Micheon has a fascinating story; one I was privileged to hear and be able to share with you all. He is humble, eager, gentle and hard-working. A father of four grown children, of whom he is very proud, and husband to Rachel, whom he clearly adores.

Micheon farms in Noodsberg, a predominantly German community who has welcomed him into their ranks with support and comraderie at every opportunity – in fact, I had to suppress a tear when I listened to Micheon express his profound gratitude for the help he received from his neighbours when he first arrived on this farm. At a loss for adequate words, he humbly admits that, if it was not for Errol and Elmarie Thole, Ant Edmonds and a few others, he would never be where he is today.

| Date interviewed | 15 February 2019 |

| Date newsletter posted | 8 March 2019 |

| Farmer | Micheon Ngubane |

| Farm name | Tete Somahashi Trading Enterprises |

| Mill | Noodsberg |

| Distance to the mill | 55 kms |

| Area under cane | 234 hectares |

| Cutting cycle | 22 – 24 months |

| Av Yield | 87 tonnes per hectare |

| Av RV | 12.48% |

| Varieties | N12, N48, N41, N39, N52 |

| Soil type | Black Loam, Glen Rosa and Hutton |

| Diversification | 9 hectares of wattle |

But let’s go back to the beginning because we can all learn from the tenacity Micheon has lived out in his journey to this point in his life – it hasn’t been easy.

He began life in abject poverty; the eldest of seven children. His dad was a stripper (I cautiously asked for clarification on that and learnt all about bark-stripping on wattle timber farms – whew), mom was a farm labourer.

He was born on a farm in Seven Oaks (about 65kms from this farm) in the early 1960s. His early education was at a local farm school. Getting to school every day was a mammoth task but this is where Micheon’s passion for education began. He would have to run, walk or cycle (if his dad’s bicycle was available) 25kms to school every day. He then did a couple years of High School at Mpolweni – he and his brother stayed in a room his mother rented; it was owned by an awful lady who made the boys work very hard and fetch water from the river in 210lt drums which they had to roll uphill to the house every day. In those days black education didn’t go through to matric and Micheon went back to the farm with a Grade 10 equivalent. The pain of these childhood years is etched into every word Micheon shares about this part of his life – he says it is hard for him to speak about it with his children but he knows it’s important for them to know his history and how blessed they are to be thriving in our country today. I am humbled that this accomplished man was prepared to expose his vulnerabilities and share his early years. I trust that we can all appreciate the unimaginable hardships most of us have never had to endure. For me, it makes the celebration of his current circumstances so much sweeter.

Once back at the farm, he started work at the bottom, loading timber onto waiting trucks BY HAND but it didn’t take long for his willingness and capabilities to shine and he was soon promoted to clerk. Over the next few years, he moved up through the ranks but was aware that he needed more education to be of real value to the company – he wanted a tertiary education but had to complete matric first. Eventually, at 23 years old, he got his matric. His promotions at work enabled him to educate most of his younger siblings and buy his parents a piece of land in Swayimani to retire to.

Yet more promotions came in the following years and Micheon fondly remembers Kevin Bingham, with whom he worked closely, who believed in him and supported his blossoming career. In 1996 Micheon enrolled at RAU (Rand Afrikaans University) as a correspondence student, intent on finally attaining the tertiary education he had coveted for so long. At the same time, he also worked as a reservist with the SAP in an effort to support his growing family. When, in 1999, he failed to attain his Diploma in Transport Management because of a 49% (pass mark was 50%) in one subject, he came so close to giving up. And here’s comes the biggest lesson in Micheon’s story – the one that has flavoured his entire life – NEVER GIVE UP; focus on the goal and work towards it even when you feel you aren’t making progress. Micheon managed to summon up the courage to endure another year of full-time employment, part-time work with the SAP at night and studying in whatever time he wasn’t sleeping or engaging with his family and he FINALLY earned his tertiary education, when he was almost 40 years old.

