| Date | 28 February 2017 |

| Farmer | Dustin Cooper |

| Farm | Various – RD Heath |

| Area | KwaDukuza |

| Mill | Gledhow |

| Area under cane | 780 hectares |

| Distance from coast | 0 kms (Literally ON the beach) |

| Latitude | 29’ South |

| Dominant Soil type | Sandy |

| Cutting cycle | 14/15 months |

Hot February weather hung heavily as I made my way north to visit Dustin Cooper in KwaDukuza. He is a no-nonsense man who operates with a sense of purpose. He operates from a commercial office and workshop, as opposed to the other farms I have visited which are home-based offices. New experience. Far more quickly than I am used to, we settled into the interview.

Very thoughtfully, Dustin explained the history of Gledhow, which I found interesting: ownership was originally private, with sugar pioneers from the Smith, Reynolds, Pearce, and Crookes brothers involved. Then, in 1975, Illovo Sugar (then known as CG Smith Sugar) assumed ownership. 29 years later, in 2004 the mill and its 2000 hectares of cane fields was sold to a Black Empowerment company, headed up by Patrick Sokhela. In 2009, the majority of shares were bought out. The new shareholders were Illovo Sugar (30%), Sappi (10%), and local growers (25,1%). This new company was Ushukela Milling. As a part of this deal, the 2000 hectares of company owned cane was split into 300-400 hectare lots and leased to local growers. Enter RD Heath (who Dustin manages for) and many others … so, as far as I know, this is one of the only mills (Umfolozi has a similar history, also with the Sokhela family, but I am unsure whether all growers are owners in that situation) where every grower has a share … interesting.

And onto Dustin’s personal history … he’s a Mpumalanga boy. He grew up on a farm in the Barberton area where they grew mainly tobacco but also avos, macadamias and some micro-veggies. His dad passed away, and two years later, the farm was sold to land claimers. Dustin found his way to sunny KZN where he started managing for Balcombs in Kearsney. Rob Heath was contract harvesting in that area and the relationship began that sees Dustin now managing for him. I asked whether Dustin longs to have his own farm again but he says that he is given free-reign here and feels like it is his own so I guess that’s a no.

Beautiful seaviews.

Rob leases this farm and, in September 2016, bought his own, which Dustin also oversees. A total of 780 hectares of Eldana Central Headquarters. Being right on the coast, this noo-noo is alive and well and makes stretching for those 14 / 15 month growing cycles a challenge.

How did Dustin handle the drought? He raises the fact that this drought was actually very patchy and gives us great figures to assess the rainfall in comparison to other years: 2013 – 1135ml, 2014 -560ml, 2015 – 914ml, 2016 – 1104ml. So, the drought here was in 2014 when the rainfall was approximately half of the norm. But the crop from that period was greater than half the normal size. It was quite reasonable given the conditions. No crop roots were lost; the only impact was in the yield.

What did he do to survive so well ? Dustin says that, within reason, he advises farmers to continue farming as normally as possible. This is so that, as soon as the drought breaks, you have momentum and don’t struggle to catch up. It all boils down to understanding your capabilities and working around them … eg: if you do receive little bits of rain, use them wisely – plant if you can. Sugarcane is a VERY forgiving crop and not difficult to manage through a drought of the magnitude that they experienced in Gledhow. This needs to be taken in Dustin’s context – he comes from a background of farming miniature veggies where certain customers would stipulate a length of baby marrows (for example) of between 7 and 9 centimetres. This meant that they would often have to harvest twice a day given the rate of growth of these micro-veggies and the strict parameters set by supermarkets. That’s besides dealing with the myriad of creatures that like to snack on baby veg … oh – and NOTHING takes a weekend break … Yes – we can see how sugarcane is a walk in the park when you come from this background. Cheekily, I asked Dustin whether he ever felt lazy farming sugarcane. He said that I have just answered the main question I came here to ask: “What makes him one of SA’s Top sugarcane farmers?” Obviously, the fact that he is NOT lazy and, by applying the same attention to detail that he had to with his previous crops, into sugarcane, gives him amazing results. No less work, no less attention but a far more forgiving environment.

