Mark is one of those rare gems that not a lot of us get to interact with. In fact, he almost cancelled my appointment at the last minute (thank you Mark for not making that move). Like so many farmers, he prefers to stay “in his lane and out of the spotlight”. And, let’s face it … what does he gain by having me take up most of his day? Nothing!

So, thank you Mark, for opening up your farm, home and family to SugarBytes – there are going to be many grateful farmers out there.

| Date interviewed | 31 January 2019 |

| Date newsletter posted | 25 February 2019 |

| Farmer | Mark Brand |

| Farm name | Selsdon Park Estate |

| Mill | Umzimkulu |

| Distance to the mill | 35kms |

| Area under cane | 116 hectares |

| Cutting cycle | Ave 13 months |

| Av Yield | 70 tonnes per hectare |

| Av RV | 12% |

| Varieties | N39, N41, N56, N59 |

| Soil type | 90% Recent sands |

| Diversification | Macs – 25.2 hectares |

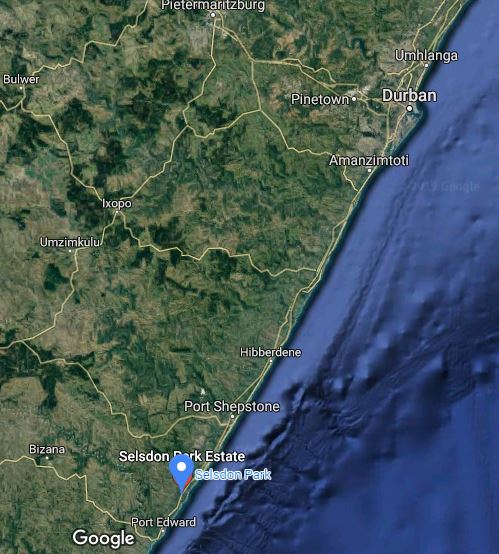

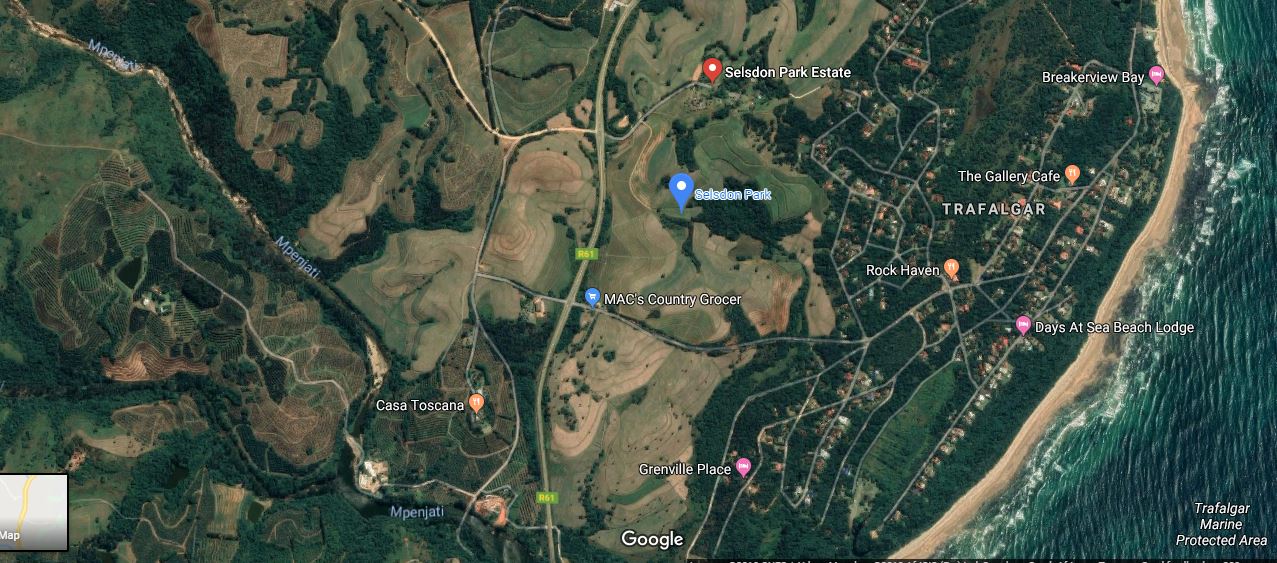

Mark and Megan are the most southern commercial sugar cane growers IN OUR COUNTRY!! Besides that, their farm is right on the coast so, if we are ever interested in learning from farmers in marginal areas, this is the opportunity.

The map below shows where Selsdon Park Estate is located.