Work-wise, Micheon faced a few tumultuous years when Mondi bought HL&H out of the farms he was working on. He continued to study, adding short courses to his resumé and building his career but he just wasn’t feeling fulfilled or appreciated, and was being moved around excessively. When his youngest son was born, and he was not able to be present at the birth, it was the final straw and he resigned. It didn’t take long for him to be snapped up and he continued his valuable contribution to the wattle industry through SAWGU, initially, and then NTE. He was very happy here and worked with them for many years but, in 2010, an announcement in the Witness (newspaper) set him on a different path.

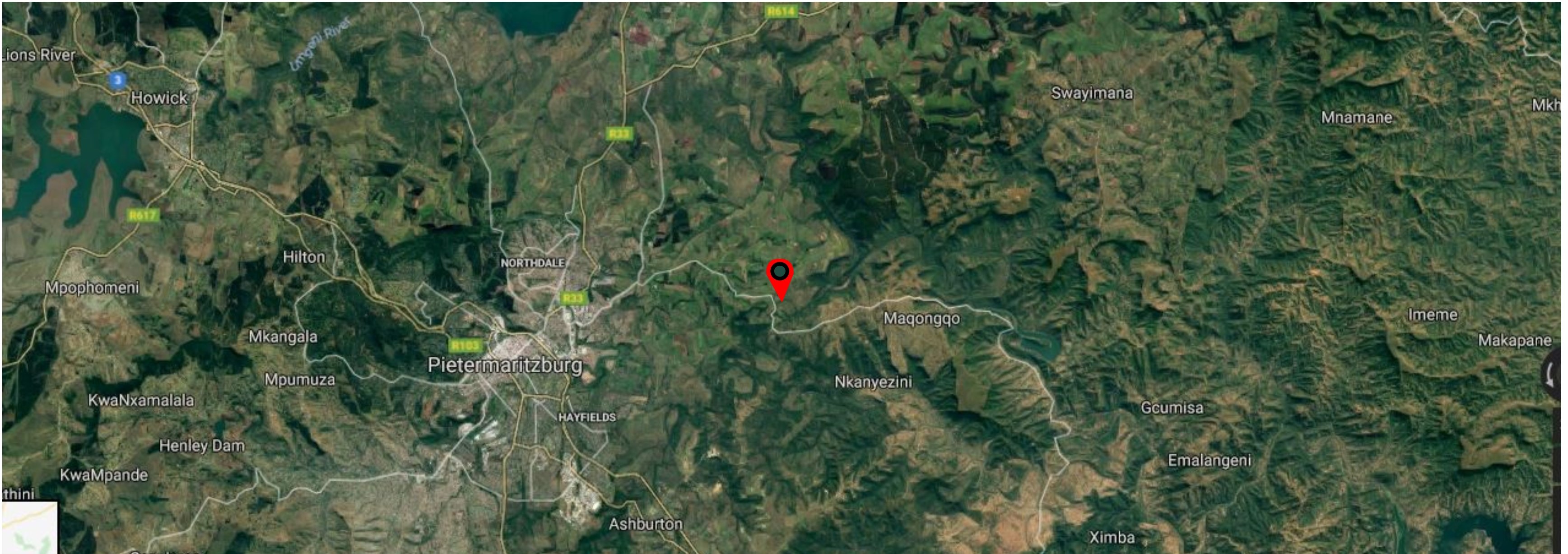

Rachel had been encouraging him to use his knowledge and experience to do something for himself and this proved to be prophetic when he read that the Dept of Land Affairs was looking for farmers to be a part of their agricultural reform programme; they had bought two farms in the Table Mountain area and needed promising black farmers to get involved. Having nothing to lose, Micheon applied. Over a year (and many rounds of interviews, detailed applications and short-lists) later, Micheon stood on the road outside a farm that was his, all he had to do was turn it into a success. The problem was that it was so neglected, he couldn’t even access it! Had he just made the biggest mistake of his life? He was too scared to tell Rachel what he’d done and stalled until the Department said he had to occupy the house immediately. So, on the 11th September 2011, he guardedly took the keys and secured the farm. Now what?! He had a job, his wife and family were happily settled in Pietermaritzburg … what was he doing? He was following a passion to excel; obeying that small voice inside that reminded him “you were made for great things.”

