Today is the 11 January 2021. I didn’t publish a December story and, if I don’t get through writing this one swiftly, there won’t be a January one either … 🤣 I have no excuses besides “It was 2020”, but I will share the events of last December so you have some measure of context …

I got a positive Covid result on 11th December.

And I had done a TropicalBytes farmer interview on the 10th!! “Please please please don’t let me have infected him,” I begged. But, in the same theme as 2020, Jaff soon got his positive result. Despite my continued prayers, he ended up in hospital and then ICU. I was completely unprepared for the guilt and anguish that comes with this awful virus and, for that alone, have developed an entirely new view of this pandemic. The experience has been hellish – I, myself, developed double pneumonia and was on the brink of hospital admission but, I would go through that all again if it meant that everyone I had infected, survived. Jaff was FINALLY released from hospital on 28th December (yes, he spent Christmas in hospital 😪) and is now recovering at home. Through it all he has been forgiving and genuinely concerned about my health! This Jaff will always hold a very special place in my heart and I celebrate his life every day. Wow – how our world has changed! And, I will most certainly be wearing a mask throughout ALL interviews from now on!!

I have debated about whether I should bring you Covid-Jaff’s story now or do I stick to the order in which I have interviewed the Jaffs? 🤔 I decided to go with the latter in the interests of minimising the time lapse between interview and publishing the story. So, Covid-Jaff’s article will be published in April 2021, God-willing!

And now, we skip back to B.C. (Before Covid) days. I still have 2 farmers from the trip I did to this prolific macadamia area in February 2020. Being the birthplace of macs in SA, all stories from these farmers are insightful. The wisdom they share, especially for newer mac farmers, is invaluable …

This Jaff is iconic – he is Chairman of one of the processors in the region, he is on the board of SAMAC and farming has run thick in his veins for generations.

He was born on this farm. His great grandfather was a Swiss missionary who started the local Elim hospital in 1895. Keeping it in the family, Jaff’s grandfather then ran the hospital after that. Jaff’s mother, aunts and uncles were all born on this farm. And, if Jaff’s children join the team, it’ll be the fourth generation to work this farm.

Something that keeps this farming family sustainable is that there are no guarantees of being employed on the farm – in fact, you are not allowed to join the team for at least 10 years after you finish school. Everyone needs to go off and establish themselves, for two reasons … one is so that, if you do come back into the farming business, you bring a skill or experience to the table. Two – so that you are equipped to do something other than farm, should Plan B ever be required. When Jaff’s time came to fly the nest, he studied Mechanical Engineering at WITS and then used these skills on diamond and coal mines for 10 years.

| FARM CONTEXT | |

| Date of visit | 12 February 2020 |

| Area | Levubu |

| Soils | 60% clay – deep reds and Huttons |

| Rainfall | Average 1300mm annually |

| Altitude | Average 800m |

| Temperature range | Av high: 40°C, Av low: 12°C. Typography means that temperatures vary vastly across the farms. Above average humidity. |

| Varieties | Main preferences now are 842, 849, Beaumont and 814 but there are many cultivars on this 45-year-old mac operation (inc 246, 660, 331) |

| Hectares under mac | 250, of which 120 are yet to come into production |

| Other crops | 60 ha Bananas

Timber |

Initially this farm grew citrus, timber and bananas. There is no longer any citrus and, up until a few years ago, there was no more timber either. A devastating fire in 1989 wiped out every stick. Bananas are the one constant throughout and Jaff currently farms 60 hectares of this valuable cash crop. They have tried a variety of crops through the years, including avos and pecans. In 2001, a year after the area had floods, every single avo tree died from phytophthora and that was actually the catalyst for a more focused commitment to macadamias.

Jaff is happy that their current line-up is best suited for all aspects of the operation: macs, bananas and a little bit of timber. For all you farmers who think it is hard to farm macs, Jaff says they’re easy compared to bananas which require year-round attention.

Bananas are a thirsty bunch.

The demanding nature of bananas may have been why Jaff’s dad was quick to try the macs … which he started planting 45 years ago. There was a lot of pioneering with these nuts at that time and Jaff Snr was brave enough to get involved. Since then, Jaff has expanded, with the most recent development being 120 hectares.

In the foreground, you can see part of the new development, while mature trees fill the distance.