Let’s get straight down to business and see how he makes a success despite being on the fringe of feasibility.

(For any of you who really enjoy the ‘History’ part of our SugarBytes articles, fret not; that’s all here, just a bit further down …)

PLANTING

Right from the outset, we realise the importance of pushing this crop hard, just to make it viable – hence there are no field rests before replanting. Mark acknowledges that planting a break crop would be advantageous to the soil. He does compensate, to a large degree, by trashing 95% of the farm.

And doesn’t that trash cause an issue when trying to get new cane into the fields? No – Mark uses a “cultar” wheel which cuts through the trash blanket. After eradicating the previous ratoons, using Roundup, they then rip and ridge in one pass and replant with fresh seed. This farm practices minimum tillage but also minimum in-field traffic.

Depending on how old the seed is, it is planted double or triple stick and chopped in the furrow. It is not heat treated as Mark does not have any diseases warranting the additional processing. Bandit is sprayed to manage Thrips. Fertiliser is applied, and the furrows are closed by hand, mainly because the farm is quite steep in most parts.

Mark prefers using varieties that canopy quickly, like N56 or N39 although, with the trash blanket already suppressing most of the weeds, it’s not a vital consideration.

HARVESTING

Marks choses to trash rather than burn, for a number of reasons:

- As can be seen in the map above, Selsdon Park has a high density of residential neighbours, who tend to dislike the ‘black snow’ that falls after a cane fire.

- Soil health is enhanced by the supplementation of trash.

- By trashing, Mark eliminates the tasks and equipment associated with burning, like:

- Watching the wind and having it, and other weather issues, dictate harvesting windows.

- Firefighting equipment and staff at every fire.

- Compulsory (personal) early morning starts, to be present at every fire, throughout the season.

- Even cutter-smocks last longer in this cleaner environment.

Mark’s Dad started with the practice of trashing and it has faded away once or twice over the years for reasons such as drought or labour shortages, but Mark has always brought back what he feels is the best practice for his farm. This farm is predominantly sandy soils, which definitely produce better cane when supplemented with this organic matter. The benefits are seen in weed control (and therefore the farm’s chemical expenditure) and soil moisture.

Mark explains that every farm has ‘imithetho’ (rules or entrenched traditions specific to that farm). Green cane harvesting is one of those imithetho here at Selsdon. The cane is topped in the air; the cutter grabs hold of a few sticks in one go, he then swipes once down either side of the cane, tops the taller pieces first and then a second pass of the knife tops any shorter sticks. He then base cuts in one swipe and lays the cane down on the stack. By topping in the air, the cane knives stay sharper for longer (no abrasive sand to blunten them) and the topping is far more accurate (no green tops on the cane and no cane left on the tops).

There is almost no in-field traffic permitted so stacks are built either on the road (and loaded with a rear-tipping Evans trailer) or on the bank, next to the road (and loaded with a side-loading trailer). In the odd fields, that are flat enough to accommodate tractors and large enough to warrant it, loading takes place in-field. Mark explains that the trash blanket helps to defray a lot of the compaction the equipment would inflict if it wasn’t there.

The trailers are all single cable and I wish I had been here in-season to see how these loaded.

After the harvest, hand-pickers gather any cane left in the fields and this is also sent to the zone.

Farmers have many reasons why trashing won’t work on their farms but the most common reason is cutter resistance so I asked Mark about this; “If people know what to expect, (trashing, top in the air, no in-field loading) then they are comfortable. Making the change is the hard part. But once it becomes imithetho, life moves on … just with healthier soil,” was Mark’s response.

The cutters are paid per tonne and average out at 3,5 to 4 tonnes per day. The older guys can do up to 5 tonnes.

Although Mark is a qualified Diesel mechanic and therefore the perfect candidate to be running his own haulage trucks, he chooses not to. He has other supplementary businesses that eat into his 24 hours every day. Haulage is therefore outsourced to a contractor who hauls from the zone, 35kms to the Umzimkulu mill.

VARIETIES

Right now, N39 constitutes the majority of the crop but N56, N41 and N59 are making inroads.

Although N31 is a very hairy variety and therefore disliked by the cutters, Mark plants one field of it. It’s a corner field, on a very busy intersection, which is highly prone to theft by holiday-makers and pedestrians in the area.

Megan and Justin provide perspective of this mammoth cane. It was N55 plant cane at 16 months old. The valley-bottom-benefits clearly visible.

Megan and Justin provide perspective of this mammoth cane. It was N55 plant cane at 16 months old. The valley-bottom-benefits clearly visible.

