Oh gosh, what a happy day!

It was with some angst that I drove back to my school-going turf – I was a “hozzie-dog” at Wartburg Kirchdorf Schülerheim, way back in the late 80’s. Driving back along that road into Wartburg brought back memories of Sunday afternoons when Bob drove us back in the school bus, after a free weekend. The bus was usually very quiet as most of the little ones had stopped crying by then and the rest of us just stared out the windows wondering what the next term held for us.

Despite the sombre mood on Sunday afternoons, I loved my school years – I made lifelong friends in Wartburg, in fact, I even found my husband there! We’ve been married for 25 years and, for him alone, I regret nothing about my time in Wartburg.

It was actually wonderful to go back and learn so much more about the community I had grown up in but knew so little about. The Eggers family had been kind enough to accept my request for an interview and treated me like royalty throughout my EIGHT hours with them.

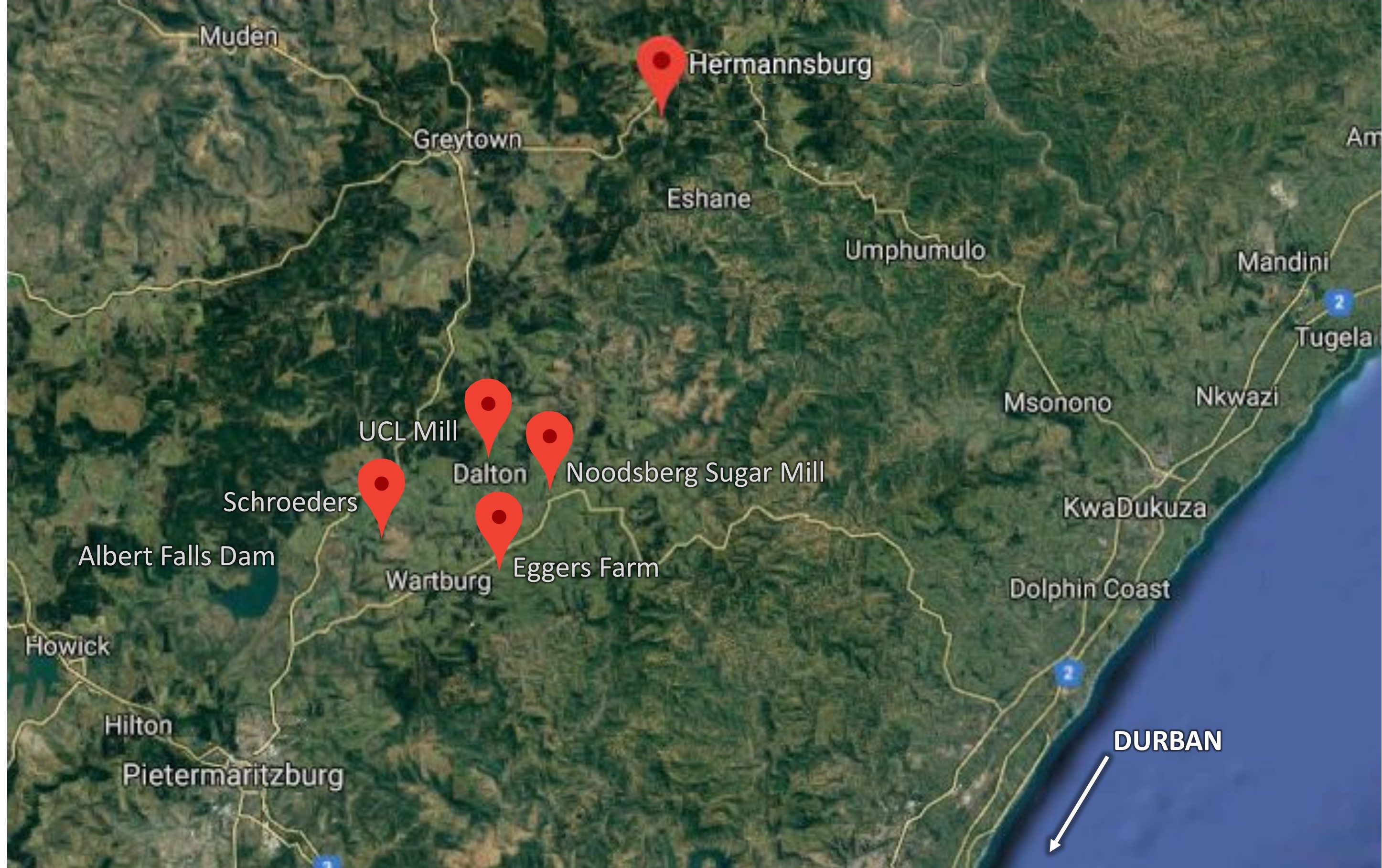

Anyone from the Noodsberg or UCL cane supply areas most probably knows all the heritage of this delightful family so I hope you’ll have patience while I establish the background for farmers from other areas:

| Date interviewed | 23 January 2019 |

| Date newsletter posted | 8 February 2019 |

| Farmers | Heinrich and Ricks Eggers |

| Farm name | Sultan and Nobel of Waterfall |

| Mill | Noodsberg |

| Distance to the mill | 11 kms |

| Total farm size | 410 hectares total |

| Area under cane | 318 hectares |

| Other crops | 26 h pine, 15 h macs (will go up to 30h within next 4 years) |

| Tonnes to mill | 18 – 20 000 t annually |

| Cutting cycle | 21.2 months currently |

| Av Yield | 120t/h |

| Av RV | 12.78 % (Long-term average) |

| Varieties | N12, N54, N16, N61, N48, |

Before kicking off, I think it is important that I share the reason the Eggers’ men consented to an article on their operation being published in SugarBytes; as we all know, most farmers are reluctant to draw any attention to themselves and that is particularity pertinent in this Midlands region. Despite that, they decided to put the interests of others above their own; some of the best cane in the region is being produced in this area and they believe that it’s only right that others be allowed an insight into what is behind that success. So, the Eggers men stepped forward, in the hope that other local farmers will also share their experiences and expose the practices of this phenomenal region. Thank you for being the leaders, Heinrich and Ricks … when we get into the family history, you’ll see that pioneering has always been in the Eggers’ DNA …

HISTORY

Back in the mid-1850’s a missionary ship, the Kandaze, sailed to South Africa, from Germany. A mission station was established at Hermannsburg. The 1870’s brought a severe drought to Europe and poverty forced people to seek out a life in other parts of the world. The Hermannsburg mission station became a destination for many German youngsters.

Heinrich Eggers, together with his brother and sister, boarded the SS Errol in South Hampton in 1877. They each had a bible, some money and a firm instruction to “Stay with church and school”. When the ship landed in Durban, Heinrich got off while his siblings continued on to another mission station in Alice Springs, Australia. He began the long trek inland. Natal had already been settled by the Boers and his journey crossed many of their farms. One night he was met by a rifle and its owner, an Afrikaans farmer, in the Greytown area. Heinrich explained that he was headed to the Hermannsburg mission. Once farmer Havemann had spent some time with Heinrich he offered him employment, should things not work out in Hermannsburg. Honouring the commitment he’d made to his parents, Heinrich continued on to Hermannsburg but eventually made his way back to the Wartburg area. He also encouraged his brother and sister to join him rather than stay in Australia, which they did.

It didn’t take long for Heinrich to find a way to buy his own farm and, in 1886, he became the owner of the farm Doornkop, near Schroeders. This farm is still in family name. He subsequently managed to buy a farm for each of his sons, all in this area.

This remarkable forerunner is Heinrich’s great grandfather. Today I am honoured to be sitting on a farm bought by Heinrich’s grandfather, in 1926, with the fourth (Heinrich), fifth (Ricks) and sixth (Luke) generations in this romantic story of pioneers.

Luke, Ursula, Ricks, Andrea and Heinrich Eggers

Luke, Ursula, Ricks, Andrea and Heinrich Eggers

Back in the beginning most of area was used to grow either black wattle or maize or to farm cattle. But, in 1952, two gents called an urgent farmer meeting at the Royal Show, explaining that they planned to buy the Esperanza Mill (old Sezela Mill) and relocate it to Mason’s Mill – they asked the local farmers if they’d consider planting sugarcane. Being at an average altitude of 1100m above sea level, and subject to cold winters, many crops were considered unsuitable – sugarcane was one of them. Nevertheless, a ‘seed was planted’.