He didn’t even have a bakkie and, as this is the steepest farm in this farming district, a 4×4 was mandatory. He decided to take leave and assess the situation. He recalls the first day when Ant Edmonds came over, in his Landcruiser, and offered to take Micheon around his new farm. Armed with cane knives and determination, they set out to cut a path into the 228 hectares of sugarcane, wattle, bugweed and lantana plantations. Some of the cane was about 40 months old. The situation looked dire and that night, when Micheon got home, he seriously questioned whether this was something he really wanted to get into. But Ant’s encouragement bolstered him; his words “I know you’ll make it” still inspire Micheon when he’s having a bad day. Rachel’s support also fortified him – she said he cannot walk away from this without even trying.

Another thing that encouraged Micheon was the staff, some of whom had stayed on the farm in the hope that a brighter future lay ahead. The most prominent of these people is Khalipha Xhaya, Micheon’s chief supervisor. She too encouraged him to tackle this giant and give this reformation story a happy ending.

And so they started burning … they woke up at 4am every day so that they could do things cautiously and be able to see any ‘nyoni’s’ that threatened the neighbouring farms; Micheon was terribly concerned about his neighbours, knowing that they were all watching his every move. He didn’t want to jeopardise their farms at all. They cut cane and loaded it into a quarry trailer by hand. The previous owner had reneged on his commitment to let Micheon buy his equipment so he had to do it with the bare minimum he could rustle up, which was one small tractor, the quarry trailer and two planks which they all walked with each armful of cane. Micheon displays his sentimental side when he later showed me these two planks that will always hold a special place in his heart as representation of the challenges he’s overcome on this farm.

Centre: Khalipha Xhaya, Micheon’s main supervisor. She is flanked by his original trailer and Micheon, showing me the planks they used to load cane into the trailer by hand.

Centre: Khalipha Xhaya, Micheon’s main supervisor. She is flanked by his original trailer and Micheon, showing me the planks they used to load cane into the trailer by hand.

In October 2011, they delivered 3000 tonnes to the mill, all cut and loaded by hand with 10 cutters. Micheon is almost overwhelmed by emotion when he recalls these early days, not because he achieved so much but because he was helped so much; Khalipha rallied cutters and motivated staff, Errol and Elmarie Thole sold him a 2nd hand Bell, which he couldn’t pay for, so they agreed to a mill cession to cover the cost. Micheon had always been a kind and gentle man – could it be that ‘karma’ was repaying him? He’s not sure but he does believe that, regardless of where you are in life, it is vital that you are respectful and fair to all people at all times.

The end of 2012 was a turning point; he resigned from his job at NTE, Land Affairs audited his operation and approved a loan for replanting and ratoon management. A joint venture with Illovo and the uThombo initiative helped him re-establish further cane fields. In total, 120 hectares were replanted. 2013 was also the last year of Land Affairs holding his hand – he had passed the three year ‘probation period’ and was released to continue on alone. Micheon had graduated (again)!

CANE FARMING

Among the early harvests, of the inherited crops, was a field that delivered 8 tonnes per hectare with an RV of just 4%. We can appreciate how far he’s come in 8 years when this last season closed with a total delivery of 9543 tonnes at an average of 87 tonnes per hectare and 12,48% RV. One field even gave him 151 t/h! Micheon literally glowed when he announced these results. They had exceeded his expectations and he is justifiably proud of all his team produced. He gets into the details of what got him there with animated excitement.