WEEDS

The trash blanket (brilliant weed suppressor) saves Mark on one spray and he therefore only sprays ratoon cane with herbicide once. He consistently changes the chemicals used, thereby minimising resistance and targeting exactly what is present in a particular season. A hand-weeding team first clears the fields then, as soon as the lines are visible, the herbicide is applied with knapsack sprayers.

Mark is justifiably proud that there are no invader plants on the whole farm, even in the natural areas. There are many walking groups that use the property and they keep him in check. He’s recently been informed that a fern he thought was indigenous, isn’t, so he will be investigating that shortly.

Plant fields receive a dose of soft herbicide at 2 to 3 leaf stage, then a hand-weed and later, a long-term herbicide spray down.

Mark points out what uncleaned herbicide tanks or knapsacks can do … the gap seen above was caused when someone used an unrinsed knapsack, previously used to spray Roundup, when appyling oxidate to the young cane.

Mark points out what uncleaned herbicide tanks or knapsacks can do … the gap seen above was caused when someone used an unrinsed knapsack, previously used to spray Roundup, when appyling oxidate to the young cane.

FERTILISER

2:3:4 is used in furrow, when planting. Ratoon cane gets 6:1:9.

Mark prefers Omnia fertilizer (LAN-based) and splits application 50:50; 350kg’s per hectare at a time. He emphasises that splitting feeds is very important. There’s no way a plant could, or should, take in all its supplementation in one go. Smaller intakes will be far better utilised and therefore far more cost effective in the long-run.

PESTS

With an average 13-month growing cycle, Eldana has not been a problem. Mark is considering extending this though and is aware that he is going to have to factor in Eldana issues if he does. Currently, only plant cane is carried over.

He does seem to have a nematode problem though; this he treats with oxidate which is sprayed directly on to the leaves at knee-height.

Bandit is used in the furrow at planting.

Rust was a short-term issue, on N29, which he dealt with by removing the variety completely.

This farm is definitely not short of beauty, and all natural areas are maintained.

This farm is definitely not short of beauty, and all natural areas are maintained.

RIPENING

No ripening; Mark knows that, with such a short growing cycle, all 56 weeks are essential to achieving decent yields. To sacrifice almost 15% of this time to ripeners means that he will need to realise at least 17,5% more on current RV (ie: over 2%) to compensate. He’s not convinced that this is realistic, especially when comparing his results with those who do ripen. The inconsistent outcomes concern him.

DIVERSIFICATION

Selsdon Park’s chief diversification comes in an unusual form – horse-riding. But, given their proximity to one of SA’s busiest holiday destinations, it’s no surprise.

About 20 years ago, Mark’s daughter wanted a pony (we’ve all been in this movie) and then he needed another horse for Megan to ride with her. Then, when the riding school across the road closed down, he found himself rescuing those horses. The drought and associated Eldana struggles in the 90’s made cane farming tough during that period and he had already been advised to diversify out of farming. By cleverly taking over cellphone numbers when the other Outride businesses closed down, Mark has built a substantial stand-alone business that supplements farming well. They now have 19 horses – a mix of ponies, Percherons and Percheron X Shires.

But he has also diversified on the agricultural front:

Macs

About 15 years ago Mark planted 8 hectares of macs. This was way before the MMM (Mass Mac Migration ) we are seeing today – there was very little knowledge to support this new venture and it faced many challenges. Mark gradually stopped taking care of the trees, preferring to focus on sectors of his portfolio that were producing returns.

The original mac orchards, as they are today.

The original mac orchards, as they are today.

Now, he’s refocused back on this nut-tree, having learnt a few lessons from his earlier schooling:

- Mark found that rooted cuttings are not ideal and advises that farmers rather use grafted trees.

- The trees need to be around 1m high when you establish the orchard.

- Irrigation, especially during the early years, is essential.

- Wild life (buck mainly) annihilate young trees. Netting bags are not enough protection. Sticks and proper barriers are vital.

- Macs are finicky and require plenty of attention.

- Don’t put all your eggs in this basket. The cashflow that cane provides is an essential lifeline.

- Aspect is important when selecting land to establish the orchard.

An illustration of how buck, sharpening their horns, have damaged this young tree.

An illustration of how buck, sharpening their horns, have damaged this young tree.

Now, Mark has 25.2 hectares of macs with plans to expand.

He advises that good use is made of the land in between the rows while the trees are young. He plants eragrostis hay which he bales and uses for his own horses and sells the excess.