Mr Koch, one of the local farmers, had been bringing cane from Zululand for a while and growing it to use as horse fodder. Seeing that that grew, five brave farmers (incl. Heinrich’s dad) got together and decided to make a bold move. They went to BarwonFarm (about 50 – 60kms towards the coast) to buy some seed cane from Mr Goble. He was so sure they would be unsuccessful in growing cane at the altitude and temperatures they were farming at that he decided not to charge them for the seed, asking instead for a load of wood in exchange for each load of seed. Five loads, each a different variety, made their way to Wartburg and the first commercial cane farming in the area happened on this very farm 60 years ago.

Embarrassed to be trying something so radical, that everyone predicted would bankrupt them, they hid the ‘experiment’ away from the road, behind timber plantations. But the cane took and flourished. Healthy harvests were loaded into rail trucks at the Bruyn’s Hill station and sent to the old Illovo mill, about 200kms away. In 1962 Illovo built a new mill at Noodsberg and today the Noodsberg/UCL cane farming region has about 50 000 hectares under sugarcane.

Heinrich’s dad served The Noodsberg Canegrowers for the next 39 years and the tradition of leadership has continued through the generations with Ricks currently being Chairman of the MGB, and a member of various other committees.

PRESENT DAY

Heinrich and Ricks now farm amicably alongside each other with Ricks being left in charge more often and for longer periods as Heinrich and Andrea start enjoying more sabbatical time, quite often back in her country of birth; Namibia. Together they have raised Ricks and his elder sister and are enjoying their three gorgeous grandchildren.

German’s are known for their discipline and focus. Both characteristics are prominent on these farms, right from their immaculate fields to the clear, tidy desks and detailed spreadsheets, and are major reasons why the operation is so successful. It’s refreshing and inspirational for those of us who tend to pinball our way through life. Andrea told me they’ve raised the kids on three values:

- If it is to be, it is up to me.

- If you’re going to put your chin out there, you need to take it on the chin.

- “So wie du in den Wald rufst so schallt es zurrück!” translated: As I shout into the forest, that echo is going to come back to me.

I found these philosophies enlightening and wonder whether there’s still time to guide my teenagers by them …

SUGARCANE FARMING SPECIALISTS

Heinrich and Ricks agree that good soils are foundational to any successful crop. For them it is important to have independent, detailed, scientific analysis of all their soils to establish a starting point. To this end, local farmers got together in the late 80s and formed Spencer Holley Agronomic Services, with the late John Spencer (formerly Kynoch) as Agronomist, servicing approx. 15 000 hectares. He began by digging 1m3 pits on a 100m2 grid and classified all soils on their farms. This analysis enabled them to not only take applicable and economic corrective action, it also helps them to understand the capacity and limitations of their soils.

FERTILISERS

They continue using SHAS, now driven by Gavin Moore as agronomist, to do soil and leaf sample analysis every season and tailor the fertilisers to suit the needs revealed through those results. A standard goal is to get acid stats down to 0% using lime and gypsum, thereby maintaining and improving soil health.

By using an independent agronomist, they enjoy these benefits:

- He is not focused on a specific crop but rather on the holistic soil composition across your entire agricultural enterprise.

- He is not employed by a fertiliser supplier whose main driver is to sell their products. You can therefore move with his recommendations, confident in the knowledge that it is focused purely on your crop, soil and overall sustainability.

- Farming in this scientific way has lowered their fertiliser expenditure.

- Environmentally aligned programmes are easy to plan in this holistic setting.

- An independent agronomist working across a range of crops often brings fresh ideas and innovations into the industry eg: gypsum. Spencer Holley Agronomic Services actually highlighted and demonstrated the benefits of gypsum to the sugar industry which is also acknowledged and advocated for use where required by the SASRI. The fairly recent introduction of this mineral to our supplementation programmes explains why acidity problems are so prevalent in the industry but at least there’s hope that, with more extensive use of this product, the issue can be addressed.

Ratooning fields:

Part of the recommendations from the agronomist has been to replace synthetic with organic and every ratoon field now gets 8 t/h of raw chicken litter which is applied with a spreader soon after harvest. After this, every alternate inter-row of a ratoon field is ripped and, in this process, 150 – 300kgs / hectare of 1:0:1 is applied at around 150mm deep.

Below is a picture showing the ripping and fertilising in one pass. Ricks is checking to see that the fertiliser is there …

Plant fields:

After a final harvest, a winter crop is planted, this was usually oats but soil loosening mixes are being used now. Besides resting the soil, this additional crop also helps reduce erosion and conserves moisture in the soil. In preparation for replanting this crop is ploughed into the field with no Roundup application if the variety is not changing. Usually, the winter crop suffocates any residual ratoons but, if any survive and the variety in that field is changing, they’ll use Roundup to keep the field pure. 120 tonnes/hectare of filter cake is applied and disked in for planting, especially on poorer soils.