Although Jaff has extensive administrative responsibilities, being on the boards of local organisations, he firmly believes that time in the lands is paramount to succeeding as a farmer, along with dedication, hard work (with LONG hours) and commitment. He spends about 40% of his day driving or walking in the orchards and plantations. While he loves his ‘job’, he warns new farmers that farming is not the ‘easy’ occupation it is often mistaken for.

Jaff strikes me as a perfectionist which is substantiated when he explains that there have to be set rules and that meticulous attention to detail is important. 90% correct is not good enough. He emphasises that we must stay close to the land and learn from the crop. Double check that what you are doing is right. If you’re failing, look at the plant to find the answers. He is grateful that he had the opportunity to study outside of agriculture – the education has equipped him with logic and practical problem-solving skills. In the development of the latest 120 hectares, Jaff has learnt that preplanning is key to success as the quality of the plan is the foundation of the venture.

Beyond that Jaff considers his family blessed by the farm they have, “High moisture and good soils are 80% of the battle won – I only have to bring 20% in the form of good management.” The climate is ideal and the soils are, mostly, deep red Huttons with a 60% clay content. Challenges are encountered with the extreme steepness of the farm: all vehicles are 4 x 4 and, when the weather is wet, all driving work stops. At least once a year, a tractor is rolled by someone who decides they can defy the forces of gravity but there are positives to the gradient: with such a high clay content in the soil, stagnant damp could become an issue but the slopes are used to manage drainage and it works well.

Looking back at the new development

This small area (shown on map below) has one of the highest rainfalls in SA. In the last 3 days alone (while I have been struggling to take pictures 🤨) 400mm has fallen. The average annual rainfall is 1300mm, which would be adequate to forego irrigation but unfortunately it doesn’t all fall when the trees need it. Average rainfall for the greater Levubu area is about 800mm. After these 400mm, Jaff says he won’t be able to access parts of the farm for another 3 to 4 weeks depending on how much more falls. This presents a challenge for pest control, especially as the nuts are so susceptible to damage right now.

Tucked in the ‘corner’ between Piesanghoek and the Soutpansberg mountains.

One of the greatest challenges this landscape presents is in spraying. Even fixed wing planes have deemed it too high risk, so Jaff contracts in a helicopter which comes to the area about every 4 weeks.

I am always frustrated at how a picture generally fails to capture gradient but maybe you will feel the pressure I had on the passenger side floor boards at this point? 🤣

This high precipitation, in a sheltered environment (minimal winds), results in higher than average humidity. Mac heaven!

CULTIVARS

On a farm that has been growing macs for 45 years, you’re bound to find almost every single variety but Jaff has settled on 4 for the expansion: 814, Beaumont, 842 & 849.

Twenty years ago, 788 was the ‘in’ thing … and so, about 20% of the farm was planted to this cultivar that has proven to be a disappointment for many in this region. Jaff is either taking them all out completely or top-working them to one of the 4 chosen cultivars. He has very few 788 left. The top-working started about 5 years ago and has been successful – most were top-worked with 814 and are bearing well. Jaff warns that whilst this route is a great solution to change cultivars it is labour-intensive, requiring lots of maintenance and pruning. Once the grafts have established and the old tree stops shooting, it settles down.

Some 816s have also been top-worked with 814 – more on this under Nurseries, below.

One of the cultivars on this farm that hasn’t particularly impressed, especially when compared with some newer varieties, is 344.

NURSERIES

Part of the vital planning process Jaff mentioned earlier is Nursery selection. Jaff recommends that you put time into this homework. Obviously SAMAC (and therefore SAGASA) approved nurseries are a good place to start but management is also important. You need to be sure any mishaps will be properly handled. Jaff experienced just this over the last couple years; he ordered 814 – specifically not 816 as he knows they don’t work well on this farm. The youngsters arrived and were nurtured and cared for as required. Their light colour leaves concerned Jaff and he tried fertilisers to correct what he hoped was just a nutrition issue (characteristically, 814s have darker leaves than 816s). Eventually, convinced that there was a mistake in the delivery, he called in the experts who confirmed his suspicions. The nursery concerned worked with Jaff to find the best solution, choosing to top-work the young trees in-field. There was a 50% take. The other 50% are being replaced with new plants. Had Jaff not been working with a reputable nursery, the outcome may not have been as fair. The experience taught him that management of, and controls in, each facility is paramount – make sure you get to know the nursery WELL before placing your order.

Top: 814 Below: 816.