Not bad for 14 months

Fertilisers

Droughts happen. They’re a sure challenge that farmers will always face. Dustin seems to take them in his stride and simply work “with them”. In the realm of fertilisers, that entailed 3 things:

- Working within a revised cashflow. Harvest expectations have to be adjusted – accordingly, cut back on fertilizer, not only because there is reduced cash flow but also because the crop is not going to need as much fertilizer. The drought will stunt growth and no amount of fertilizer will rescue it.

- Take many soil samples to ensure that you only put down what is required, and no more. The average tonnage Dustin aims for is 80 per hectare – obviously, in a drought, crops are not going to reach their usual potential so the usual supplements will be superfluous.

- Split applications. Dustin does this regardless of the weather, and started this practice in 2006, but it is particularly important when in a challenging season. Gently feeding the crop what it needs and no more will save money and optimize the results. At the beginning of the season affected by the drought, he put down 50% of the fertilizer the crop required. The weather deteriorated and was so dry that the crop did not even need the other 50%. He therefore saved 50% of his fertilizer bill which went towards alleviating the stress on the bottom line.

A man who thrives on detail, making him one of the best farmers in our industry.

I am sure I am not the only one seeing a pattern here: Dustin definitely ‘walks alongside’ his crop, almost as though they’re chatting through the season, planning how, together they can get the best result. Very different to a farmer who thinks he can do it alone and follow age old regimes regardless of what the crop is saying to him. As yes – the plants do talk – soils talk – weather talks – there are so many elements out there, all shouting about what they need to be able to give you the best result. So, look at the crop, look at the weather, take soil samples, consider cash flow, consider maximum potentials in current conditions. Put them all together, formulate a plan and implement it, but don’t stop ‘walking with your crop’, listening to it telling you how to become a winner.

Urea or LAN ? Even here, Dustin tailor-makes his programme, taking the weather into account. In the beginning of the season, when it is traditionally drier, he will use a Nutriflow product, mixed with an ammonium nitrate-based nitrogen source. This LAN fertilizer comes mixed for him. So, in the beginning of the season, when volatilization is more of a concern because the rains are less, he uses LAN but closer to the end of the season, when it is wetter, he will use Urea based products. This clever use of options is possible because of the split applications and enables the application of necessary nutrients in forms that are ideal for the weather and take costs into account as well as providing the flexibility that might be required further into the season.

Dustin is not only splitting applications, he’s using different recipes. Genius !

Another note on applications – Dustin gets the fertiliser companies to handle the initial application. This is a busy time on a cane farm and as the only manager, looking after almost 800 hectares, he has to outsource come of the operations and this is one he feels is best handled by the suppliers. The second application, which is granular, is done by some of the cutting staff who have stayed on into the next season.

Lime and Gypsum. It is foundational (is that a word, or did I just make it up ?) that the soil ph is at a zero-acid level before anything is planted. Dustin advises that NO ONE even starts farming a field until acid levels are perfect.

My lesson in regrowth

Pesticides

As mentioned, Eldana is REAL in Dustin’s world. This is the first year that he is trying ‘scouting’. Really ? The first time you’re going to look for the little bugger ?