60% of this farm is on steep slopes, inaccessible to tractors, so land prep, planting, harvesting and stacking is still all done by hand, only now he has side-loading trailers and a few tractors. On the balance, where the fields are accessible by equipment, he runs a cut and windrow operation, using a Bell to load in-field. The pictures below give us an idea as to how steep this farm really is:

The soils are a mixed bag, but he does have lots of rich black loam, and some Huttons. And to balance it out, there are also the challenging Glen Rosas.

PLANTING

Recently Micheon has started to plant his own seedcane and he believes this has helped him eradicate the odd eldana presence he was experiencing.

Micheon, with some N52 seedcane

Micheon, with some N52 seedcane

As far as the planting process goes, Micheon’s is fairly straight forward; Roundup, plough, soil sample (if one hasn’t been done in the preceding 5 years), disc, identify a suitable variety for replanting, ridge, lay seedcane in at 1,5 stick placement, chop with cane knives that have been dipped in Jeyes fluid, fertilise and close. No anti-thrips dosing.

Ridging is done by tractor where possible but most often, by hand.

Ridging is done by tractor where possible but most often, by hand.

There are a couple of pearls we can pick up on though:

- One lady applies fertiliser, by hand, for everyone. She is a pro at this task and achieves accurate application throughout her 800m2 task every day.

- In closing with a hoe, the staff have to move forward in their row so that they consciously compact the soil on top of the seedcane with their body weight. No one is allowed to move backwards. The planting task is 50m x 16 lines and includes stick placement, chopping (each person has their own knife and container of Jeyes fluid), closing and compacting.

VARIETIES

When Micheon arrived, all the cane was N12 and although this is a highly successful variety in this 24-month environment, Micheon did extensive soil samples and has recently found great success with N48 and N41 which he is planting up enthusiastically. He knows this change will further improve his results but his patience shines through when he reminds me that Rome wasn’t built in a day.

Recently he leased 9 hectares from a neighbour and has planted N52 for the first time. His season will open with that variety and he’s excited to see what it yields. Harvesting might be a little slower as it started to lodge at 18-20 months already.

N48 at 4 months

N48 at 4 months

Variety trials: N12 on the left and N48 on the right, planted within weeks of each other to accurately compare outcomes. You can see why Micheon is favouring the N48.

Variety trials: N12 on the left and N48 on the right, planted within weeks of each other to accurately compare outcomes. You can see why Micheon is favouring the N48.

PESTS

Back in the beginning, when P&D visited the farm in their Corsa bakkie (almost as ineffective as Micheon’s vehicle at the time) they handed out burn orders left and right. Since then, the extensive replanting programme sealed the fate of this insect and nowadays, P&D draws mostly blanks. He believes that growing his own seedcane has been the final nail in their coffin.

So, wonderfully, this is a pesticide-free farm. Not so much when it comes to weeds though …

WEEDS

These are definitely the thorn in Micheon’s side. In his own exasperated words, “Barbie grass drives me CRAZY!” He sprays and hoes, even after the cane has canopied and still, the determined grass pops up everywhere, producing his biggest headache.

In the standard war on weeds, his programme involves an initial spray when the cane has germinated and 3 to 4 leaves are showing. This application is mixed with a sticking agent to lengthen its efficacy. 16 weeks later he sprays again. Both of these are blanket sprays using tractor applicators wherever possible and knapsacks on the hillsides. He has a team of four ladies that are permanent sprayers.

Besides the dreaded Barbie grass, Micheon also singles out Star grass, lantana and bugweed with a mercenary glint in his eye. He has dedicated one man (pictured below), armed with tools and poison, to fight this war on a full-time basis. His long-term aim is to have this farm completely alien-free.

FERTILISER

Micheon plants with 2:3:4 at a rate of 250 – 350kgs per hectare, depending on recommendations post soil sampling. He does not use any other supplements when planting. Later, the fields are top dressed with a max of 450kgs per hectare of 1:0:1. Ratoon fields get either 2:0:3 or 5:1:5, depending on recommendations, with a 1:0:1 top dress just before canopy.