Drainage is important, although, on this farm, because of the sandy Recent soils, ridging is not necessary. More advice from Mark is to ensure that your lines and ridges are kept on the contour and not going down the slope as this will cause soil erosion. Although drainage is important, so is moisture conservation … Mark advises that trees are well-mulched. We did say this is a finicky lot!

Mark has planted 788, Beaumont, 816, A4 and is about to plant Nelmac 2. This broad range of varieties is to spread the harvesting – 788 tend to be ready early, followed by the Beaumonts. Although his are too young, the 816’s should be next. This variety tends to take a while to get into production (on average, about 2 years longer than the others) but they produce well-sized, good quality nuts when mature. Timing harvests is proving to be tricky; if the season runs late (nuts are not maturing when they should) you are stuck between deciding whether to harvest immature nuts or wait and risk damaging the flowers (spraying too late blows the flowers off). Finding the perfect middle-ground is challenging. But, it’s one that both Mark and his son, Justin (who is taking the lead in this new crop), are enjoying.

Mark is encouraged by the healthy nuts on this one-year old Beaumont tree.

Mark is encouraged by the healthy nuts on this one-year old Beaumont tree.

Because Mark has been taking out cane to plant macs, he has an observation that most cane farmers, who are choosing to rather make use of unfarmed land, may not be experiencing; the poor start of these orchards makes him wonder what the residual effect the many years of chemicals, used on the cane (and most likely still in the soil), are having on the juvenile mac trees. Over-herbiciding cane fields may well cost farmers when they come to diversify. This lesson can be carried into any other crop old cane lands are used for.

These original, mature mac orchards are producing well, despite their rough start.

These original, mature mac orchards are producing well, despite their rough start.

LABOUR

The greatest advice Mark has in this realm is “Don’t task.” He tasked by area (and therefore volume of chemical) for many years and stopped it when he discovered that chemicals and fertilisers were being poured out. Bags of poison were even being buried!

Now, he operates a full working day and when staff have completed the daily chore they come back to the yard where they wash equipment, pull weeds around the yard, move sand, firewood or refuse. The change, two years ago, has definitely translated into a healthier, well-kept, more productive farm. The chemical bill has come down and the wage bill hasn’t changed ie: same productivity levels as before!

All staff live on property and enjoy well-maintained accommodation.

All staff live on property and enjoy well-maintained accommodation.

MECHANISATION

This is a Ford and John Deere man. Mark has recently purchased a John Deere cab tractor for spraying macs as he found them to be a lot cheaper, which is refreshing to hear about the green machines. He believes they are a great product, at a great price. Justin does all nut spraying in his beautiful new ride, complete with aircon and sounds. It’s very important that this task is done properly.

Being a diesel mac, Mark is able to keep his tractors for a long time. He stays on top of drivers; supervising operating standards and he maintains the equipment himself. Every off season, the machines are serviced and repainted so I was fortunate to catch them looking supreme.

He also runs specific tractors for each task; usually people multi task their tractors but he says that, this way, he isn’t changing arms and hooking and unhooking constantly. Although he has more tractors than necessary, each one does less hours.

A self-confessed hoarder, he also has two of everything. This saves downtime and enhances the business’ productivity.

HISTORY

At last a little on what road brought this amazing farmer to this spectacular place …