The field is then ridged and 100 – 150kgs / hectare MAP simultaneously placed in the furrows. The double sticks of cane are placed and drenched (using knapsack sprayers) in a mix of Bandit and Easigrow. Easigrow supplies auxins (growth hormones) to the germinating sets. There are trials of a new product called Bandito which pre-mixes these two chemicals but it is, as yet, unregistered.

Ricks has been using Afrikelp on his mac trees. This is also a root growth stimulant made from sea bamboo grown on the West Coast. He is going to trial it on the cane as the application rate is 2 litres/hectare whereas Easigrow is 8 kgs/hectare. He still has to do the maths on the costs of each product and assess the outcomes of his trials but it may be an opportunity to save costs and still enjoy maximum root growth. Gapping has largely been averted since Ricks started using these growth hormone stimulants.

The flat-field furrows are closed with a harrow – see pic below – and the sloped fields are closed by hand.

A 300kgs/hectare 1:0:1 top dressing is applied when there has been some growth. Back in Heinrich’s dad’s days, fertilizer was applied at a rate of 1500kgs/hectare – yields were brilliant but soil acidity went through the roof!

Long growing cycles, like the ones here in the Midlands, mean that the crop ends up going without any additional supplements for a long time. Ricks is therefore considering splitting the 1:0:1 dose, especially on the poorer soils where leeching is an issue. Right now, they are applying some when the cane is around knee height on a day like today, when there is some good rainfall predicted for the next few days.

IRRIGATION

When the Nobel farm was bought, it had a block of irrigation fed by a well-placed dam. Critters had destroyed the pipes and, when Heinrich was looking at replacing them, he was offered a 10-hectare pivot system at a good price. To make the numbers work, the field had to produce a minimum of 80 tonnes/hectare pa, which seemed attainable, so Heinrich went ahead. The outcome has been great even though the pivot is only used to supplement rainfall.

They recently had probes installed and realised how much they’d been over-irrigating. The upside of that is the opportunity to now correct it and thereby save on costs.

VARIETIES

N12 was developed for the Midlands and continues to be the Eggers’ leading variety. Although it is slow-growing – best suited to this colder climate and the extended growing cycles (24 months), it ratoons well with brilliant yields. The field pictured below is on its 14th ratoon, making the original roots almost 30 years old. It is still producing just over 120 tonnes per hectare!