Lately he’s been trialling CMS and believes this may well be a key to further improving his yields. Partly because the liquid fertiliser is placed ON the sets, making the WHOLE dose available to the cane plant, rather than being spread in the inter-rows where weeds may well soak up the sustenance.

CMS application to the fields – you can see how it is applied to the cane plant, rather than the inter-row.

CMS application to the fields – you can see how it is applied to the cane plant, rather than the inter-row.

Urea vs LAN is another contest Micheon is busy assessing. His eager, enquiring nature sparkles with anticipation at the outcome of all the trials he does. Mostly, he is excited to teach his sons, based on the outcome of each trial, not only what his recommendations are but also the importance of questioning and assessing their options, in all facets of life.

Granular fertiliser application

Granular fertiliser application

Micheon’s trials consider both the financial analysis AND results of the options; and he emphasises that just because one way seems more expensive initially, you have to make sure that you have factored in all the costs and benefits before making a decision. An example of this is liquid CMS (transportation, storage, mixing to specific soil samples and application all included in the price) vs granular fertilisers, where the cost of all these logistical requirements need to be quantified and included in the comparison.

HARVESTING

Moving onto a farm that had not been harvested for almost 3 years made this the first area he got stuck into. It was also the area into which his neighbours’ assistance was most valuable. Micheon turns introspective as he recalls the final day of the 2013 season; it was pouring with rain and he was never going to get his cane delivered had it not been for the help from Julius De Lange and Errol Thole. They brought their tractors over and all the tractors worked together, pulling each other, and the cane, out of the fields until every last stick had been delivered to the mill. Still looking down, Micheon quietly acknowledges that he will never know how to repay or even thank them for what they did that day.

But, he’s come a long way since then and has equipped himself well in terms of equipment and a carefully thought-out harvesting plan that starts with planting. This is a strategy Micheon places high emphasis on; I’m calling it his Strategic Burning Plan. As Micheon plans the replanting of his farm, he ensures that neighbouring fields are at extremes in terms of age. The purpose of this plan is to minimise runaway fires. You can only really appreciate the necessity of this plan when you see the steep slopes – it’s not hard to visualise a fire tearing its way all the way to the top and, as most of these hills are inaccessible to vehicles, there’ll be no way to fight it effectively.

These three pictures clearly show the strategic burning plan illustrated in the panels, all at varying stages of growth.

These three pictures clearly show the strategic burning plan illustrated in the panels, all at varying stages of growth.

Another factor in this harvest plan is weather; hilltops are harvested in the rainy season, dry months are reserved for fields that can take vehicles but are prone to bogging down if there’s rain. All these elements have to be thought about and planned for when timing the plant. And sometimes, all your careful planning is derailed, like it was at the end of last year when low rainfall figures made Micheon defer his planting operation until more rain fell earlier this year.

Another facet of harvest-prep I found intriguing was that Micheon doesn’t use drip torches to start the fires. Instead, he applies Roundup to a narrow border around each field. The weeds here turn to kindling and fuel the harvest fires. He saves petrol and all the tools that go with the drip-torch way of burning.

The ‘Roundup-ed’ perimeter is clearly visible in this field of 24-month-old N12.

The ‘Roundup-ed’ perimeter is clearly visible in this field of 24-month-old N12.

Ripeners are not used here at all as Micheon prefers to retain the flexibility that ripeners would rob him of. He’s also not convinced that the cost vs benefit outcome would be favourable. But, perhaps that’s something he can leave for the boys to trial when their time comes.

The cutters here are a lively bunch and average 6 tonnes per day per man. Khalipha manages them although Micheon is present during every burn and therefore has a close eye on the entire harvesting operation. A 6-tonne trailer is loaded in-field when possible, otherwise cut-and-stack is the norm, using side loading trailers, placed at the bottom of the field. Agritrans moves the cane to the Noodsberg mill during the afternoon and evening. On windy days the cutters hoe weeds from recently harvested fields, achieving a task allocation of 100m x 6 rows.