While your order is in the nursery (that difficult +/- 18 month waiting period) go in and check the roots, making sure there is good, prolific growth. Keep an eye on insect problems too as thrips can be an issue in some nurseries.

Jaff has always preferred grafted seedlings to rooted cuttings because of the stronger root system. In his own small ‘back-up’ nursery, Jaff plants the seeds straight into bags to prevent J-rooting.

PLANTING

Good soils on hillsides means that Jaff can skip the landwork that most farmers have to invest in before planting. When comes to preparing the hole, Jaff warns against using an auger because it polishes the edge of the hole and makes it difficult for the roots to penetrate, especially in high clay like this – rather dig a square hole with a spade, a little deeper than the bag. He then mixes the soil with an equal quantity of compost. This is placed in the base of the hole as well as all around the roots. Finishing up with a ‘well’ on top and covering with more compost to help keep the soil cool and retain moisture.

This is one of the last blocks to be developed now that the blue gums have been removed. Notice the beautiful red soil.

Jaff will be trialing carbon-coated hydro-gel, for the first time, in next month’s plantings. He’s hopeful that it will ease the stress of getting to all the new trees with a water cart and is interested to see the benefits of the carbon for the micro-organisms.

Once the young trees are in the ground, treated support pegs keep them nice and straight. Fertilising starts right away.

When I asked about planting for cross-pollination, Jaff confirmed that, with the integs, they plant 3 rows and then one row of a cross-pollinator. In his view, hybrids do not require cross-pollination although he says some farmers are suggesting that Beaumonts and A4s could benefit from close proximity. The problem with putting anything else in a Beaumont orchard is that processors prefer Beaumont deliveries separate to other cultivars (because of the different roasting temperatures used on Beaumonts).

When it comes to pruning young trees, Jaff focuses on encouraging a central leader but does not use any manipulation on the side branches, believing instead that, in time, their weight will pull them down.

Because the new orchards have plenty of light, there is always a healthy amount of interrow growth. When mowed, this organic matter is raked around the base of the new trees.

Jaff has also had success with transplanting, as is seen in these 15-year-old 842s below. They needed to be moved when they were 5 years old. Choosing to do the move in late Spring (Nov / Dec), Jaff applied plenty of water to each tree and cut it back to about 2m high. As that left very few leaves, the stem and all remaining branches were painted with plain white PVA to prevent sun-burn. With the new holes pre-dug, a TLB carefully loosened the trees by scooping out the sand on all sides and then gently lifting the root bulb (and as much soil as possible) and placing it on a trailer. The TLB then lowered the trees into their new holes while soil and water was filled up around the base. Each tree was given about 100 litres of water and the existing micro-irrigation ensured that the roots were kept cool and moist. There was a 95% take.

Transplanted 842s showing strong regrowth from the point of the harsh prune before the move.

SPACING

“Spacing depends on your environmental factors,” says Jaff. Originally, his father planted 9m x 6m. But, 20 years ago (with 788s) they increased density to 8m x 5m. Jaff believes that, with the great soils, rainfall and temps on this farm, this is just too close. Pruning becomes a full-time job as the trees are fuelled to grow vigorously. So Jaff allows his trees a little more space and has settled on a standard spacing of 9m x 5,5m. Why 5,5m? The perfectionist-engineer likes the simplicity of having 200 trees per hectare and I am quite sure the trees appreciate the additional sunlight.

On a farm this steep, Jaff does not have the luxury of planting for aspect optimisation. The necessity here is that tractors can drive up and down slopes without rolling. He does mention that he has not recorded a marked difference between orchards, with regards to the rows’ aspect.

Looking through this orchard you can see that space is abundant and yet, there are still no open gaps. These are large, old trees.

This brand-new orchard has been planted at this farm’s standard 9m x 5,5m spacing. They are 1,5-year-old Beaumonts.

FERTILISER

Jaff uses ‘normal’ (5:1:5) fertiliser once a month from planting. The new trees get 25ml in hole and another 25ml on top. From then on, they each get 20g per month for the first year. This is in granular form, applied by hand.

With a farm this size it is very difficult to do individual field soil analyses. The blocks are small because of the topography – and there are probably about 60 to 70 blocks. In the past, Jaff has ordered specifically formulated fertilisers per area but the many years of farming have taught him that it hasn’t made a difference so now he uses a standard 5:1:5 across all orchards. The trees get an amount specific to their age and it is given 4 times per year. There’s a lot to be said for simplicity!