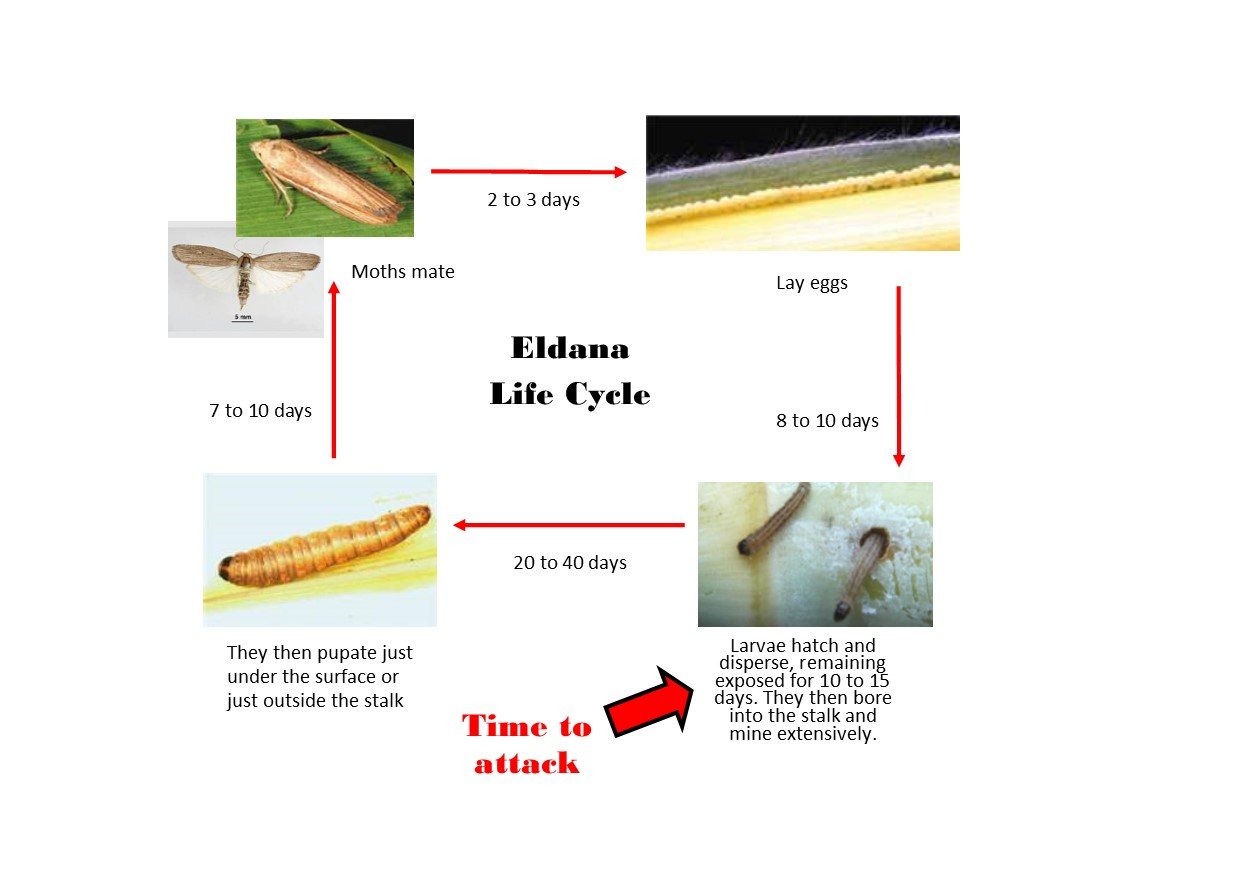

Up until now, Dustin has relied only on P&D’s figures. They supply percentage stalk damage and the number of eldana/ sestamia in that stalk per field, and then, usually, you spray according to that. Dustin has decided that spraying on this information alone is not only potentially harmful to the environment but also possibly wasteful. His thought process is based on his experience in other crops. This is the only crop where spraying is based on a damage report, rather than a proactive attack. Dustin is currently learning all about Eldana and trying to stay a step ahead by scouting (glad we cleared that up). Those challenged by Eldana all know the lifecycle of the critter – or, you should do if you employ the principle of knowing your enemies – so why not use that knowledge to be proactive.