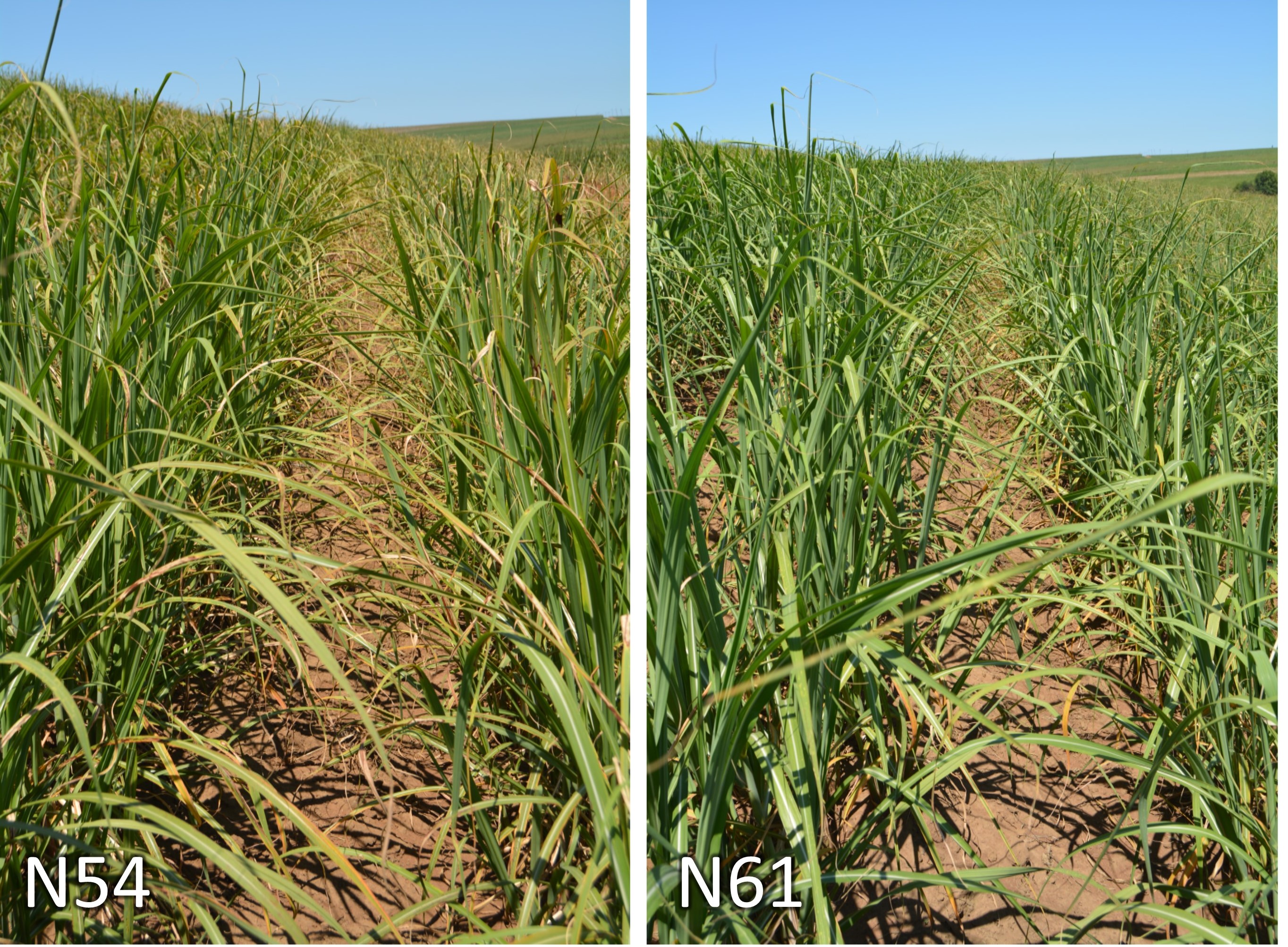

N54, a relatively new variety, is doing very well. Even though it only makes up 14% of the farm currently, its rapid growth (reaches maturity at 14 months) has been a major factor in dropping the farm’s average growing cycle from 24 months to around 21 months. This variety is now favoured in the valley bottoms where the risk of frost is greatest; at least, if frost does kill the growing tip, there is something to harvest before all the sugars disappear. Ricks has been so enthused by this variety that Heinrich had to hold him back from planting everything to N54 until it’s run a bit more of a race. As many have learnt the hard way, some varieties have run out of legs or develop an issue after 3 or 4 ratoons. N37 is an example of a disappointing variety which has been phased out of this farm for that very reason – it seemed to develop rust early on. N31 also hasn’t worked – it grew really fast but the sugar content was unacceptably low.

N16, with its tendency to lodge and break off, is being phased out in favour of new varieties.

N61 also another new variety Heinrich and Ricks are trying. The promise is that it’ll have good sucrose levels. Ricks is just concerned about its population as it doesn’t seem to be keeping up with the N54. Both are shown below at 4 months old.

In the picture above, Ricks is standing facing a test field of N66; a new variety that the local SASRI extension service is trying out. This variety is also slow growing, as can be seen when compared to the younger field of N54 behind Ricks. That might be a part of the plan as there needs to be a variety to come alongside the slower growing, longer cycle N12. It’s too early to make any calls and, at the end of the day, a range of varieties is essential.

In the picture above, Ricks is standing facing a test field of N66; a new variety that the local SASRI extension service is trying out. This variety is also slow growing, as can be seen when compared to the younger field of N54 behind Ricks. That might be a part of the plan as there needs to be a variety to come alongside the slower growing, longer cycle N12. It’s too early to make any calls and, at the end of the day, a range of varieties is essential.

Notice the richer, darker Inanda and Nomanci soils on this part of the farm.

RIPENING

Ripening is new on this farm. Slow growing varieties generally have higher RVs but, as they move over to the faster growing, new varieties, ripeners can serve a purpose.

N54, 14 months old, ripened 5 days previously. Lying flat a few metres in.

N54, 14 months old, ripened 5 days previously. Lying flat a few metres in.