Jaff still does soil and leaf analyses with the aim of picking up other nutrient shortages and assessing soil acidity levels so that corrective lime can be applied.

Foliar feeds are tweaked according to leaf analyses but it is a pretty standard programme now: zinc, boron & copper applied in accordance with the phenology of the tree. He has tried a lot of the new ‘fancy’ sprays but doesn’t see the results to justify the input.

Composting is a focus activity on this farm. They make about 600 tonnes annually. The bananas produce a lot of rich organic waste, to which the mac husks, sawdust and kraal manure is added. Each tree gets 25 to 40kgs every second year and this boosts the organic content and microbial life around the roots. The enzymes that come with animal waste are vital – roughly a quarter of the compost is kraal manure.

Compost pile – these are left to ‘mature’ for 6 to 8 months before being used on the trees.

Compost in place. It has been purposely placed around the microjet so that all the nutrients are made accessible to the tree.

Mulching is generated in the interrows. All prunings are mulched and, before harvest, all leaves are raked out from under the trees and mulched. It all stays in the interrow rather than being pushed back under the tree.

IRRIGATION

Although rainfall is more than adequate, the timing is off so irrigation is required to deliver water in those dry months, from June to whenever the rains come – seems to get later every year.

Jaff has both drippers and microjets (on different farms). If water supply is adequate he would choose micros over drippers as he likes the visual reassurance that everything is working as it should. Although drippers are great for small trees, the micros wet a far larger area (and therefore encourage more expansive roots) and that’s why Jaff prefers them in mature orchards. A happy solution would be to design the irrigation system for micros but use button drippers until the trees are carrying a larger root base – then attach the micros into the dripper holes and change over.

Jaff put probes in about 7 years ago and suspects that they have cut back on water and timed the irrigation better since then. Pumps are used more efficiently so there has been an electricity saving as well. In terms of production though – he hasn’t seen a difference there.

This little off-shoot from the main river is flowing strongly after the 400mm that have fallen in the last week. Although gravity is used as much as possible, pumps are still required to take the water from the reservoirs to where it is needed, when it is needed.

A new reservoir is under construction on the new farm which extends down the hill – perhaps this picture gives a better idea of how steep the farm is.

PRUNING

Although pruning is an annual event, they only get to each tree every second year.

An All-cut, hedge pruner is used. Having discussed these implements with pruning specialists, I wonder why Jaff has chosen this route – he agrees that individual tree pruning would be better but they just don’t have the time to get around all the farms in 2 months.

This saw goes up to a 7m height but some trees are 3m taller than that, meaning that they ‘hang over’ the branches below.

All-cut hedging and the height of the trees can be seen in this picture.

The height is managed on an ongoing basis – Jaff assesses each tree individually and selects the tallest secondary leaders to cut out. Pest management nightmares also raced through my mind but then I remembered that this farm is sprayed aerially. They say that 80% of the stinkbugs live in the top 10% of the tree so maybe this all works well …

All-cut pruner

To create maximum visibility and access for harvesters, Jaff keeps the trees’ skirts a bit higher than normal at around 1,2m above the ground. These are also managed manually.

The high skirts on these tall 246s is nicely illustrated above.