Windrows and Bell loaders are used where possible, otherwise it’s cut-and-stack with side-loading trailers at the bottom of the field.

Windrows and Bell loaders are used where possible, otherwise it’s cut-and-stack with side-loading trailers at the bottom of the field.

LABOUR

Micheon is a very wise man. He knows that a woman can do the job of 6 men. (Okay – he didn’t actually say that, but I am sure he meant to ) He did say that women are far less prone to drinking, absenteeism and attitude. His top three supervisors are all women with Khalipha in charge overall. She also controls stock levels and record-keeping. Sounds like someone should definitely look into cloning her.

Micheon is not immune to labour issues though and, when he’s away from the farm, they seem to play up more. Having his eldest son, Philani, who is a varsity student in PMB, in and out does help in keeping an eye on things. At the end of the day, Micheon advises that you keep accurate records of anything labour-related (right down to when and what you issued clothing-wise); it’s an arduous task but pays huge dividends when you run into sticky situations. Despite people challenges, Micheon still prefers employees to contracting as they are far more invested in YOUR operation.

Micheon also advises that you foster a close relationship with your staff – he likes to take the labour out to the fields himself every day and set them up in each task. He also spends time walking the land alongside his supervisors, especially during planting season.

COMMUNITY

The farm borders the local Table Mountain community which brings inherent challenges to the mix; poachers and unmanaged cattle being the worst. It has been very difficult to stabilise but he thinks they are finally living alongside each other with mutual respect and understanding. He spent many years explaining how many people this farm has to support and that rogue cattle are stealing from these people. In return for respect for his property, Micheon assists the community with ploughing, firewood, grass-cutting, vehicle recoveries and repairs as well as water deliveries when required.

DIVERSIFICATION

Micheon is a dedicated sugar cane farmer who is not concerned about the current rush to diversify. Some of the terribly steep land, he uses for wattle because it is fire-resistant and helps to prevent soil erosion. This, he harvests but is not reliant on it as part of his sustainability plan. He is also running a few head of cattle but this is also not an income generating sector.

Given his long and involved career in timber farming, specifically wattle, his knowledge and way with people is still valuable to that industry – so he consults periodically, but even this is being cut back more and more as the farm demands his full attention.

ADMINISTRATION

Micheon is far more farmer than administrator. Rachel assists with capturing staff records and related pay-roll tasks, for which he bought Plan-A-Head software and Elmarie Thole has always been amazing in assisting them with this. Beyond that, Micheon employs the services of local people to provide accounting services and budgeting guidance.

Micheon is also deputy chair on the local Canegrowers committee. He knows that he makes a valuable contribution in terms of transformational representation and is grateful to this organisation for all the work they do for sugar farmers across the industry.

FAMILY

Clearly Micheon is family man; he and Rachel are almost done raising four beautiful children successfully. First born is Philani. He is busy with a BComm degree and will probably follow a corporate path. Next is Nompilo. She has a law and teaching degree and St Marys in Kloof is currently the proud employer of this special history and isiZulu teacher. Ndabezinhle (Number 3) is currently in his third year at Cedara and is planning a future on the farm, along with his younger brother, Ntandoyenkosi, who is a matric student at Weston Agricultural College. Another farm is on the cards and the purchase of this will sync well with the boys coming into the fold with all the knowledge their academic years have blessed them with.

Rachel was a full-time maths and science teacher (yes, I was starting to feel woefully outwitted by this academic family) but has since resigned to fully support the family business. And a true family business it is; Micheon has purposefully orchestrated that the business is independent of him and, should anything happen to him, it will continue to thrive. Rachel and all their children are shareholders with signing powers.

And that brings me to the end of my visit on the Ngubane farm. I’m sure you can attest to the fact that this is a remarkable land redistribution success story and one that I am honoured to have spent time in. Thank you for having me Micheon and Rachel. I look forward to seeing the Ngubanes enjoy long and happy lives, succeeding in this industry for many generations to come.