The Eggers’ are close to the mill and therefore have always tended to chase tonnage rather than sucrose when trying to maximise tonnes RV. They have felt that the growth achieved in those final 8 weeks, as opposed to the possible additional sucrose offered by ripening, gave the better outcome.

| Area average | Eggers | |

| Yield tonnes / hectare | 83 | 120 |

| RV % | 13.6 | 12.78 |

| Tonnes RV | 11.3 | 15.3 |

These sums show that, although their RV is below average, the high yield more than compensates.

They continuously trial theories though and, until recently, the result always substantiated their practice. But, trials on the new N54 have given different results and they are now seeing a definite benefit to ripeners in this fast-growing cane.

The lesson here is to be flexible and keep checking that your standard practices are still the best for your farm. Every situation is unique and the focus should be on your best possible outcomes, regardless of what you’ve always done historically or what the neighbours are doing.

Here Heinrich is showing me how the growth slowed in the recent dry spell (only 32mm when the average rainfall in January is normally 120mm). This climatic condition would have ripened the cane naturally so, when they harvest ripened fields this year it’s going to be difficult to know whether the higher RVs are a result of chemicals applied or the dry-spell-stress the cane experienced. As much as it would be appreciated, farming (and indeed life in general) is never a perfect science.

Here Heinrich is showing me how the growth slowed in the recent dry spell (only 32mm when the average rainfall in January is normally 120mm). This climatic condition would have ripened the cane naturally so, when they harvest ripened fields this year it’s going to be difficult to know whether the higher RVs are a result of chemicals applied or the dry-spell-stress the cane experienced. As much as it would be appreciated, farming (and indeed life in general) is never a perfect science.

Frost is also a natural ripener but, as it is inconsistent and ununiform, it is best to ripen before the frost season, thereby giving yourself some definites to work with. Very young cane (leaves only) will outgrow a touch of frost.

HARVESTING

The trusty Bell tri-wheeler ready to load some N54 seedcane. This machine manages 20 000 tonnes every season.

The trusty Bell tri-wheeler ready to load some N54 seedcane. This machine manages 20 000 tonnes every season.

All cane is burnt here. Heinrich explains that trashing is all but impossible in this climate. The heavy soils retain the low winter temperatures and a trash blanket would further exacerbate this situation, preventing effective germination. The cane tops are kept in-field though and are spread to boost the organic content of the soil.

Cutters place the cane in windrows (5 rows into one windrow) and a Bell three-wheeler loads in-field, into their own 27t truck. Cutters are given daily tasks and incentivised to go beyond that target.

I was interested in the soil compaction that some say this type of loading inflicts on the crop. Heinrich explained that compaction is a function of soils and slope. The wonderful soils on Sultan do not compact badly. Glenrosa soil forms, more prolific on their Nobel farm, compact more easily and replants are therefore more regular. The seasonal ripping of every field addresses any compaction issues.

Usually windrow harvesting cutters tend to leave a little too much stick … I was impressed to see how low this cutter had gone. Notice the sandier, more challenging Glenrosa soils on this part of the farm.

Usually windrow harvesting cutters tend to leave a little too much stick … I was impressed to see how low this cutter had gone. Notice the sandier, more challenging Glenrosa soils on this part of the farm.

WEEDS

Generally, there is a double-spray, the first one being just after ripping and fertiliser applications in the ratooning fields. They use a general product that has a residual value so that immediate rain is not essential. The second application comes a few weeks later, when the residual life of the first spray has expired. The chemical used is based on a visual inspection of which weeds are coming up. After that, any weeds that survive are hoed out.

The advice here is to perfect your timing; the age of the weeds and the cane as well as temperature and rainfall all play a part in the efficacy of herbicides. There is a new chemical that the Eggers’ use in spring and summer that burns the cane if used to late in the crop growth cycle; this affects canopying which allows enough light through at the right time to result in a Barbie grass epidemic. Apparently, the scientific name of Barbie grass is Panica Maximum for a good reason …

PESTS

N12 is fairly resistant to Eldana, probably because its slow growth rate means it has a dense, hard “skin”. The new, fast-growing varieties are far softer and therefore perfect Eldana-fodder. But this German army is ready and have already proven their intolerability when they sprayed an entire field after finding one Eldana … not 1 per 100 … ONE single insect! Besides the quick, decisive reaction to any pest, the general climate also helps keep bugs at bay.

