equipping farmers for excellence and success by sharing knowledge and expertise!

Until next time,

D