DISEASES

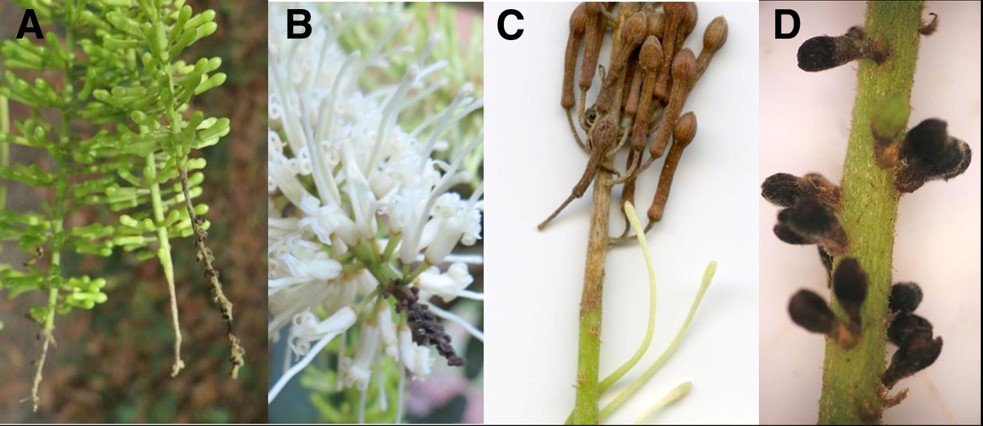

High humidity has its downside … and 2019 was a particularly bad year – Jaff’s macs picked up Dry Flower Rot (DFR) for the first time. Rats tail and Blossom Blight are issues they’re used to but DFR is new. Jaff reports that, before flowers even develop, they are dead on the raceme. At first, Jaff was unsure what he was dealing with but, by sending samples off to the university, he got confirmation. Luckily (through lots of time spent in the orchards) they picked it up when they did (and were able to spray with the right fungicide) as he has been warned that DFR has the potential to knock out an entire crop. To combat effectively, one needs to start spraying when flowers first start emerging. The challenge is that every fungus has a unique fungicide that needs to be sprayed; one for DFR, one for Rats Tail and one for Blossom Blight. Below is some information I found on www …

Incidence of dry flower disease of macadamia, expressed as blight of the flowers and necrosis and dieback of the rachis, is increasing in Australia. In the 2012-13 production season, incidence of dry flower disease resulted in 10 to 30% yield loss in the affected orchards. Etiology (origin) of the disease has not been established.

Fig. 1. Symptoms of diseased macadamia racemes associated with species of Pestalotiopsis and Neopestalotiopsis in Australia. A, Macadamia rachis dieback and necrosis; B, rachis dieback; C, flower blight and rachis necrosis at raceme stage 1 developmental period; and D, blight of newly formed flowers.

Credit to https://apsjournals.apsnet.org/ for this information.

Phytophthora is also becoming an issue in the macs lately, as is Armillaria a.k.a. Sudden Death Syndrome (SDS); this nasty fungus blocks all fluid transportation throughout the tree. As the name implies, the tree can die very quickly. In an effort to combat this, Jaff is applying a drench that contains a lot of phosphonics. Even if you catch it in time, recovery is a slow process, often taking a couple of years. Jaff has been applying the drench for about 4 to 5 years now and it is showing positive results.

Although the Armillaria fungus remains below ground, it can produce these mushrooms in certain conditions.

PESTS

Humidity and moisture may strengthen fungi but it is not good for thrips – from the thrips’ point of view. Jaff smiles when he says, “This wet weather we are having now means that we won’t see thrips for a long time – they are drowned out by the water and their life cycle is so short that they die out completely – until another swarm comes in of course!”

Unfortunately, the stinkbugs are not as susceptible to the rain and are rated Enemy number ONE on this farm. Jaff reports that, 20 years ago, they would spray maybe three times a year. Now, they have to spray every month and even then, it sometimes isn’t enough! The last spray was two weeks ago and, already, scouting counts today were too high.

Because this farm is literally on a mountainside, and has such high rainfall, using tractor spray rigs alone is not enough. Helicopters are contracted to spray the farms for two-spotted stinkbugs approximately every 4 weeks.

Jaff knows that the constant spraying is not a sustainable solution and looks forward to another, more ecologically-friendly answer being found soon. He is cognisant of the threat of resistance and constantly changes the chemicals used. Because there has to be a limit to how much is sprayed, he chooses not to spray for thrips or moths (FCM, MNB and Litchi moths are all found in these mac orchards). When the nuts are particularly susceptible to damage by these insects, he will use chemicals that are active for both thrips and stink bugs or moths and stink bugs.

Although Jaff is on a set spray programme, he still scouts. He uses the information for record-keeping and, if counts get too high, he will send in spray carts to handle pockets of outbreaks.

So, how do the spray carts reach these incredibly tall trees? Jaff has re-engineered his carts so that the fans are at a height of 4m. To compensate for the resulting top-heaviness, the axles have also been widened. Some carts have an additional modification in that electrostatic systems have been added; this charges the chemicals to a positive state. The tree is naturally negative so the chemical is attracted (positive –negative) and ‘sticks’. The efficacy is thereby enhanced.

LEFT: Spray cart with fan lifted to 4m to cater for the additional height of Jaff’s trees. RIGHT: this cart has an electromagnetic enhancement that charges the chemical to a positive. This “sticks” to the tree’s natural negative state and thereby enhances the efficacy.