MECHANICAL TOOLS

Predictably, the workshops are immaculate – a place you want to be in. If there are any farmers out there who keep meaning to tidy up their workshops but just never get to it, I’d suggest prioritising the task. Being in a well-organised, neat workshop allows a clarity of thought that will benefit your entire enterprise more than you can measure.

Notwithstanding the aspect of the landscape on these farms, Heinrich has researched mechanical harvesting intensely, even having visited Brazil to assess a whole-stick harvester but two main factors keep holding him back; the high running costs – this Midlands area has the most mechanical harvesters in the country but, because of the expense of running them, most are moth-balled. The second reason is the social responsibility to provide employment in the area.

As is already the case on numerous Midlands farms, mechanical technology in the spraying department is about to be implemented; Heinrich and Ricks are investing in GPS technology that will enhance efficiency and accuracy in spraying. It will shut off valves if the driver overlaps spray passes, thereby avoiding a double-dose of chemical AND saving money by eliminating wastage. The technology will also manage flow restrictions.

LABOUR

Sultan and Nobel employ 45 – 48 staff; mostly cane-cutters who also do hoeing. No staff reside on the property except for cutters who come from far away and need temporary weekly accommodation. All staff are fetched in the mornings and taken home in the evenings. It’s a very happy workforce with whom Heinrich enjoys interacting. Every morning they meet for a short devotional and discussion of current affairs; Heinrich explains things like petrol price increases, land reform or farm sales and how these things impacts their lives and the farming operation. It’s a two-way conversation and does a lot to enrich their relationships.

The temporary staff accommodation is pristine.

The temporary staff accommodation is pristine.

ADMINISTRATION

Heinrich enjoys the admin side of the enterprise; numbers, spreadsheets and accurate controls suit his personality (and his heritage). His desk is always neat and tidy. His advice is that this way of operating sets him up for success and I wholeheartedly agree, despite the fact that I have a 20cm thick pile of filing to my left as I type. Some of us are better suited to ‘order’ than others.

Administration of the whole business is made very simple by CanePro, which Heinrich uses extensively.

DIVERSIFICATION

Besides the 26 hectares of pine, the Eggers’ have also invested in some macs. When Ricks came back from studying, he was eager to diversify and had heard a lot about the rewards of macs. Heinrich, however, has always been a committed sugar farmer and has gone to great lengths to fully utilise the entire property to this end. So, when Ricks suggested macs, Heinrich agreed that perhaps they could try them out on some of the poorer soils on the Nobel farm. But Ricks had been advised to rather plant them close to the homestead, where the very best soils are. Mmmm – decision time. Do they pull out brand new cane fields, averaging 140t/h, to plant macs? Ricks had some homework to do … but, after much research and detailed costings, he managed to convince his dad that he be allowed to run with a 5-year plan that would see them develop 30 hectares of their very best soils to macs.

Ricks is now one of only 4 growers in this area who have ventured into macs; the oldest trees being 5 years.

The homestead, and the new mac orchards.

The homestead, and the new mac orchards.

They have planted Beaumonts, A4, 816, and have some A16 coming in. The orchards have micro-jet irrigation and Ricks is using the inter-row space to grow sunhemp (provides a small windbreak for juvenile trees) and erogrostis which is used as a mulch around the tree-base.

SUMMING UP

You’d think that after 8 hours, I’d be ready to leave but the warm hospitality I experienced with the Eggers family was enough to make me forget reality and settle in for good. I did promise not to elevate them in any way so I’ll reluctantly end my praises there.

Heinrich agrees with his compatriots when they tease him about farming in God’s own country and insists that you really can’t go wrong here – the average annual rainfall is 964mm and the soils are rich and deep.

If nothing else, Heinrich and Ricks can inspire us with their ‘way of being’ – to do everything to the best of your ability, and then some. Stay organised, disciplined and focused. I have no doubt that, if that’s all we took from this farm, it would be enough to add at least 15% to our results.

Here are a few more pics that begged to be shared:

Andrea runs a spectacular veggie and flower garden. Her and Heinrich are proud grandparents.

Andrea runs a spectacular veggie and flower garden. Her and Heinrich are proud grandparents.

And this is where I’ll leave you, with one final word to acknowledge the characteristic we all aspire towards, yet this family and community live out daily:

Thank you for having me – I look forward to our paths crossing again.