If the moths are present, eggs come next. About 8 to 10 days after that, the worm emerges and exposes itself for about 10 to 15 days. Time for combat. Be prepared and ready with artillery that addresses the enemy BEFORE it has a chance to do too much damage. This little pest is quite temperature dependent so a close eye needs to be kept on that element of this war zone aswell. But, what Dustin is saying is use this window of vulnerability to spray rather than waiting until the worm has bored into the stalk and is safe from exposure to chemicals or, worse still, until it has had its fill of your sucrose and emerges to extend its family tree by another generation.

Dustin is very quick to add that they are sincerely grateful for the information provided by P&D and what he is doing is purely refining. My interpretation is that this is a classic example of what makes him a Top Farmer – the constant search for a way to improve and go the extra stretch. The choice between being reactive or proactive is the often the difference between mediocre and excellent.

Okay, what else are we fighting ? In the last 4 or 5 years there has been thrips, aphid and yellow aphid that have required spraying. Although it is difficult to quantify accurately, experts say that thrips alone could cause up to 10t per hectare damage. Ie: they suck chlorophyll from the leaves and reduce the plant’s growth efficiency by up to 10t per hectare. Obviously, that’s substantial enough to warrant spraying.

Gledhow mill in the distance. Proximity may be another reason for Dustin’s low harvest and haulage costs.

Herbicides

Timing – in this arena, Dustin believes this is the greatest challenge. That, coupled with knowing your farm; different weeds grow in different places on the farm. This means that blanket spray programmes should be reassessed to ensure that there is no unnecessary wastage. Chemicals used to attack weeds are not only costly but they can affect yield and plant health. In this last season, Dustin used 14 different chemical blends in a highly targeted assault on the unwanted invaders. How can this be possible ? By talking to chemical companies and reps who have experience in the area and have seen what is working on which weeds – Dustin is not above taking advice from anybody willing to guide him in continuing to be the best. (Yay – SugarBytes will even be read by the Top Farmers !)

Pre-emergence is how Dustin deals with the weed issue. He does not have time to be chasing aliens after they’ve taken root. First spray is 100% pre-emergent and then he does a second spray that is post-emergent with a mix of long term chemical. So, all fields are sprayed twice as a matter of standard. He then monitors to see whether any fields require a third spray. This way, his weeding units are very very low – he uses maybe 1 or 2 units per hectare.

Another pearl of wisdom in this area is to keep accurate records of spraying. Dustin has developed a tailored spread sheet that details when he sprayed which field and what the mix was. Herbicides will give you their cover period eg: 12 weeks, but that varies slightly farm to farm ie: ‘dirty’ farms may only enjoy an 8 week break and ‘clean’ farms might stay clear for 16 weeks. Dustin will capture his data and then, about 2 weeks before the chemical’s official life (according to the instructions) is over, he’ll start watching that field very closely – this enables him to get the longest possible stretch out of the chemical applied (thus maximizing the investment) whilst not allowing the weeds to get to the point where they will require labour. Perfecting the timing (only possible with accurate record keeping) minimises the expense involved in spraying too early (unnecessary waste of chemical) or too late (unnecessary waste of labour). And this is not as easy as it may sound: weather creates challenges which it likes to place right inside your window of opportunity … so, you identify your window in which you need to apply chemical and then gale-force winds ensue for the next 3 days !! Just as in anything else, it’s never as simple as it seems. Keep your eyes on ALL the balls simultaneously. Another winning quality the top farmers have.

No doubt that these are sandy soils

K.I.S.S. strategy.

Perhaps I am (again) giving away my age here but I remember being reminded often about Keeping It Simple Stupid while I was growing up. It seems the strategy has survived to Dustin’s generation as he encourages his fellow farmers not to overcomplicate things. There are some things we cannot worry about: the sugar price, the weather, the cost of diesel or chemicals. Instead, he advices that you spend that energy on areas you can control. And take heart from Dustin’s confidence that farming is pretty hard to get wrong. Personally, I find it intimidating and overwhelming: having so much out of your control – and maybe control freaks like me should steer clear of the occupation. Dustin reminds us that farming is fluid. Nothing should be cast in stone, everything should be tailored and relevant to your situation as you find it at the time. Work hard and in a thorough manner and the sweet grass will reward you with volume and intensity.