The struggle to control stink bug populations in macadamia orchards is a real challenge, especially in Levubu – I’ve always wondered why they’re such a conundrum compared to other insects for which we seem to find multiple solutions … Jaff helped me understand: the most ecologically friendly way to control an insects population is to disrupt mating – like the pheromones we use in controlling the moths. By upsetting the communication between male and female, we reduce mating and next generation numbers. The problem with stink bugs is that they run THREE communication systems! Pheromones, sight and vibration. So, even if a pheromone was used, they’d overcome the issue by employing one of their other communication tools. Until we can find a way to deal with ALL their “chatter”, mating disruptions are an unlikely solution to stink bug control.

BEES

There are currently 70 hives across these farms. The goal is to have one hive per hectare; a total of 250. Don’t know about you but, immediately, my mind couldn’t place all these bees and all these chemicals in one operation, especially when I know the helicopters have to spray in daylight … so – I asked … Jaff explains that the bees are placed in sheltered, bushy areas at least 10 to 15m away from the orchard perimeters. Unless the macs are flowering, the orchards are largely empty of bees and, during flowering specifically, Jaff ONLY uses bee-friendly chemicals and sprays at night when the bees are in the hives. The surrounding banana and gum plantations as well as the natural veld, provide food when the macs can’t.

That said, swarm numbers are definitely decreasing. Usually, they catch 30 to 40 new swarms in a season but, in 2019, they only caught 5 or 6. It was an area-wide issue and a clear indicator that something is wrong …

The hives are permanent and Jaff maintains them by robbing the honey. This was an interesting concept to me (robbing = maintenance) and showed how little I know about these fascinating creatures – I was also reminded that I want to bring you an in-depth article on them this year as I can’t be the only one interested to know more about our life-sustaining, yellow-banded stingers.

The permanent beehives tucked safely into a sheltered bush area.

HARVESTING

Jaff has chosen not to use ethapon. Although he’s been assured that there is no adverse effect on the tree, the thick matt of leaves dropped by the tree after an ethapon dose makes him suspicious. Instead he uses sticks to hit the Beaumont nuts off – these orchards have not yet grown too tall for this harvesting method.

In preparation for harvest, the orchard floor is raked. All nuts on the floor are collected, dehusked and burnt. That’s something new … Jaff explains that he dehusks the nuts because the husks are very often still green and therefore don’t burn easily. He burns the nuts so that all insects (and there are usually a lot of residents in these nuts – that’s why they’re on the floor) are destroyed. It’s an important stage of orchard sanitation on this farm.

Harvesters are paid per kilogram with weighing happening in-field. From here the nuts are moved to the farm processing facility where they are placed into a ventilated hopper (with the high humidity and heat here, it is important that the nuts are not left to stand without ventilation as it risks mould and rancidity.

As soon as possible, the nuts are dehusked, sorted, bathed to remove floaters, tumbled to remove smalls and surface water, and put into drying bins.

Currently the bins are being upgraded to include a heating facility.

During the day, the heat from the shed ceiling is passed through the drying bins and through a sump filled with plain concrete bricks, which are heated in the process. At night, only air from the brick sump (which is now hot) is drawn through the bins, thereby creating 24 hours of (free) hot air.

For those chilly days when the ceiling won’t generate enough heat, electric heaters are also being installed. After the drying bins, the nuts are resorted and then loaded for delivery to the processing factory.

Busy modifying bins for heat component.

And, like the nuts, I am off! I trust you have enjoyed this candid chat with this industry leader. It was wonderful to be with someone so comfortable with his ‘place’ in the world. Jaff is a realist – unpressured by outside ‘noise’. He gratefully accepts the many blessing he has and graciously handles the challenges. Rather than chasing technology and expecting too much from your operation, he says that understanding, and operating within, your limits is key eg: if hand application of fertiliser works best on your farm – do it that way rather than feeling pressured to automate and mechanise unnecessarily. In Africa, we have a labour force that needs employment; working within their limits is also key to a mutually beneficial symbiosis.

This farm seems like a happy place – thank you, Jaff, for having me here and for sharing your insights.

Zoom in – and admire the heavy produce this little Beaumont has pushed out.

In February I’ll bring you a Jaffess! Yes, a girl Jaff 🤣. Isn’t that wonderful. Until then, God Bless and keep safe.

D