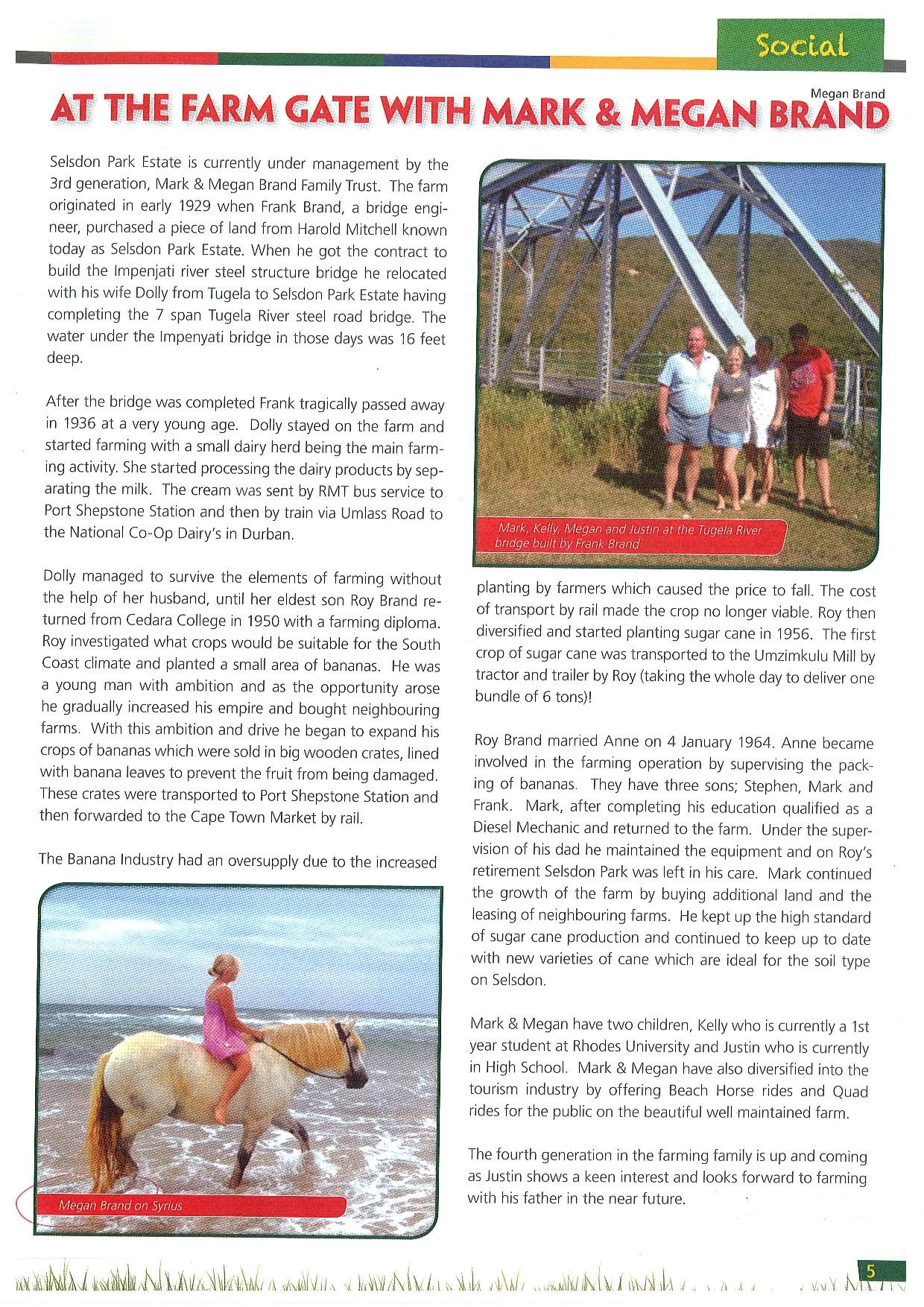

Mark’s grandparents hale from Scotland; his grandfather was a bridge engineer. He built the multispan bridge over the Tugela river – here’s an article regarding that noteworthy feat:

This accomplished engineer bought Selsdon Park while building the bridge over the Impenjati River, but didn’t farm. He passed away when Mark’s dad was just 6 years old and his mom was forced to take on the mammoth task of farming alone. She started cattle farming and operated a small dairy. When Mark’s dad was old enough, he studied at Cedara and then came home to take over the farm, introducing bananas and then sugar to the portfolio. He picked up neighbouring farms as they became available and, in 1994, he put them into trusts in preparation of handing over to Mark and his two brothers. The boys had to buy their portions, which Mark did, taking 20 years to pay back what he owed.

Mark is a Michaelhouse old boy. He completed his trade at MAN in Pietermaritzburg after conscripted national service. His ‘army days’ were valuable ones, where he learnt a lot about water management and weir construction when he helped repair the weir and canal on the Bivane River near Paulpietersberg; Demoina floods had washed the structures away in 1984. He has since used this experience to construct a weir on one of his own farms.

FAMILY

The Brand family today is a harmonious bunch – Megan has been by his side for “ever” and still supports him in business as well by running the administration side of their enterprises.

Kelly, their daughter, completed her degree at Rhodes University in Grahamstown. She is now a qualified pharmacist. Justin is currently assisting on the farm, having completed his Agricultural Management Diploma at NMMU (Nelson Mandela Metro University) in George, at the old Saasveld campus. They’re grateful that both children have chosen to live on the farm, along with the 9 Jack Russells, 3 Ridge-backs and 4 Border Collies … oh, and one poor cat.

Selsdon Park is a special piece of paradise and, although marginally placed for sugarcane, it is perfectly placed for so much else. Mark is an astute businessman and has made a wonderful success of his portion in life, leaving a proud heritage for his children, for many years to come.

Thank you, Mark and Megan, for having me in your space and for being so warm and open about the lives you lead as committed and hard-working farmers.