Farmers are natural optimists, making them wonderful to be around. So, if you’re in this game and you’re a born pessimist, perhaps the best advice is to abort. Be positive or move along. Kind of reminds me of another acronym I was brought up on: FIFO. For any who don’t know it, when I see you, ask me. No, it’s not First In, First Out.

Yellow yellow everywhere – even the trailers

Mechanisation

In this operation, which has a substantial harvesting component, equipment is used intensively. Rob began his business in harvesting and then became a farmer himself. A syndicate was created and the company, that Guy Heath (Rob’s son) now manages, harvests for all their neighbours. This means that machinery costs on Dustin’s farms is very low and makes a cut-and-stack operation less appealing. He is aware of the trend dictating that in-field mechanisation causes detrimental compaction but pure economics, in this situation, command continued use of this method. Yes, he might be planting fields more regularly because of the ratoon damage caused but, even that cost is less than the cost of using labour to harvest, because their current harvesting costs are so low.

This highlights a very important aspect of all the advice given here on SugarBytes … every farm and every business is unique. You need to make sure that you are doing the best you can FOR YOUR SITUATION. Having knowledge of what has worked for the Top Farmers (Sugarbytes’ mandate) only gives you knowledge, applying that (or not) to your circumstances is wisdom. And wisdom … well, wisdom is an elusive quality few are blessed with – the rest of us do our best with what we have.

Digression (more so than wisdom) seems to be my strength and here I am getting back on track … Dustin has done the analysis of his situation and mechanization works here. He advises that everyone be aware of their own costs and resources, do the sums and risk analyses and decide what makes sense for you. There is no room for sheep in this game.

So – this operation is all about mechanization which leads me to wonder about brands: a quick look out the window yields the answer – everything is yellow – Bell yellow.

“Have you ever considered anything that isn’t Bell ?”

“No.”

…

Dustin insists they’re strong, reliable and up to the task. Full stop.

In terms of tyres, Trelleborg All Terrain are used in-field. But Dustin warns to, again, be aware of cost: yes, the special tyres may ease the compaction effects of working in a field but the cost implication must be considered. With a significantly higher price tag, you must decide whether the cost of compaction is possibly less than the cost of the tyre.

I asked Dustin about what further input while we had mechanization on the table and he said something very valuable that applies to more than just this facet of farming: economies of scale – which applies universally. Basically, if you cannot do something cheaper than you can get someone else to do it for you, then don’t do it. So, if a contract harvestor offers his services at a more reasonable rate than it costs you to employ all the various resources that go into harvesting your cane – consider the contractor option.

If you are going to manage our own fleet, Dustin recommends GPS monitoring of all equipment so that it doesn’t take extended lunch-breaks or wayward routes home … ah – the challenges of employees everywhere … but, satellite tracking is a valuable tool available in this sector and should be utilized accordingly.

On a personal level, Dustin has a fully affiliated macadamia nursery which, given the current popularity of the nut, is a busy sideline. His wife, Charlene, manages this business. Obviously, Dustin is going to support diversification to macadamias but we investigate the reasons a little more closely: sugarcane is under pressure – the input costs increase more than the revenue does. Macadamias are experiencing such incredible growth in demand and subsequently prices increase. At the moment, China is the biggest market and prices continue to escalate by at least 10 to 15% annually. For cane farmers, this is attractive, hence the volume currently dipping their toes into the mac-world. A real road block to total diversification are the industry’s cane supply agreements with the mills. Like Dustin said earlier – address what you can, but that over which you have no control – don’t waste energy. Bottom line is: diversification is one of Dustin’s recommendations to the industry.

In terms of educating a farmer: Dustin says that agricultural college helped him create a solid foundation. Given the choice though, he thinks that a business degree might be more valuable simply because farming is something that comes more naturally than an understanding of finances and comprehending the lifeblood of all businesses (money) is essential, regardless of whether you stand in a field of cane or on the 35th floor of a skyrise. Similarly, keeping a grip on technology is also essential. The operating framework supporting so much of our lives and businesses is being imbedded with more and more technology, making an understanding of this field equally essential … so maybe a finance / technology qualification ?

Dustin spends about half his time in the office. He keeps all his own records and uses the time to track and forecast progress. While he utilizes some support programmes, like Plan-A-Head, for wages, he has a firm hand on the administration side of the operation which gives him perspective and context for all his farming decisions.

Dustin uses waste from Gledhow mill and incorporates it into the fields that are extremely sandy, giving them much needed mulch. Above you can just see a truck on the horizon and the many loads he’s delivered. Just past the horizon is the ocean. Below is a close-up of the waste delivered.

Discipline is a significant part of Dustin’s success. Being a farmer makes this characteristic valuable. In a world where no one is expecting you at the office at a particular time and there are a hundred shady spots to rest your weary bones, keeping your nose to the grindstone is all up to you. You cannot rely on anyone but yourself for motivation to do what needs to be done. Self-discipline is key. And now, as he points this out, I recognize this essential quality in each of the farmers I have interviewed thus far.

Pearls of wisdom

Attention to detail. At every step, consider every aspect. Don’t blaze through things or take short cuts or fail to consider things from all angles. Spend energy and time on details that can make a difference. Don’t waste energy or time on things that you have no control over.

“Consider vertical farming rather than horizontal farming.” Did that draw the same blank stare from you as it from me ? Dustin explains: “Instead of trying so hard to get more area under cane, rather strive for higher yield per hectare or consider other ways that you could increase your net income eg: simply by changing your use of that land. For example – supply quality seedcane, which gives a much higher return than cane going straight into the mill.” He has implemented this on his farm. Two years ago, Gledhow offered the opportunity for farmers to register as certified seed cane growers. He took up the offer and now makes a much higher return on these cane lands than on cane lands destined for the mill. There is a local heat treating plant across the road. Heat treating not only gets rid of the apical dominance challenge but also addresses the RSD.

Cages used to hold the seedcane when it is pasteurised

Last year Dustin sold about 2000 tonnes of seed. His own farm requires 800 tonnes of seed as all his seed cane fields are now certified seedcane. The first crop is sold as certified seedcane, the second, as commercial seedcane and the third is sent to the mill. So, instead of trying so hard to maximize area under cane, he focusses instead on the markets available, thereby earning more money off the hectares cultivated. He realized this alternative market during the drought (how often hasn’t a pressurized situation forced us to be creative and resulted in success beyond our expectations?) – looking around at the damage, he thought about all the farmers that would be needing seedcane as soon as the drought broke – so he went to work on providing a solution for that need. Gledhow mill invests in many of the black emerging farmers supplying their mill (50% of Gledhow’s suppliers are of this profile) and Dustin supplies them with quality seedcane. Next year, this operation needs to supply over 3000 tonnes of seedcane.

So, that’s what vertical farming is: making more money out of the same crop on the same area. Sounds like magic but it’s just wisdom.

Dustin has every right to be proud of his thriving seedcane fields, in this fertile valley.

And so ends my whirlwind visit with Dustin. The busy farmer whisks me around his vast operation – shows me all the important details and sends me off. All efficiency and professionalism. Very interesting and very inspiring. Thank you Dustin for bringing me a new take on so many aspects of successful sugar cane farming. You are a gem. And now the time has come to sum it up in a quote, and this was the easy part:

Dustin is proof that attention to detail results in great outcomes. Congratulations on being a Top Farmer at such a young age.

Hlahla Kahle, SugarBytes